| Product | Product Id | Type | Outer Diameter | Height | Material | Housing Material | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

25606 | End Cap | 150 | 13 | NBR - Nitrile | Steel | Black | 96 | € 12,82 | Details | |

|

25607 | End Cap | 210 | 15 | NBR - Nitrile | Steel | Black | 12 | € 20,10 | Details | |

|

25608 | End Cap | 47 | 10 | NBR - Nitrile | Steel | Black | 27684 | € 2,52 | Details | |

|

25609 | End Cap | 52 | 10 | NBR - Nitrile | Steel | Black | 23810 | € 2,86 | Details | |

|

25610 | End Cap | 72 | 9 | NBR - Nitrile | Steel | Black | 3661 | € 4,23 | Details | |

|

25611 | End Cap | 35 | 8 | NBR - Nitrile | Steel | Black | 2642 | € 1,78 | Details | |

|

25612 | End Cap | 80 | 12 | NBR - Nitrile | Steel | Black | 5645 | € 5,28 | Details | |

|

25613 | End Cap | 90 | 12 | NBR - Nitrile | Steel | Black | 6 | € 6,85 | Details | |

|

25614 | End Cap | 40 | 7 | NBR - Nitrile | Steel | Black | 5263 | € 2,03 | Details | |

|

25615 | End Cap | 75 | 12 | NBR - Nitrile | Steel | Black | 2669 | € 4,46 | Details | |

|

25616 | End Cap | 55 | 10 | NBR - Nitrile | Steel | Black | 3866 | € 2,86 | Details | |

|

25617 | End Cap | 62 | 8 | NBR - Nitrile | Steel | Black | 6162 | € 3,69 | Details | |

|

25618 | End Cap | 30 | 7 | NBR - Nitrile | Steel | Black | 9249 | € 1,64 | Details | |

|

25619 | End Cap | 14 | 3 | NBR - Nitrile | Steel | Black | 73 | € 1,31 | Details | |

|

25620 | End Cap | 47 | 4 | NBR - Nitrile | Steel | Black | 1495 | € 1,80 | Details | |

|

25621 | End Cap | 39 | 4 | NBR - Nitrile | Steel | Black | 1732 | € 2,89 | Details | |

|

25622 | End Cap | 26 | 4 | NBR - Nitrile | Steel | Black | 4716 | € 1,67 | Details | |

|

25623 | End Cap | 32 | 9.5 | NBR - Nitrile | Steel | Black | 12508 | € 1,78 | Details | |

|

25624 | End Cap | 28 | 7 | NBR - Nitrile | Steel | Black | 7114 | € 1,67 | Details | |

|

25625 | End Cap | 22 | 7 | NBR - Nitrile | Steel | Black | 88 | € 1,46 | Details | |

|

25626 | End Cap | 26 | 6.5 | NBR - Nitrile | Steel | Black | 5639 | € 1,67 | Details | |

|

25627 | End Cap | 30 | 8 | NBR - Nitrile | Steel | Black | 1304 | € 1,67 | Details | |

|

25628 | End Cap | 37 | 10 | NBR - Nitrile | Steel | Black | 1778 | € 2,03 | Details | |

|

25629 | End Cap | 42 | 9.5 | NBR - Nitrile | Steel | Black | 3130 | € 2,06 | Details | |

|

25630 | End Cap | 47 | 6.5 | NBR - Nitrile | Steel | Black | 260 | € 2,52 | Details | |

|

25631 | End Cap | 52 | 6.5 | NBR - Nitrile | Steel | Black | 2017 | € 2,86 | Details | |

|

25632 | End Cap | 68 | 8 | NBR - Nitrile | Steel | Black | 60 | € 4,36 | Details | |

|

25633 | End Cap | 75 | 7 | NBR - Nitrile | Steel | Black | 940 | € 4,20 | Details | |

|

25634 | End Cap | 85 | 12 | NBR - Nitrile | Steel | Black | 1289 | € 6,24 | Details | |

|

25635 | End Cap | 90 | 8 | NBR - Nitrile | Steel | Black | 5 | € 6,85 | Details |

