| Product | Product Id | Type | Spring | Dust lip | Material Spring | Inside Diameter | Outer Diameter | Height | Color | Material | Housing Material | Rotation | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

61431 | Oil Seal | Yes | 42 | 72 | 7 | Black | NBR - Nitrile | Steel | 241 | € 6,99 | Details | ||||

|

61409 | Oil Seal | Yes | 28 | 35 | 4 | Black | NBR - Nitrile | Steel | 292 | € 2,79 | Details | ||||

|

61369 | Oil Seal | Yes | 12 | 24 | 5 | Black | NBR - Nitrile | Steel | 2347 | € 2,41 | Details | ||||

|

61358 | Oil Seal | Yes | 8 | 18 | 5 | Black | NBR - Nitrile | Steel | 4253 | € 2,41 | Details | ||||

|

61346 | Oil Seal | Yes | 4.8 | 15.5 | 5.5 | Black | NBR - Nitrile | Steel | 613 | € 2,41 | Details |

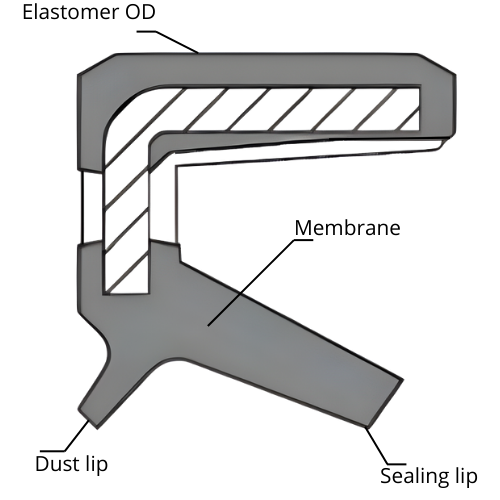

The KC oil seal features a dual-lip configuration molded around a single metal insert. The primary sealing lip is in direct contact with the shaft, maintaining a light pressure that keeps grease or oil inside the system. Unlike other common shaft seals such as the oil seal TC type, the KC rotary shaft seal its lip is not reinforced by a garter spring. Instead, it relies completely on the elasticity of the rubber to keep radial pressure on the rotating shaft. This results in less friction between the shaft and the oil seal, which causes less wear and heat generation during operating time.

The second dust lip is placed at the air side of the seal and faced outward to prevent contamination to come enter. This extra barrier helps extend the lifetime of the main sealing lip by protecting it from debris. The rubber outer diameter helps maintaining a reliable sealing against the bore, even in housings with small imperfections or thermal expansion.

The absence of a metal outer shell makes the oil seal KC type more tolerant of bore surface deviations while maintaining excellent vibration damping.

During installation, it is important that the area between the two lips is filled with a small amount of grease. This provides initial lubrication at startup and prevents dry running of the lips. KC oil seals are typically installed flush with the housing surface and do not require axial retention beyond a correct press fit. Because the seal lacks a spring, it should not be used in systems that build up internal pressure. For specific applications requiring chemical resistance or temperature tolerance, the KC oil seal can be selected in variants made from FKM, Silicone, ACM, HNBR, CR or EPDM.

KC rotary shaft seals are commonly used in low-pressure environments where oil or grease must be retained and contamination excluded. Their low-friction design and dual-lip construction make them well suited for electric motors, small gearboxes, agricultural machinery, power tools and industrial housings filled with high-viscosity lubricants. The absence of a metal casing allows for smooth integration in housings that are subject to slight deformation or dimensional variation.

In many cases, the oil seal KC type is used as a secondary seal in combination with another main seal to reinforce protection against environmental contamination. It is particularly effective in outdoor or dusty conditions where the outer lip reduces the ingress of mud, sand or water. This seal is commonly used in grease-packed assemblies or splash-lubricated systems without direct fluid pressure, because it isn’t suitable for high pressure applications. Depending on the environment and the lubricant, you can choose from materials like FKM, Silicone, ACM, HNBR, CR or EPDM to optimize the performances of the seal.

