.jpg)

| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

74028 | Oil Seal | 40.03 | 74 | 10 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 |

Request

|

Details | Quote | |

|

73979 | Oil Seal | 69.85 | 90.07 | 12.7 | ACM | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |||

|

73980 | Oil Seal | 69.85 | 109.99 | 12.7 | ACM | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |||

|

73981 | Oil Seal | 14.28 | 28.53 | 13.48 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 190 | € 7,47 | Details | ||

|

73982 | Oil Seal | 15.87 | 28.53 | 13.48 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 73 | € 7,47 | Details | ||

|

73983 | Oil Seal | 69.85 | 90.07 | 11 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 31 | € 24,28 | Details | ||

|

73984 | Oil Seal | 106.35 | 130.15 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 52 |

Request

|

Details | Quote | |

|

73985 | Oil Seal | 101.6 | 126.89 | 7.93 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 384 | € 37,58 | Details | ||

|

74026 | Oil Seal | 53.98 | 79.35 | 9.53 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 1430 |

Request

|

Details | Quote | |

|

74027 | Oil Seal | 69.85 | 88.9 | 9.53 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 32,04 | Details | Quote | |

|

76302 | Oil Seal | 70 | 95 | 12 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 820 | € 28,26 | Details | ||

|

74029 | Oil Seal | 53.98 | 90 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 495 |

Request

|

Details | Quote | |

|

74187 | Oil Seal | 80 | 100 | 10 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 282 | € 20,83 | Details | ||

|

74320 | Oil Seal | 110 | 140 | 15 | NBR - Nitrile | Yes | Yes | Black | 24 | € 14,23 | Details | ||||

|

75074 | Oil Seal | 25 | 37 | 6 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 69 | € 12,70 | Details | ||

|

75123 | Oil Seal | 26 | 37 | 7 | NBR - Nitrile | Yes | Yes | Black | 274 | € 3,24 | Details | ||||

|

75290 | Oil Seal | 30 | 41 | 7 | NBR - Nitrile | Yes | Yes | Black | 0 | € 3,71 | Details | Quote | |||

|

75891 | Oil Seal | 47 | 73 | 10 | NBR - Nitrile | Yes | Yes | Black | 0 | € 7,06 | Details | Quote | |||

|

75961 | Oil Seal | 50 | 68 | 10 | NBR - Nitrile | Yes | Yes | Black | 52 | € 6,42 | Details | ||||

|

76001 | Oil Seal | 52 | 68 | 10 | NBR - Nitrile | Yes | Yes | Black | 623 | € 6,42 | Details |

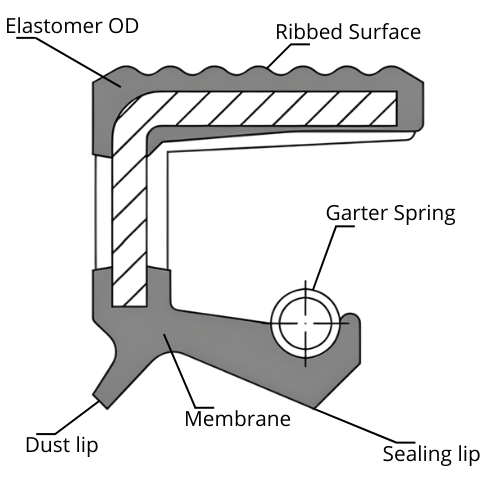

The oil seal G11 consists of multiple functional components which ensure a reliable sealing together. The primary sealing lip is in contact with the rotating shaft and is supported by a steel garter spring, which ensures a constant radial pressure. This helps maintaining a stable sealing, even in the presence of wear, temperature changes or varieties in radial speed. During operation, a thin lubricating film forms between the lip and shaft, which reduces friction and wear.

On the air side, a secondary dust lip is installed. This lip prevents dust, dirt, or moisture from the outside from reaching the primary sealing lip and, especially in contaminated environments, contributes to a longer service life and stable sealing performance.

The outer diameter is fully elastomer-coated and provided with a ribbed structure. These ribs ensure additional grip in the housing and make the oil seal tolerant of deviations in roundness, surface roughness, and thermal expansion, particularly in light-metal or split housings. Because no metal outer case makes direct contact with the housing, there is no risk of fretting corrosion. This makes the G11oil seal suitable for dynamic sealing in pressureless applications, even when installation conditions are less than ideal.

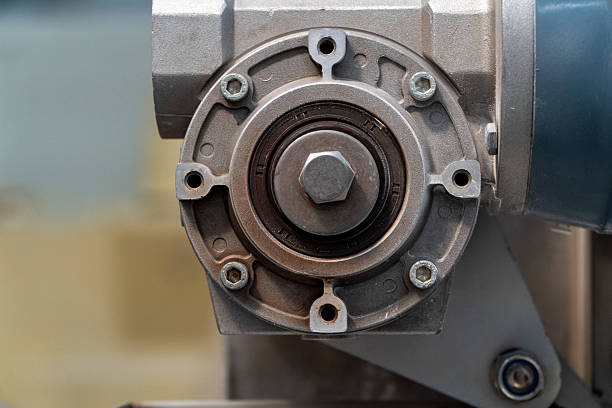

The G11 oil seal is used in a wide range of machines and installations where rotating shafts must be reliably sealed. Typical applications can be found in machine and equipment construction, where oil seals are used in drives, bearings, and transmissions. The G11 rotary shaft seal is also commonly used in industrial drivers and gearboxes, to keep lubricants inside and to protect internal components against external contamination.

