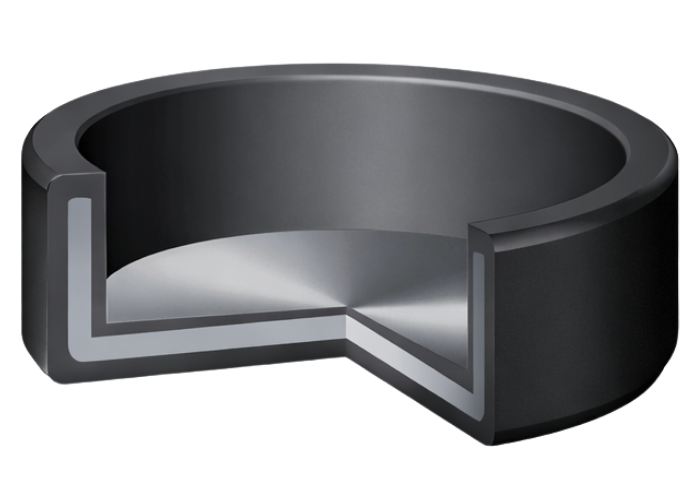

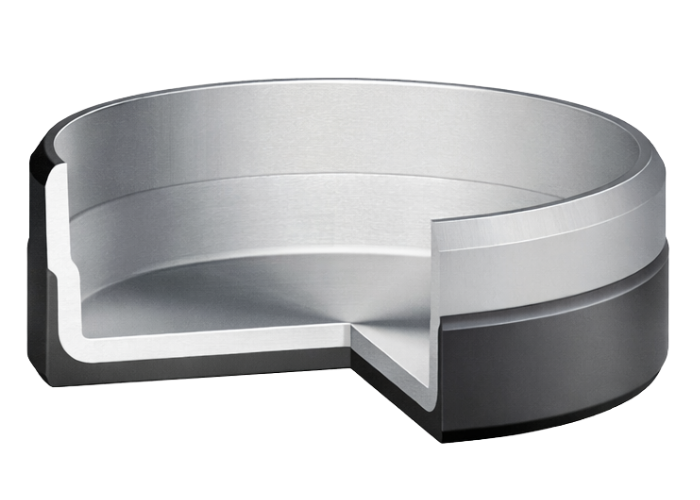

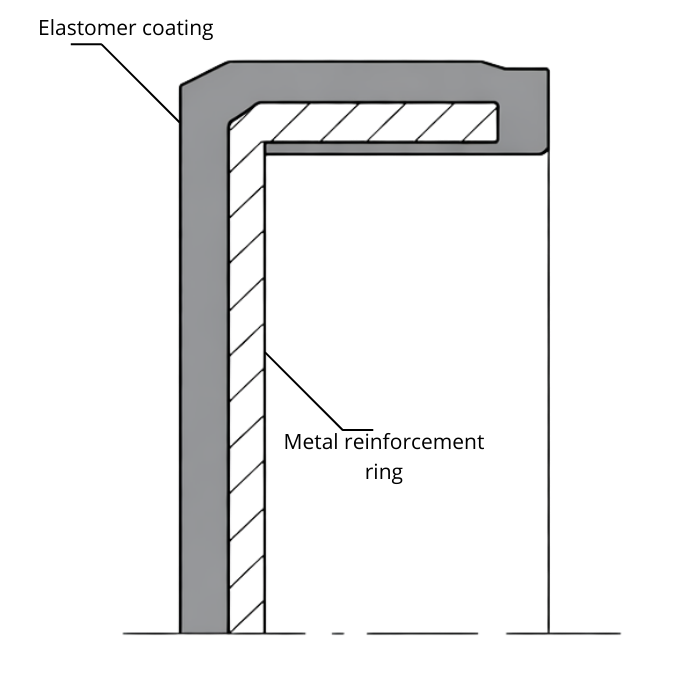

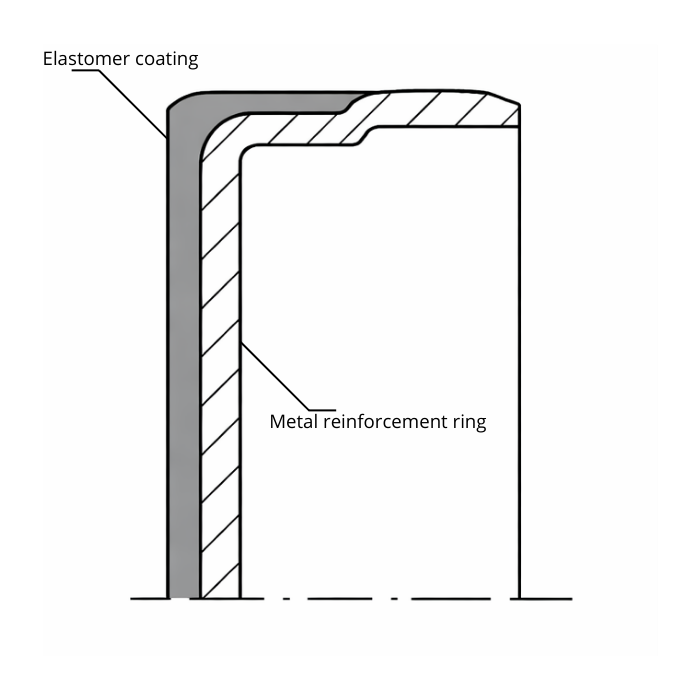

End caps are static seals used to permanently or temporarily “blind” a bore or shaft feedthrough when there is no rotating shaft running through it. Instead of a sealing lip that runs on a shaft, end caps close off the opening itself: they keep oil or grease inside while keeping dust, moisture and splash water out. They are generally made up of a steel stiffening ring with a vulcanised elastomer outer casing, giving you a rigid core for a reliable press fit and a rubber outer surface that provides the static seal against the bore wall.