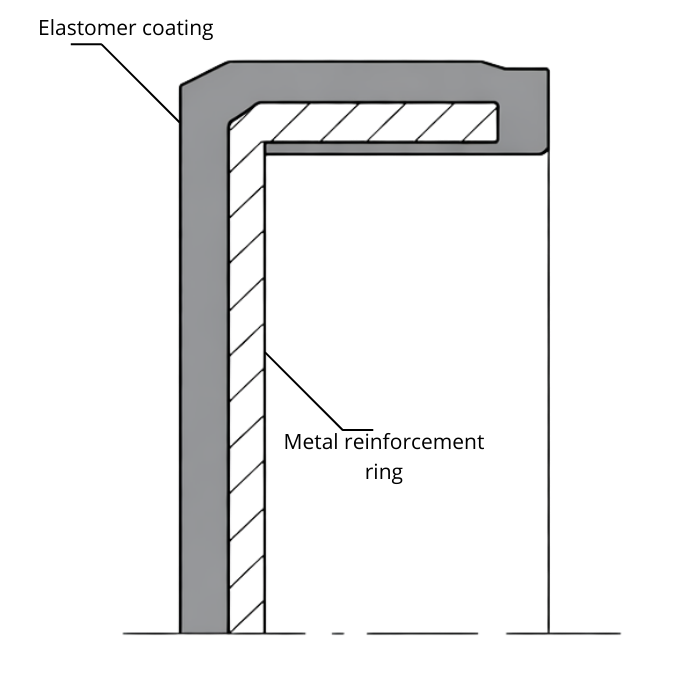

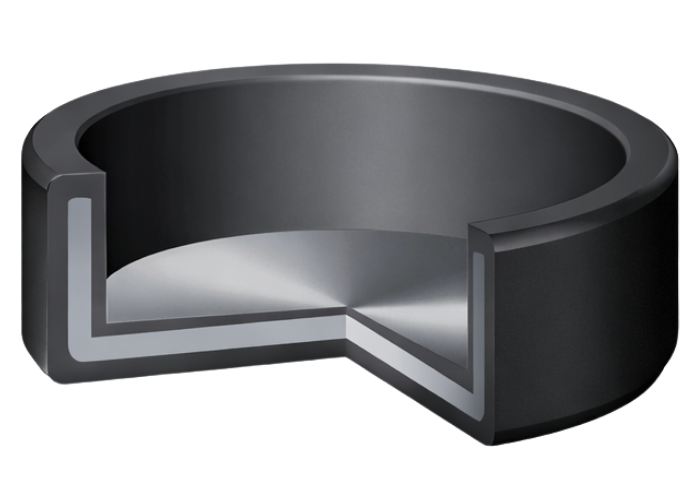

The CS-10 end cap consists of a steel reinforcement ring that is fully covered with a vulcanised elastomer outer jacket. The steel core ensures dimensional stability and mechanical strength during installation and operation, particularly with the required press fit in the bore. As a result, the end cap retains its geometry even under thermal loads or vibrations.

The elastomer outer jacket provides the actual sealing against the bore wall. Thanks to the rubber layer, the end cap CS-10 can compensate for small deviations in roundness, surface finish, and dimensional tolerances, creating a reliable static seal. The seal contains no spring, lip, or moving parts, which eliminates wear and contributes to a long service life.

CS-10 end caps are widely used in bearing housings, gearboxes, transmissions, motor reducers, and pump housings. They are ideal for sealing unused shaft openings or inspection bores. In bearing blocks, for example, they are used to completely close the side without a shaft, keeping grease inside and contamination out.

The end cap CS-10 is particularly suitable for these applications because it provides a fully closed seal without complex installation or additional components. The combination of a rigid metal core and a flexible sealing layer makes the end cap resistant to vibrations and slight thermal expansion, while remaining leak-free at low or no pressure. This makes the CS-10 type a logical alternative to cover plates or flanges in compact designs.

The CS-10 end cap is available with different elastomer qualities, selected according to temperature, media, and environmental conditions.

NBR is the standard material for most applications. It offers good resistance to mineral oils and greases and has a favourable temperature range for general industrial environments. NBR is flexible, wear-resistant, and cost-efficient. A limitation is its reduced resistance to high temperatures, ozone, and aggressive chemicals.

FKM is used when higher temperatures, synthetic oils, fuels, or chemical media are involved. This material provides excellent thermal and chemical resistance and shows minimal ageing. A disadvantage of FKM is its reduced flexibility at low temperatures and its generally higher cost.

The choice between NBR and FKM is determined by the operating temperature, the medium to be sealed, and the desired service life of the seal.

|

Material |

Temperature range (indicative) |

Key properties |

|

NBR (Nitrile rubber) |

approx. −30 °C to +100 °C |

Good resistance to mineral oils and greases, flexible, wear-resistant, and cost-efficient. Suitable for general industrial applications. Less suitable for high temperatures, ozone exposure, and aggressive chemicals. |

|

FKM (Fluoro rubber) |

approx. −20 °C to +200 °C |

Excellent resistance to high temperatures, synthetic oils, fuels, and chemicals. Very good ageing and ozone resistance. Less flexible at low temperatures and higher cost than NBR. |

When selecting the correct CS-10 end cap, bore diameter, installation depth, and material choice are decisive. The outer diameter of the end cap must exactly match the bore into which it is press-fitted. For a reliable press fit, a bore with ISO tolerance H8 is recommended.

The height of the end cap must fit within the available installation space and provide sufficient axial support. Many CS-10 end caps are dimensionally aligned with standard oil seal sizes, allowing easy use in existing designs.

In addition, the selected elastomer must be suitable for the temperature, the medium, and the environmental conditions. Since the end cap CS-10 is a static seal, it is not suitable for applications involving rotation or pressure build-up; this should be taken into account during the design phase.

|

Anyseals |

Simrit (Freudenberg) |

Trelleborg |

Forsheda / Stefa |

Dichtomatik |

Taiwan / China |

|

CS-10 |

GA |

YJ38 |

VK |

VER |

EC |

In summary, the CS-10 End Cap is a reliable sealing solution that provides secure closure and effective sealing for bores, bearings, and shaft feedthroughs. Its utilization of highly resistant materials, wide temperature range, and customizable design options make it an ideal choice for various applications. Whether it's sealing transmissions, bearing blocks, split housings, or light metal housings, the CS-10 ensures reliable performance and protects against leaks and contamination. Trust in the CS-10 End Cap for secure closure and superior sealing performance in your applications.

I you want more information or do you have any questions about the CS-10? feel free to contact us.

A CS-10 end cap completely closes a bore without a shaft passage and is static. An oil seal provides dynamic sealing around a rotating shaft.

No, the end cap CS-10 is intended for static sealing at low or no pressure.

No, due to the press fit the end cap may deform during removal. Reuse is not recommended.

A bore with ISO tolerance H8 is recommended for reliable sealing.

For higher temperatures and aggressive media, FKM is the best choice.

Didn't find the right End Cap CS-10?

Complete the form below and we will help you!