| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

47941 | Oil Seal | 5 | 14 | 5 | NBR - Nitrile | Steel | No | Yes | Black | 0 | € 2,65 | Details | Quote | |

|

46648 | Oil Seal | 45 | 62 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 854 | € 6,69 | Details | ||

|

46649 | Oil Seal | 64 | 82 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 1408 | € 7,55 | Details | ||

|

47107 | Oil Seal | 13 | 20 | 5 | NBR - Nitrile | Steel | No | Yes | Black | 2233 | € 2,65 | Details | ||

|

47111 | Oil Seal | 130 | 150 | 11 | NBR - Nitrile | Steel | No | Yes | Black | 79 | € 16,49 | Details | ||

|

47411 | Oil Seal | 22 | 32 | 3 | NBR - Nitrile | Steel | No | Yes | Black | 527 | € 3,05 | Details | ||

|

47669 | Oil Seal | 32 | 52 | 9.5 | NBR - Nitrile | Steel | No | Yes | Black | 2231 | € 5,47 | Details | ||

|

47772 | Oil Seal | 38 | 50.3 | 10 | NBR - Nitrile | Steel | No | Yes | Black | 163 | € 5,47 | Details | ||

|

47785 | Oil Seal | 39 | 52 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 1488 | € 5,47 | Details | ||

|

47787 | Oil Seal | 39 | 54 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 1720 | € 5,44 | Details | ||

|

47802 | Oil Seal | 40 | 55 | 8 | NBR - Nitrile | Steel | No | Yes | Black | 3651 | € 5,44 | Details | ||

|

47840 | Oil Seal | 42 | 58 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 1925 | € 5,89 | Details | ||

|

47845 | Oil Seal | 43 | 50 | 9 | NBR - Nitrile | Steel | No | Yes | Black | 2451 | € 4,93 | Details | ||

|

47913 | Oil Seal | 46 | 62 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 336 | € 6,69 | Details | ||

|

47920 | Oil Seal | 47 | 84 | 12 | NBR - Nitrile | Steel | No | Yes | Black | 40 | € 7,55 | Details | ||

|

47937 | Oil Seal | 49 | 56 | 9 | NBR - Nitrile | Steel | No | Yes | Black | 816 | € 5,98 | Details | ||

|

51553 | Oil Seal | 114.3 | 152.4 | 6.35 | NBR - Nitrile | Steel | No | Yes | Black | 25 | € 18,01 | Details | ||

|

47948 | Oil Seal | 50 | 63 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 1444 | € 6,69 | Details | ||

|

47992 | Oil Seal | 51 | 63 | 6 | FPM - VITON | Steel | No | Yes | Brown | 88 | € 22,68 | Details | ||

|

47993 | Oil Seal | 51 | 63 | 9 | NBR - Nitrile | Steel | No | Yes | Black | 2082 | € 6,69 | Details | ||

|

48177 | Oil Seal | 70 | 90 | 10 | NBR - Nitrile | Steel | No | Yes | Black | 180 | € 8,16 | Details | ||

|

48280 | Oil Seal | 85 | 115 | 13 | NBR - Nitrile | Steel | No | Yes | Black | 143 | € 12,23 | Details | ||

|

48282 | Oil Seal | 85 | 115 | 14 | NBR - Nitrile | Steel | No | Yes | Black | 100 | € 12,23 | Details | ||

|

51431 | Oil Seal | 12.7 | 17.46 | 4.76 | NBR - Nitrile | Steel | No | Yes | Black | 376 | € 2,65 | Details | ||

|

51439 | Oil Seal | 14.28 | 28.57 | 13.5 | NBR - Nitrile | Steel | No | Yes | Black | 511 | € 2,65 | Details | ||

|

51475 | Oil Seal | 25.4 | 50.8 | 6.35 | NBR - Nitrile | Steel | No | Yes | Black | 124 | € 5,47 | Details | ||

|

51519 | Oil Seal | 52.44 | 82.55 | 4.76 | NBR - Nitrile | Steel | No | Yes | Black | 153 | € 7,55 | Details | ||

|

51527 | Oil Seal | 58.75 | 88.9 | 4.57 | NBR - Nitrile | Steel | No | Yes | Black | 22 | € 8,16 | Details | ||

|

51538 | Oil Seal | 74.63 | 104.78 | 5.56 | NBR - Nitrile | Steel | No | Yes | Black | 927 | € 10,43 | Details | ||

|

51539 | Oil Seal | 75 | 106 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 310 | € 11,48 | Details |