Both CS-10 and CS-12 work according to the same principle (a press-fit end cap with a steel ring and an elastomer outer surface), but the difference is mainly in the outer casing and therefore the installation behaviour. In the market, CS-10 is generally used for the version with a smooth elastomer outer casing: it provides a very stable static seal in standard housings and is straightforward to install with the correct press fit. CS-12 is the version with a grooved/ribbed structure in the elastomer outer casing; it is intended to make installation easier and is particularly interesting in housings with relatively high thermal expansion (for example certain light metal housings), because the grooves provide a bit more compliance during installation and operation. In NBR, suppliers for this type often specify a temperature range of around -30 to +100 °C, and it remains a solution for (virtually) non-pressurised applications.

Material selection mainly depends on temperature, media and ageing. NBR (nitrile) is the standard: it performs well in mineral oils and greases and is therefore a logical choice for gearboxes, bearing housings and transmissions. The downside is that NBR is limited at higher temperatures and ages faster in certain chemical environments. FKM (Viton/FPM) is chosen when temperature and chemical exposure become more demanding: it typically handles higher temperatures, is more resistant to many oils (including synthetic) and fuels, and offers excellent resistance to ageing and ozone, at the cost of higher price and less flexibility at low temperatures. In many end-cap families, you’ll see NBR around 70 Shore A and FKM around 80 Shore A, with temperature ranges that in practice are often stated as -30 to +100 °C (NBR) and -20 to +200 °C (FKM).

|

Material |

Temperature (indicative) |

Advantages |

Considerations |

|

NBR |

-30 to +100 °C |

Strong in mineral oil/grease, good price-performance |

More limited at high temperature/ozone and some chemicals |

|

FKM (FPM/Viton) |

-20 to +200 °C |

Stronger in heat and chemicals, good ageing and ozone resistance |

More expensive, less suitable for very low temperatures |

You use an end cap whenever you want to close off a bore or shaft feedthrough in a housing without a moving seal. Think of transmissions and gearboxes where a (spare) opening is present, bearing blocks where you want to seal one side, split housings where you need a compact end seal, or light metal housings where a press-fit solution is practical. End caps are also used with thin-flowing or even gaseous media, provided the application is not intended as a “true pressure seal”. In many designs they are also a practical alternative to sealing flanges or screw-on covers: fewer components, less machining and fast installation using the same bore logic as a radial shaft seal.

With end caps you broadly see two worlds: manufacturers who develop families and profile variants, and suppliers/distributors who keep a wide size range in stock. Freudenberg Sealing Technologies (and the standard line Dichtomatik) is a well-known source for end-cap profiles with variants such as smooth and grooved outer casings. Trelleborg also offers end covers as rubber-coated metal caps that are often used as an alternative to flanges/covers in gearbox applications. In bearing and unit environments you also come across SKF end covers (more as protection/covering on bearing units). On the supply side you’ll find parties such as ERIKS (with EC types), Kimman Seals (end covers in multiple versions) and specialised webshops that supply by series and size, including Oil-Seal-Stocks itself.

Always start with the bore size: the outer diameter of the end cap must match the housing bore and is usually selected using the same logic/tolerances as the outer diameter of an oil seal. Next you determine the height (thickness) so the cap sits correctly in the available installation space and does not end up “preloaded”. Then you choose the material based on media and temperature: NBR for standard oil/grease and normal temperatures, FKM if you move towards higher temperatures, synthetic oils/ATF or more aggressive media. After that you choose the profile type: a smooth outer casing (CS-10) is often ideal for “normal” housings and a predictable press fit; a grooved outer casing (CS-12) can be the smarter choice when installation ease and thermal expansion of the housing are more important. For reliable installation, a hydraulic or mechanical press-in tool is recommended, with the force acting as much as possible on the outer diameter; in addition, bore guidelines are often referenced in accordance with DIN 3760 and an H8 tolerance zone according to DIN ISO 286. If higher pressure does come into play, extra mechanical retention (such as a retaining ring/circlip) may be necessary, but fundamentally this remains a solution for (virtually) non-pressurised applications.

In summary, end caps offer a reliable and secure closure solution for bores, bearings, and shaft feedthroughs. With their use of high-quality materials, wide temperature range, and versatile design options, end caps provide effective sealing in various industries and applications. By choosing end caps, you can ensure a tight seal, prevent leaks, and protect critical components, ultimately enhancing the performance and longevity of your equipment.

If you would like more information about End Caps, feel free to contact us.

Maybe interested in our high-quality Freudenberg End Caps? Take a look at our Freudenberg Sealing Technologies website!

No: an oil seal seals dynamically on a rotating shaft, while an end cap statically closes an opening where no shaft runs through. The installation (press-fit in a bore) can sometimes resemble that of an oil seal, but the function is different.

In practice, end caps are mainly used in non-pressurised or low-pressure applications; many product families communicate limits around approximately 0.5 bar and emphasise that it is a static closure. For (structurally) higher pressure, a different design is usually required, or at least additional retention.

Choose NBR if you mainly work with mineral oil and grease within normal temperatures and want a strong, economical solution. Choose FKM if temperature and chemical exposure are higher or if you need additional ageing and ozone resistance.

CS-10 is the “smooth” press-fit version for a stable standard press fit; CS-12 has a grooved/ribbed outer casing that can make installation easier and is more often chosen for housings with relatively high thermal expansion.

Make sure the bore size and tolerances are correct, choose the right OD/height, and press the end cap in straight using a tool that supports the outer diameter. Guidelines often refer to DIN 3760 and H8 tolerances for the bore; misalignment and “spring-back” during pressing are typical causes of problems.