In addition, this oil seal G11 is suitable for electric motors which require a reliable sealing to protect bearings and windings. In agricultural machinery and construction equipment, the G11 oil seal is used because of its resistance to dirt and its tolerance for thermal expansion and vibration. In these environments, where dust, mud, and fluctuating temperatures are common, the combination of a dust lip and a ribbed elastomer-coated outer diameter proves particularly effective.

The standard G11 rotary shaft seal is made in NBR, FKM or ACM. NBR is commonly used due to its excellent resistance against mineral oils and greases, favourable wear properties and its relative low price. It can handle temperatures from -40°C up to +100°C, but +80°C is recommended when there will be contact with synthetic lubricants. This makes NBR suitable for a wide range of standard industrial applications, but it’s less suitable for higher temperature or aggressive chemicals.

For more demanding conditions, alternative elastomers are available. FKM is mostly chosen when working with high temperatures and increased chemical exposure, for example hot oils or additives. ACM is used at higher temperatures in combination with specific oils, such as in drive systems. HNBR offers a higher mechanical strength and better heat- and ozone resistance than standard NBR and is suitable for heavily loaded applications. Silicone maintains excellently flexible at lower temperatures but has lower mechanical wear resistance. CR (neoprene) and EPDM are used for specific media or environmental influences but are not universally suitable for oil.

The garter spring and the reinforcement ring are typically made of steel but are also available in stainless steel (1.4301) when additional corrosion resistance is required. The choice of material largely determines whether the oil seal G11 is suitable for a specific application: the construction remains, while the compound is selected based on temperature, medium and required life span.

|

Material |

Typical temperature range |

Strengths |

When to choose |

|

NBR |

-40 °C to +100 °C (recommended ≤ 80 °C with synthetic oils) |

Good wear resistance, suitable for mineral oils and greases, cost-effective |

Standard industrial applications with oil or grease |

|

FKM |

-20 °C to +200 °C |

Excellent heat and chemical resistance, long service life |

High temperatures, aggressive lubricants or additives |

|

HNBR |

-30 °C to +150 °C |

High mechanical strength, improved heat and ozone resistance |

Heavily loaded applications and modern lubricants |

|

ACM |

-20 °C to +150 °C |

Good resistance to hot oils and oxidation |

Drives and transmissions at elevated temperatures |

|

VMQ |

-50 °C to +180 °C |

Very flexible at low temperatures, good thermal stability |

Low-temperature applications with limited mechanical load |

|

CR |

-30 °C to +120 °C |

Moderate oil and weather resistance |

Specific environments with moderate oil exposure |

|

EPDM |

-40 °C to +150 °C |

Excellent resistance to water, steam, and weathering |

Non-oil applications, such as water or brake fluid |

The G11 oil seal shows obvious similarities to other oil seals from the same family but differs in various important factors. Compared to the G10 oil seal, the G11 oil seal has an additional dust lip. Both types contain a spring-loaded main lip and an elastomer coated outer diameter but the oil seal G11 offers additional protection against external contamination, which makes it better suitable for dusty or dirty environments.

Compared to the G13 oil seal, the most important difference is the presence of the steel garter spring. The G13 does include a dust lip but does not have spring support. As a result, the sealing pressure is lower, and this type is primarily intended for simple, lightly loaded sealing applications, such as grease sealing or low rotational speeds. Thanks to the spring, the G11 offers more reliable sealing with low-viscosity lubricants and in dynamic applications.

In comparison with standard elastomer coated TC oil seals, the G11 oil seal stands out mainly due to its ribbed outer diameter, which allows for greater tolerance in the housing. This makes the oil seal G11 a preferred rotary shaft seal for applications where a standard smooth outer shell does not provide sufficient reliability.

When selecting the correct G11 oil seal (despite the heading), it is important to look beyond size alone. First, the shaft diameter, outer diameter, and width must be selected correctly according to the applicable dimensions. It is essential that both the shaft and housing meet the correct tolerances. For the shaft, a tolerance according to ISO h11 is recommended, with a minimum hardness of 45 HRC and a fine, torsion-free surface finish. The shaft surface roughness must be low to prevent wear and leakage.

The housing should meet a tolerance according to ISO H8. Thanks to the ribbed elastomer-coated outer diameter, the G11 can accommodate a slightly higher housing surface roughness, but a correct fit remains crucial for secure static sealing. Operating conditions such as temperature, rotational speed, and type of lubricant also play an important role. For pressureless applications with oil or grease, the G11 is a suitable choice, provided that the temperature and media specifications remain within the limits of the selected material.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

Een G11 oil seal wordt gebruikt om olie of vet af te dichten rond roterende assen en tegelijkertijd externe vervuiling buiten te houden in drukloze toepassingen.

Het verschil zit in de stoflip: de G11 heeft een extra stoflip, terwijl de G10 alleen een veerondersteunde afdichtlip heeft.

Nee, de G11 is bedoeld voor drukloze toepassingen en kan slechts een zeer lage druk aan (maximaal circa 0,05 MPa).

Dat hangt af van temperatuur en medium. NBR is geschikt voor standaard oliën, terwijl FKM of HNBR beter zijn bij hogere temperaturen of agressievere media.

Ja, de geribbelde elastomeer buitendiameter maakt de G11 geschikt voor behuizingen met verhoogde ruwheid of thermische uitzetting.

Didn't find the right Oil Seal G11 - Rotary Shaft Seal?

Complete the form below and we will help you!