| Product | Product Id | Type | Rotation | Spring | Dust lip | Inside Diameter | Outer Diameter | Height | Dimensions | Material | Housing Material | Material Spring | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

76555 | Oil Seal | Yes | No | 65 | 105 | 10 | 65 x 105 x 10 | NBR - Nitrile | Black | 5 | € 9,56 | Details | ||||

|

76167 | Oil Seal | Yes | No | 60 | 80 | 12 | 60 x 80 x 12 | NBR - Nitrile | Black | 163 | € 7,44 | Details | ||||

|

74367 | Oil Seal | Yes | No | 12 | 20 | 5.5 | 12 x 20 x 5,5 | NBR - Nitrile | Black | 105 | € 2,41 | Details | ||||

|

73993 | Oil Seal | Yes | No | 20 | 35 | 6 | 20 x 35 x 6 | FPM - VITON | Steel | SS-304 | Brown | 595 | € 10,88 | Details | ||

|

71918 | Oil Seal | R-DRAL | Yes | No | 135 | 170 | 15 | 135 x 170 x 15 | FPM - VITON | Brown | 0 | € 76,76 | Details | Quote |

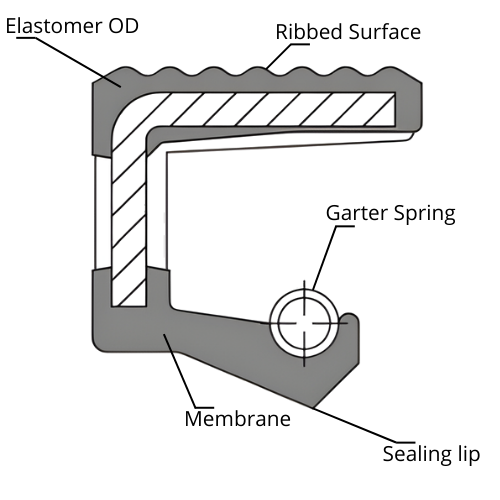

The G10 rotary shaft seal is made of a ribbed elastomer OD, a steel reinforcement ring and a flexible spring-loaded sealing lip. Together they form a sealing solution which is effective against leakage without compromising on durability or rotational performance. The sealing lip maintains in steady contact with the shaft, which creates a controlled oil film that minimizes both friction and wear. Due to this design of the oil seal G10 the sealing pressure stays maintained, even at temperature fluctuations or wear.

The ribbed outer shell plays a crucial role in installation and sealing. It adapts to surface irregularities and enhance grip within the housing, making the seal ideal for split housings or components made from aluminum or other materials prone to thermal expansion. The steel core of the G10 oil seal gives the construction the stability that it needs for an effective sealing without losing flexibility, even in challenging conditions.

The G10 rotary shaft seal is suitable for applications where rotating shafts are exposed to lubricants and environmental factors. In machine and equipment manufacturing which require precision and reliability, the oil seal G10 guarantees protection against lubricant leakage. It's commonly found in gearboxes, pumps, and compressors, components where seal performance directly affects lifespan and efficiency.

In agriculture and construction, machinery regularly endures vibration, temperature changes, and uneven installation conditions. The G10 oil seal thrives in these situations, thanks to its forgiving design and robust sealing performance. It's also a dependable option for electric motors and industrial drives operating at high speeds or under variable loads, assuming the material and dimensions are chosen to match the application.

The choice in materials for a G10 oil seal is crucial to its performance and its lifespan. NBR is the one of the most used materials because it has excellent oil and grease resistance, and excellent performance up to 100°C. The other commonly used material is FKM. This material is suitable for applications requiring chemical resistance and operating temperatures up to 200°C as it has superior resistance against heat and fuels and solvents.

For demanding environments involving wear, ozone exposure, or long service life, HNBR is an excellent choice, it blends mechanical strength with high thermal resistance. ACM is commonly used in automotive applications, especially for components exposed to hot oils and transmission fluids. Silicone rubber (VMQ), on the other hand, is great for extreme cold and oxidative environments, though it's less wear resistant.

