An axial seal (such as the axial seal AS-10 and axial seal AS-11) is a rotating axial sealing solution that is mainly used to keep external contamination out. Instead of sealing radially around the shaft like a classic oil seal, this type seals axially against an opposing face (the counterface). That is why axial seals are often used as a pre-seal in front of bearings and radial oil seals: they take care of the “dirty work” on the outside, so the actual sealing point and the bearing arrangement are less affected by mud, dust, splash water, or chips. The goal is therefore primarily protection and service life extension of the components behind it, not retaining pressure.

Within our range we offer two different axial seals: the AS-10 axial seal and the AS-11 axial seal. Both are intended as rotating axial protective seals against external contamination, but they differ in construction and in the level of protection you can achieve. Below we compare the AS-10 and AS-11, so you can quickly see which version best fits your conditions.

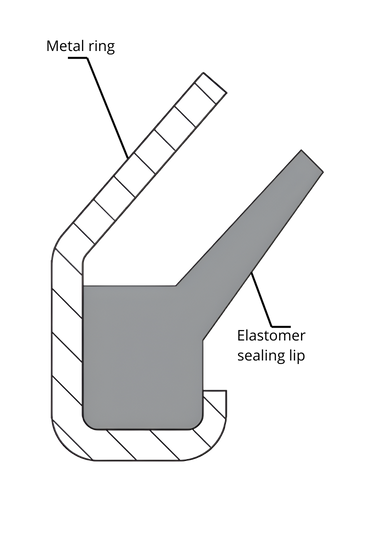

The axial seal AS-10 is the standard version: compact, easy to install, and intended as a general protective seal against contamination. From a design point of view it consists of a metal outer casing with an elastomer sealing element, where the metal ring rotates with the shaft and the elastomer provides the sealing contact against the counterface.

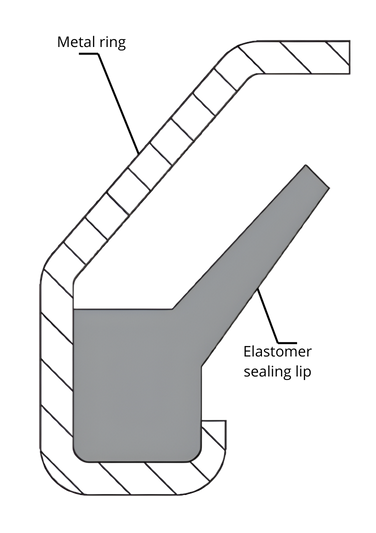

The axial seal AS-11 is similar in principle to the AS-10, but it is designed for situations where you want extra protection. The key difference is that the metal outer casing is axially extended at the outer diameter. If the counterface is made with a continuous groove, that extended ring creates an additional labyrinth effect. In practice this means more resistance against the ingress of contamination, especially when you are dealing with wet conditions, a lot of splash slurry, or abrasive particles that would otherwise migrate toward the sealing zone.

For the elastomer sealing element you typically choose between NBR and FKM. Which option is best, mainly depends on temperature, media, and environmental influences.

NBR is often the logical standard choice. It is widely applicable in systems with oils, greases, and commonly used hydraulic fluids. As a result, NBR is usually the most cost-effective option in practice. The limitation of NBR mainly shows up in situations with consistently higher temperatures or when weathering, ozone, and UV play a long-term role. For NBR, reference values are a temperature range of -40 °C to +100 °C, a speed up to 12 (20) m/s, and 0 MPa pressure. In terms of media, NBR is suitable, among other things, for vegetable and animal oils and fats, hydraulic oils (HL/HLP), mineral-based lubricating oils and greases, fire-resistant hydraulic fluids HFA/HFB/HFC, silicone oils, hot water up to approximately 80 °C, and aliphatic hydrocarbons.