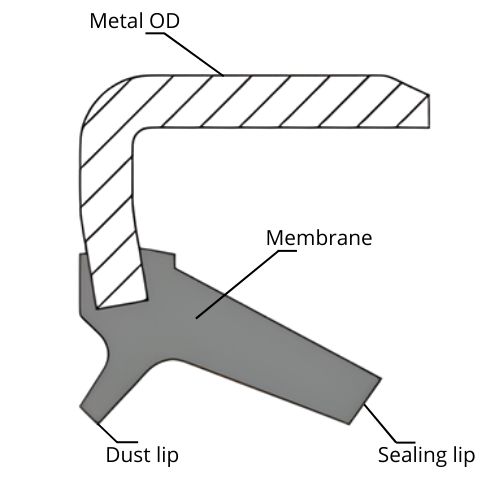

A KB oil seal is a rotary shaft seal with two sealing lips: one to keep lubricants like grease or oils inside, and one to prevent external contamination like dirt or moisture from entering. In comparison to spring-loaded oil seals, the oil seal KB type relies completely on its natural elasticity to keep pressure on the rotating shaft. The metal outer diameter ensures a secure interference fit in the housing, which makes this oil seal a stable and reliable choice for applications where vibrations and temperature changes are present. Do keep in mind that this applies only when there is no internal system pressure.

Because the oil seal KB type is designed to operate in systems without internal pressure, it performs best in filled with grease applications and where minimal friction with the rotating shaft is preferred. By excluding the garter spring, the design reduces torque, limits heat generation, and minimizes wear on both the shaft and the seal lip. This contributes to extend the lifespan of the sealing, especially in environments with constant lubrication and moderate shaft rotation speed. The second lip, also known as the dust lip, serves as a barrier to protect the main sealing lip against external contamination. Thanks to this configuration, the KB oil seal offers a reliable double sealing without the complexity of a spring-loaded oil seal. The metal outer shell adds to its structural integrity and simplifies accurate alignment during installation. The oil seal KB type has a compact profile which is suitable for applications with limited space available.

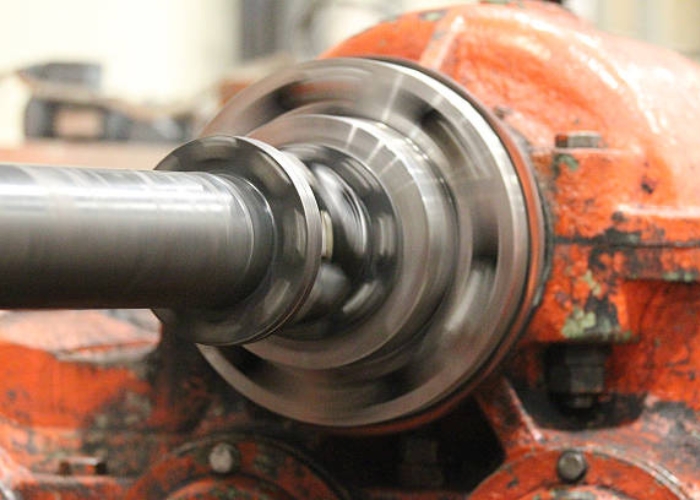

In everyday industrial use, the KB oil seals are commonly found in mechanical constructions that don’t require pressure sealing but do demand a consistent lubricant retention and protection against external contamination. For example, gearboxes, electro motors, agricultural machinery and industrial rollers, environments where lubricated shafts rotate with moderate speed and are being exposed to dirt or moisture/splash water. The combination or a springless lip design and a strong mechanical fit makes the KB oil seal exceptionally suitable for machines where uptime and maintenance intervals are critical. The rotary shaft seal keeps performing reliably in heavy environments as long as the system has no internal pressure.

