| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

76546 | Oil Seal | 90 | 110 | 12 | NBR - Nitrile | Yes | No | Black | 8 | € 31,65 | Details | ||

|

76544 | Oil Seal | 295 | 335 | 16 | NBR - Nitrile | Yes | No | Black | 0 | € 372,62 | Details | Quote | |

|

73968 | Oil Seal | 212.74 | 264.6 | 15.87 | NBR - Nitrile | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

73827 | Oil Seal | 580 | 630 | 22 | NBR - Nitrile | Yes | No | Black | 1 |

Request

|

Details | Quote | |

|

71929 | Oil Seal | 640 | 690 | 22 | FPM - VITON | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

71909 | Oil Seal | 540 | 590 | 22 | FPM - VITON | Yes | No | Black | 0 |

Request

|

Details | Quote |

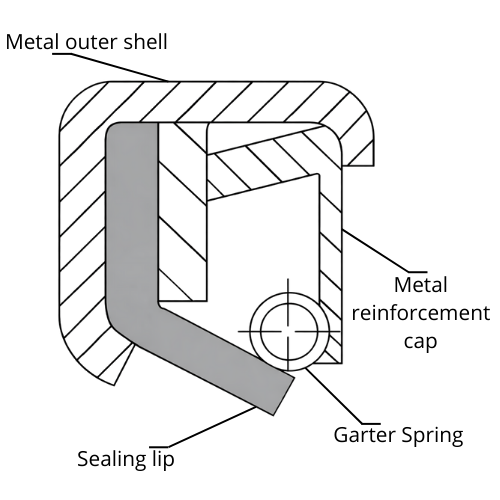

The W10 oil seal is distinguished by its specific and robust construction. The oil seal is designed with a metal outer diameter that is mounted precisely in the housing by means of a metal-to-metal press fit. This press fit ensures a very firm and accurate sealing, preventing rotation, tilting, or axial displacement of the oil seal under load. This helps to maintain a stable sealing performance, even at larger diameters and under varying operating conditions.

The sealing lip is made of elastomer and is pressed continuously and evenly against the rotating shaft by the integrated steel garter spring. This creates a constant sealing pressure throughout the entire service life of the oil seal, limiting wear and helping to prevent leakage. The sealing lip is not vulcanized but clamped between the housing plates.

This construction method makes the oil seal W10 shape-independent in production, allowing both large diameters and special dimensions to be realized without mold or tooling costs. This offers clear advantages in applications where standard DIN oil seals are not available, or where custom solutions are preferred from both an economic and technical perspective.

The W10 oil seal is mainly used in large machines and general machine engineering. Typical applications include industrial drives, gearboxes, pumps, heavy electric motors, and other rotating systems where reliability under varying loads is required. The pressure-loadable design makes the oil seal W10 suitable for applications where internal pressure may occur, up to approximately 0.5 MPa and, in specific versions, even up to 1 MPa.

In addition, the W10 rotary shaft seal is very suitable for large diameters, making it an attractive solution for heavy drives, process installations, and power generation equipment. The rigid press fit and robust construction ensure that the oil seal continues to function stably even under thermal load and during long-term operation.

The W10 oil seal is available in a variety of material combinations, made for the specific application. The standard oil seal W10 has a sealing lip that is made of NBR, an elastomer that offers excellent resistance to mineral oils and most common lubricants. NBR provides a favourable balance between wear resistance, elasticity, and cost and can be used within a temperature range of −40 °C up to +100 °C. NBR is less suitable for applications using higher temperatures or more aggressive media.

When higher thermal loads or synthetic lubricants are involved, FKM (Viton®) is often selected. This material is highly chemically stable and resistant to higher temperatures but is less flexible at low temperatures and generally more expensive than NBR.

For applications at very low temperatures, a silicone sealing lip can be used. Silicone retains its flexibility where other elastomers harden but has lower mechanical wear resistance and is less suitable for applications with higher pressure.

EPDM is used in specific situations where contact with aqueous fluids or glycol occurs. This material is not resistant to mineral oils and is therefore only applied in applications where oil resistance is not required.