You choose FKM when you need more margin in temperature and media. The material is often used at higher temperatures, with fuels, and with synthetic oils and greases, and it is generally more resistant to ozone, weathering, ageing, and UV. The trade-off is that FKM is more expensive and less flexible at low temperatures than NBR. For FKM, reference values are -30 °C to +180 °C, a speed up to 12 (20) m/s, and 0 MPa pressure. In terms of media, FKM is suitable, among other things, for mineral and synthetic oils and greases, HFD, fuels, aliphatic/aromatic/chlorinated hydrocarbons, non-polar solvents, and silicone oils/greases.

For both materials, it is important that the stated maxima are not intended to be run “at max” at the same time. In practice you choose a combination with margin, because temperature, speed, and media influence each other.

|

Material |

Temp range |

Key properties |

|

NBR |

-40 °C to +100 °C |

Standard choice for many oil, grease, and hydraulic applications; usually most cost-effective; less margin at higher temperature and under outdoor influences. |

|

FKM |

-30 °C to +180 °C |

Suitable at higher temperature, with fuels and synthetic oils; better resistance to ozone/weather/UV/ageing; more expensive and less flexible at low temperature. |

Axial seals are mainly used in situations where rotation goes hand in hand with contamination and where you want to keep the bearing location or a primary oil seal as clean as possible. Think of wheel hubs, (agricultural) machinery, pumps, drives and transmissions, but also general machine building where dust, moisture, or chips can easily build up around rotating parts. In such environments it is often not the primary oil seal that “fails,” but the conditions around it that accelerate wear: abrasive particles, a water film, mud, or chips reaching the sealing point.

The axial seal then sits as the first barrier on the outside. The metal ring is mechanically robust and protects the elastomer, while rotation helps to move contamination away from the sealing zone. You choose this type mainly when you want to increase reliability and service life without immediately having to move to larger and more complex sealing systems.

Axial seals are offered by multiple manufacturers and through various suppliers. In the market you will find both major sealing brands with industrial product lines and specialized seal suppliers and distributors that offer the axial seal AS-10/AS-11 as standard types. Naming can vary by brand, while the basic construction remains comparable. Use a cross reference mainly as a quick orientation, and when converting always check the datasheet for design, dimensions, material selection and, for the AS-11 axial seal, whether the labyrinth function is achieved with the correct counterface (groove).