KC oil seals are available in a variety of elastomer compounds, each selected for its performance in specific operating conditions. The standard material option is NBR, suitable for mineral oils and temperatures between -30°C and +100°C. For higher temperatures or aggressive fluids, FKM is the preferred material which can handle temperatures up to +200°C. If there’s exposure to ozone, weathering of synthetic fluids, EPDM or HNBR may be appropriate. For low temperature applications of food-grade sealings, Silicon (VMQ) could be the right choice. ACM and CR are commonly used in industrial operations where oil-, oxidation- and heat resistance are required.

Each material offers a different balance between flexibility, wear resistance and fluid compatibility. The right choice in material depends on shaft rotating speed, temperature, lubrication type and exposure to external factors. The metal insert is commonly made of carbon steel and partially coated in elastomer, providing support while allowing press-fit rigidity. Full rubber encapsulation applies only to plus-type variants.

While NBR is the standard material for the oil seal KC, materials like FKM, EPDM, HNBR, Silicone, ACM and CR are available on request.

|

Material |

Temperature Range |

Advantages |

|

NBR |

-30 °C to +100 °C |

Good general resistance to oils and greases |

|

FKM |

-20 °C to +200 °C |

Excellent resistance to heat and aggressive chemicals |

|

Silicone |

-60 °C to +180 °C |

Flexible at very low temperatures, food-grade compliant |

|

ACM |

-20 °C to +150 °C |

Strong resistance to oxidation, oil, and moderate heat |

|

HNBR |

-30 °C to +150 °C |

High mechanical strength, ozone and heat resistant |

|

CR |

-40 °C to +120 °C |

Good resistance to weathering, ozone; moderate oil and heat resistance |

|

EPDM |

-40 °C to +140 °C |

Excellent resistance to water, steam, brake fluids, and UV |

Choosing the right oil seal KC begins with understanding the application’s requirements. Because this rotary shaft seal isn’t suitable for high pressure environments, it should only be used in pressureless systems, such as grease-lubricated housings or splash-lubricated enclosures. De shaft surface should have a hardness of at least 45 HRC to minimize wear, and the surface roughness should be between Ra 0.2 and 0.8 microns. The rotating shaft should meet ISO h11 tolerance and the housing should meet ISO H8 tolerance.

The operating temperature and chemical compatibility of the lubricant must be matched to the material of the seal. For example, synthetic greases of higher thermal loads may require a switch from NBR to FKM or ACM. If there’s exposure to ozone or weather, EPDM or CR are a suitable choice, while applications requiring long-term durability might benefit from HNBR. Silicone is best used in low-temperature or food-safe environments. When selecting a KC oil seal, consider shaft speed, rotational direction and any potential axial slack that could influence lip behaviour. Make sure that the housing and the rotating shaft are clean, dry and free from damage before installation. A press fit using appropriate tools will help avoid deformation of the rubber body.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The KC rotary shaft seal does not have a garter spring around the main sealing lip, unlike the TC type oil seal. This means it creates less friction but also cannot retain pressure. The oil seal KC is ideal for grease-filled, low-speed applications without internal pressure buildup.

Yes, if the oil is viscous enough and there is no pressure present in the system. For applications that use thin oils under pressure, spring-loaded seals like the TC rotary shaft seals are recommended.

Yes, as long as there is no pressure and the lubricant does not drain away downwards due to gravity. The right installation and lubrication of the lips is essential.

Make sure the shaft and the housing are clean and undamaged. Slightly lubricate both sealing lips and the space between with a suitable lubricant. Push the seal evenly in the housing without deforming the rubber outer shell. Do not hammer the seal directly.

Don’t use an oil seal KC in applications with internal pressure, high rotation speed or very thin lubricants. In such situations you should choose an oil seal with a spring-loaded main sealing lip and in some cases even a metal outer diameter. In some aggressive applications you should choose materials like FKM, AMC of EPDM. Which of them you should choose depends on the fluids and temperature.

Didn't find the right Oil Seal KC - Rotary Shaft Seal?

Complete the form below and we will help you!