For corrosive or aggressive environments, the housing and spring of the W10 oil seal can be made from stainless steel (AISI 316L), which ensures a reliable sealing performance even under such conditions.

|

Material |

Temperature range |

Key properties |

|

NBR (Nitrile Rubber) |

−40 °C to +100 °C |

Good resistance to mineral oils and greases, good wear resistance, cost-effective, limited resistance to high temperatures and aggressive chemicals |

|

FKM (Viton®) |

approx. −20 °C to +200 °C |

High temperature resistance, excellent chemical resistance, suitable for synthetic lubricants, lower flexibility at low temperatures, higher cost |

|

Silicone (VMQ) |

approx. −60 °C to +200 °C |

Excellent low-temperature flexibility, good thermal stability, low mechanical wear resistance, limited suitability for higher pressures |

|

EPDM |

approx. −40 °C to +120 °C |

Good resistance to water, steam and glycol, good aging resistance, not resistant to mineral oils, limited use in oil applications |

|

Stainless steel (AISI 316L) |

— |

Corrosion resistant, suitable for aggressive or humid environments, used for housing and spring in special executions |

The W10 oil seal can be compared to other radial shaft seals such as the SA oil seal and the PA31 oil seal, each designed for specific operating conditions and design requirements.

The SA oil seal is a metal-cased radial shaft seal with a spring-loaded elastomer sealing lip, primarily intended for standard sealing applications without significant internal pressure. While the basic sealing principle of the SA and W10 is similar, the W10 oil seal is specifically designed to be pressure-loadable and to offer a more robust seating in applications with higher mechanical loads or larger diameters. As a result, the W10 is typically selected where a standard SA seal reaches its functional limits.

When compared to the PA31 oil seal, the differences are mainly found in the sealing concept and operating focus. The PA31 uses a PTFE-based sealing lip and is intended for applications with higher circumferential speeds, reduced friction, or chemically demanding environments. The oil seal W10, by contrast, uses an elastomer sealing lip supported by a garter spring, making it a robust and cost-effective solution for pressure-loaded applications involving mineral or synthetic lubricants, where extreme speeds or aggressive chemicals are not the primary requirement.

Within this context, the W10 oil seal is positioned as a pressure-loadable, metal-cased sealing solution for industrial applications where mechanical robustness, dimensional stability, and reliable long-term performance are required.

When selecting the correct W10 oil seal, both the dimensions and the operating conditions play an important role. The dimensions are primarily based on the shaft diameter, the housing diameter, and the installation width. For correct operation, the shaft must meet ISO h11 tolerance, have a minimum hardness of 45 HRC, and feature a torsion-free surface. The recommended shaft surface roughness is between Ra 0.2 and 0.8 µm, with an Rz value of 1 to 5 µm, in order to prevent excessive wear of the sealing lip.

The housing must comply with ISO H8 tolerance and have a surface roughness between Ra 0.8 and 3.2 µm. Due to the metal-to-metal press fit, the W10 achieves a very firm seating; however, in light-metal housings, with increased surface roughness, or in applications involving overpressure, the use of a sealing compound on the outer diameter may be recommended.

In addition to dimensions, the operating parameters are equally important. For the standard material combination with an NBR sealing lip, the permissible temperature range is −40 °C to +100 °C, the maximum circumferential speed is 12 m/s, and the allowable pressure is up to 0.5 MPa, with optional versions up to 1 MPa. When synthetic lubricants or non-standard media are used, material compatibility must be carefully assessed, preferably through practical testing, whereby a continuous operating temperature of 80 °C must not be exceeded.

All parameters must always be considered in conjunction with one another. The final load on the seal is determined by the combination of temperature, pressure, speed, medium, and installation conditions. By carefully aligning these factors, the W10 oil seal can be used reliably and durably within its intended application range.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The W10 rotary shaft seal has a metal outer diameter and is pressure-loadable, whereas standard oil seals often have a rubber-coated outer diameter and are not intended for overpressure.

The oil seal W10 is suitable for pressures up to approximately 0.5 MPa and optionally up to 1 MPa, provided all operating parameters are correctly aligned.

Yes, the W10 oil seal is particularly suitable for large diameters and can be supplied with outer diameters of more than 1200 mm.

As standard, the oil seal W10 is supplied with an NBR sealing lip, an unalloyed steel housing, and an unalloyed spring steel spring. Special materials are available on request.

FKM (Viton®) is selected for higher temperatures, aggressive media, or synthetic lubricants where NBR does not provide sufficient service life.

Didn't find the right Oil Seal W10 - Rotary Shaft Seal?

Complete the form below and we will help you!