|

Oil-Seal-Stocks (Design) |

Anyseals |

Simrit |

Trelleborg |

Forsheda / Stefa |

Dichtomatik |

Reina (Taiwan/China) |

|

AS-10 |

AS-10 |

MSC 01 |

TBP |

RB |

VRM01 |

RE |

|

AS-11 |

AS-11 |

MSC 02 |

TBR |

9RB |

VRM02 |

RE1 |

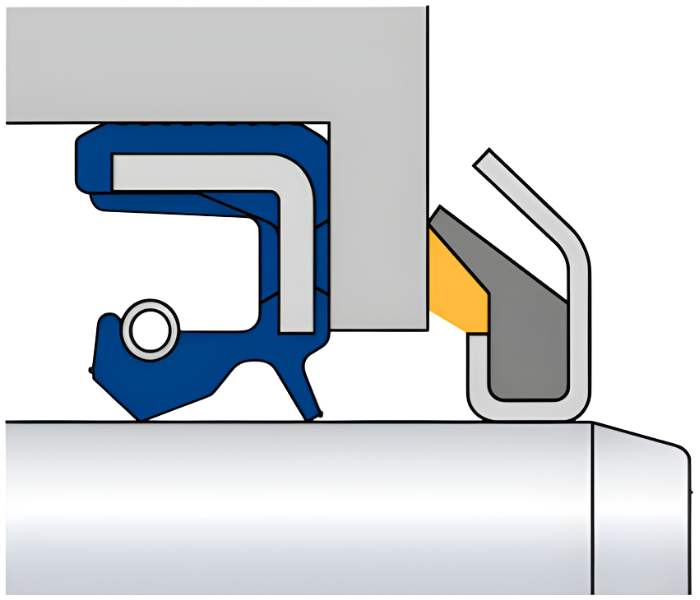

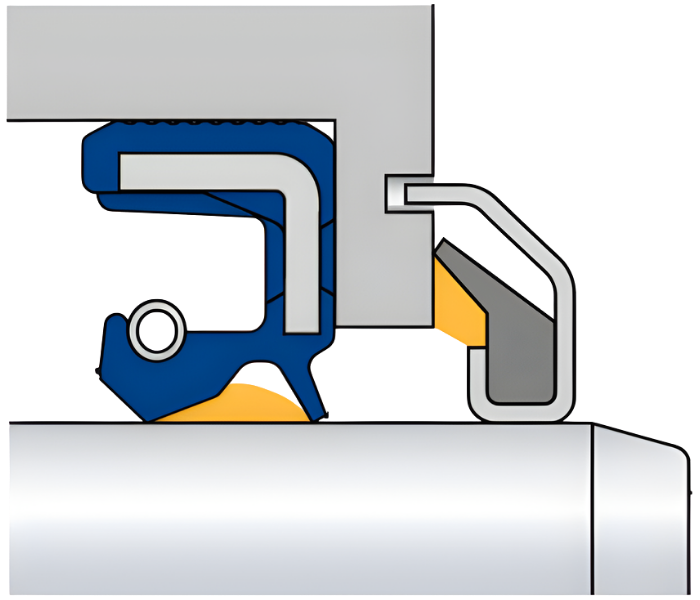

Start with the environment and the risk: if you mainly want to keep out general contamination, AS-10 axial seal is often the logical choice. If you operate consistently in wet, muddy, or abrasive conditions, or if you want extra security via a labyrinth barrier, you are more likely to choose AS-11 axial seal and design/check the counterface with the correct groove.

Next comes sizing. The shaft diameter determines the nominal size and how the ring is fixed on the shaft. In practice you want a stable fit that does not “walk” or creep, which is why you work with common ISO shaft tolerances that suit your design and installation method. The installation position is just as important: the seal must sit in the right place relative to the counterface so that the elastomer element makes correct contact.

The axial counterface is the next key point: it must be flat, clean, and sufficiently rigid to maintain consistent contact. For the axial seal AS-11, it is especially important that the groove/counterface design is correct if you want to use the labyrinth effect; otherwise, you may have the “long ring,” but not the extra barrier you expect.

Finally, choose the material based on the media and temperature. NBR is usually the standard for many oil/grease/hydraulic environments with a temperature range up to +100 °C, while FKM is a better fit if you move toward +180 °C or if fuels/synthetic oils play a role. Also follow the speed guideline (up to 12 (20) m/s) and remember that this type is intended for 0 MPa: it is a protective seal, not a pressure seal.

In conclusion, axial seals offer reliable protection and sealing in various applications. Their robust construction, use of high-quality materials, and effective design ensure their performance in demanding operating conditions. Whether it's preventing contaminants in mechanical systems or safeguarding sensitive components in electric motors, axial seals are an essential component for maintaining equipment integrity and longevity. Choose axial seals for your sealing needs and experience their proven reliability and functionality.

If you want more information about Axial seals, feel free tot contact us.

Maybe interested in our high-quality Freudenberg Axial Seals? Take a look at our Freudenberg Sealing Technologies website!

No. An oil seal typically seals radially around the shaft to keep oil or grease in. An axial seal seals axially against a face and is mainly used to keep external contamination out.

No, this type is intended for applications without relevant pressure (0 MPa). Its function is protection against dirt and moisture.

When you want extra protection via a labyrinth effect, for example with mud, splash water, or abrasive contamination, and you can design the counterface (with groove) accordingly.

Choose NBR as the standard for many oil/grease/hydraulic applications and normal temperatures. Choose FKM if you expect higher temperatures, fuels, synthetic oils, or more severe outdoor influences.

Usually at the counterface and positioning: if the counterface is not flat or not clean, or if the seal does not run in the correct position relative to the counterface, you are more likely to get wear or insufficient shielding. With axial seal AS-11, the correct groove/counterface design is also decisive for the labyrinth function.