The standard KB oil seals design consists of an elastomer sealing lip (commonly made of NBR), which offers great flexibility and oil resistance at temperatures between -40 and +100. This is paired with a metal OD that delivers mechanical strength and precise fitting. For applications that require resistance against high temperatures, aggressive chemicals or wear, alternate materials like FKM, HNBR, EPDM ACM, CR or VMQ are available. Which of these materials you should choose depends on the applications needs. New synthetic lubricants should be tested before regular use. With synthetic oils, the temperature must not exceed +80°C unless confirmed by testing.

| Material | Temperature Range | Key Properties |

|---|---|---|

| NBR | –40°C to +100°C | Good oil resistance, cost-effective, flexible |

| FKM (Viton®) | –25°C to +200°C | High heat and chemical resistance |

| HNBR | –30°C to +150°C | Wear resistant, heat and oxidation resistant |

| ACM | –20°C to +150°C | Heat and oil resistant, moderate elasticity |

| Silicone | –60°C to +180°C | Excellent thermal range, low friction |

| EPDM | –40°C to +150°C | Resistant to water, steam, brake fluid; low oil resistance |

| CR | –30°C to +120°C | Good weather and ozone resistance |

When comparing the KB oil seal to similar rotary shaft seals, two key alternatives are often considered: the KC oil seal and the TB oil seal. Just like the KB type, the KC oil seal shares the same double lip, no spring design, but differs by having an elastomer outer diameter instead of a metal shell. This makes the KC type oil seal more forgiving in light metal or slightly rough bores, where a metal-to-metal press fit might pose a sealing risk. The oil seal BK on the other hand, with its metal OD, offers higher structural stability, especially in steel or cast-iron housings that are machined to tight tolerances. It’s also less sensitive to shifting under thermal expansion or vibration.

The oil seal TB contains a garter spring to secure the sealing lip in place and maintain pressure in low-pressure environments. The TB oil seal is suitable for systems with little internal pressure and dynamic shaft movement but generates higher friction and requires more complex installation. The oil seal KB on the other hand is great for lubricated applications with no pressure and offers a smoother performance with reduced energy loss and simpler handling.

Successful performance of the KB oil seal depends heavily on proper shaft and housing preparation. Shafts should meet ISO h11 tolerances and have a surface hardness of at least 45 HRC. Housing bores should conform to ISO H8 fits and maintain a clean, smooth surface. In cases involving light alloy housings or above-normal surface roughness, applying a thin layer of sealant to the outer diameter may improve static sealing. Alternatively, a version with a coated OD is available to address such challenges. Be cautious when using the seal in light metal housings or rough bores. A sealant or coated OD may be needed. Shafts should be 45 HRC or harder. Surface roughness should be Ra 0.2–0.8 μm. Housings need Ra 0.8–3.2 μm and Rmax ≤ 16 μm.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

No, KB oil seals are specifically designed for pressureless systems. They rely on rubber elasticity for sealing force and are not equipped to withstand internal pressure. For pressurized applications, a spring-loaded seal such as the TB type is recommended.

While both KB and KC seals feature a dual-lip design without a spring, their outer diameters differ. The KB has a metal outer shell, providing a firm press-fit in precisely machined housings. The KC, with its rubber-coated OD, is more suitable for housings with irregular surfaces or made from light alloys.

Reusing a KB oil seal is not recommended. Once removed, the sealing lips may deform, compromising the integrity of the seal. For optimal performance, a new seal should always be installed.

Standard options include NBR for general oil resistance. For higher temperatures or chemical exposure, materials like FKM, HNBR, or silicone rubber can be used. Stainless steel or coated housings are also available for specific environments.

Didn't find the right Oil Seal KB - Rotary Shaft Seal?

Complete the form below and we will help you!