EPDM and CR offer specialty performance in steam or water-based environments but are generally unsuitable for oil. As a result, they're used only in niche applications where petroleum resistance isn't required.

The standard metal components in the oil seal G10, such as the spring and reinforcement ring, are typically made from spring steel according to DIN EN 10270-1 and plate steel according to DIN EN 10139. For corrosive environments, stainless steel versions (1.4301) are also available on request.

|

Material |

Max. Temp. (°C) |

Key Properties |

|

NBR |

100°C |

Excellent oil and grease resistance, cost-effective, good wear performance |

|

FKM |

200°C |

High chemical resistance, excellent for fuels, solvents, and high temperatures |

|

HNBR |

150°C |

Strong mechanical properties, good heat and ozone resistance, long service life |

|

ACM |

150°C |

Ideal for hot oils and automatic transmission fluids, often used in automotive |

|

Silicone |

180°C |

Excellent low-temperature flexibility, good oxidative and thermal resistance, lower abrasion resistance |

|

EPDM |

120°C |

Good for steam, water, and brake fluids, not oil-resistant |

|

CR |

120°C |

Moderate resistance to weathering and ozone, limited oil resistance |

While the oil seal G10 and the SC oil seals share a similar core design, the G10 type stands out due to its ribbed rubber outer diameter. These ribs improve grip and static sealing, especially in housings with thermal expansion or less-than-perfect machining. In contrast, the SC oil seal uses a smooth rubber exterior and is best suited for tightly toleranced, standard-fit applications. That makes the G10 rotary shaft seal the more forgiving option when conditions are less than ideal.

The VG oil seal is structurally very similar to the G10 type oil seal. It has the same ribbed rubber outer diameter and a single sealing lip, but with one key difference: there’s no spring behind the lip. That makes the VG type better suited for applications with low shaft speeds or minimal pressure, where a lighter contact force is sufficient. Without the spring, the seal generates less friction, which can be helpful in low-energy systems or to reduce wear. However, it also means the sealing force isn’t as consistent over time, making the oil seal VG less ideal for dynamic or high-demand conditions. In short: if your application doesn’t require the extra tension of a spring-loaded lip, the VG offers a simple, cost-effective alternative.

Choosing the ideal G10 rotary shaft seal involves understanding both mechanical and environmental demands. Shaft and housing dimensions must fall within standard tolerances (typically ISO h11 and H8) to achieve a proper press-fit. The shaft’s surface finish also matters, a Ra value between 0.2 and 0.8 µm, along with a hardness of at least 45 HRC, helps minimize wear and leakage.

Temperature is another major consideration which must match the capabilities of the chosen elastomer. If your application exceeds 100°C or involves contact with aggressive fluids, a more heat- or chemically resistant elastomer such as FKM is essential. In cold conditions or at high speeds, it's important to consider how flexible the seal material stays. Some rubbers can dry out or lose their shape when exposed to too much stress or heat. The environment matters too. In dirtier situations, a seal with a dust lip, like the oil seal G11, is often a better choice because it offers added protection. Finally, make sure to account for the shaft's rotation speed, since higher speeds create more friction and heat, and your material needs to be able to handle that without breaking down.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The G10 has a single sealing lip and is suited for cleaner environments. The G11 adds a secondary dust lip, offering extra protection in dirty or abrasive conditions.

When made from NBR, it’s rated up to 100°C. If built with FKM, it can withstand temperatures up to 200°C.

Yes, it performs well with light, gas-like media if no pressure is involved. For pressurized gas, a different seal design is required.

It improves grip and sealing against the housing, particularly in housings with rough surfaces or thermal movement.

Absolutely. Its rubber ribs conform well to aluminum’s thermal expansion, maintaining a tight seal even under fluctuating temperatures.

Didn't find the right Oil Seal G10 - Rotary Shaft Seal?

Complete the form below and we will help you!