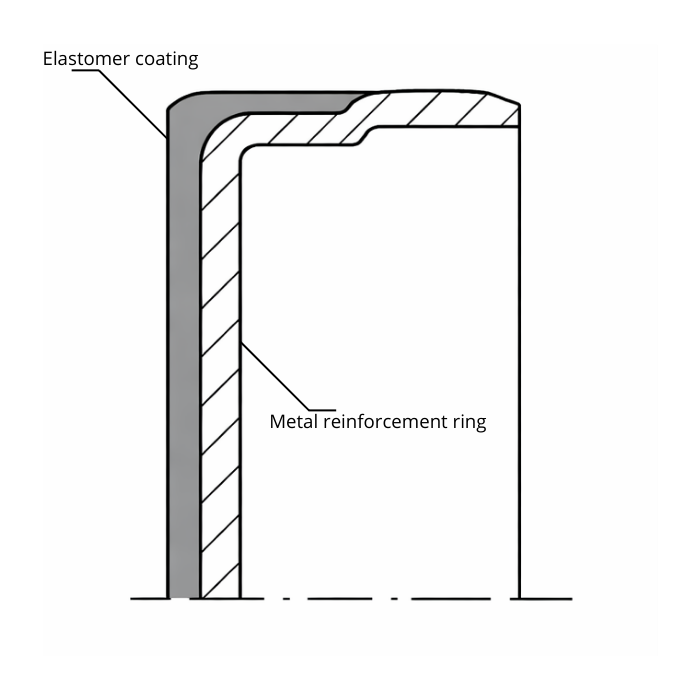

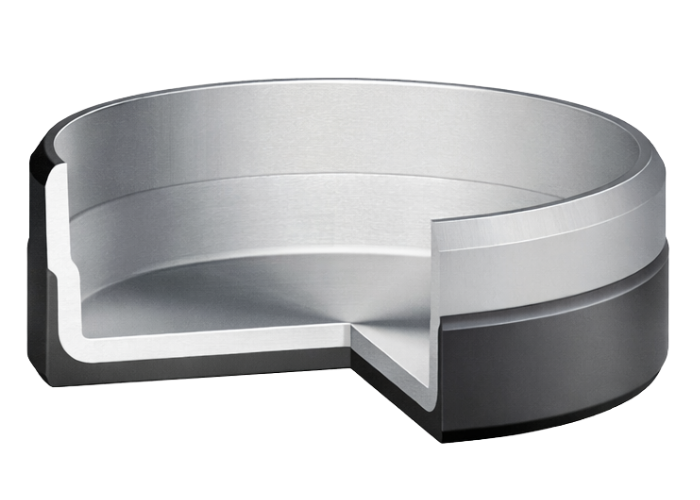

The End Cap CS-12 consists of a steel reinforcement ring that is fully covered with a vulcanised elastomer outer layer. The steel core ensures dimensional stability and prevents deformation during installation and operation, particularly under the required press fit. This keeps the end cap mechanically stable, even under thermal load.

The elastomer outer layer provides the static seal against the bore wall and can compensate for small deviations in dimensions, roundness and surface finish. This makes the CS-12 End Cap suitable for both precision-machined and cast or split housings. The design is intended for axial installation and contains no moving parts, sealing lips or springs. As a result, the end cap is low-wear and designed for long-term, maintenance-free static sealing.

The End Cap CS-12 is used in a wide range of industrial environments, including gearboxes, gear motors, bearing housings and split housings. In these applications, bores are often required for assembly but must be completely sealed during operation. The CS-12 End Cap is suitable for this purpose because it requires minimal installation space, and it provides a durable seal without additional fastening elements. Thanks to the combination of rigidity and elastic sealing, the end cap can also be used in environments where light vibrations or temperature changes are present.

The End Cap CS-12 is available in different elastomer compounds, with NBR and FKM being the most used.

NBR is suitable for general industrial applications and offers good resistance to mineral oils and greases. The material performs reliably within a temperature range of approximately −30 °C to +100 °C and is economically attractive. Limitations of NBR occur at higher temperatures and when exposed to ozone or aggressive chemicals.

FKM is selected when the application requires higher temperature and chemical resistance. This material remains stable up to approximately +200 °C and is resistant to synthetic oils, fuels and various chemicals. FKM offers a longer service life under demanding conditions but has a higher cost and reduced flexibility at low temperatures.

|

Material |

Temperature range (indicative) |

Key properties |

|

NBR (Nitrile rubber) |

approx. −30 °C to +100 °C |

Good resistance to mineral oils and greases, elastic, cost-effective and suitable for general industrial applications. Less suitable at high temperatures, ozone exposure and aggressive chemicals. |

|

FKM (Fluoro rubber) |

approx. −20 °C to +200 °C |

Excellent chemical resistance, high temperature resistance, good ageing and ozone resistance. Suitable for demanding conditions, but higher cost and less flexible at low temperatures. |

When selecting an End Cap CS-12, both dimensions and material choice play an important role. The outer diameter of the end cap has to match the bore diameter, which typically is based on a housing tolerance according to ISO H8. This ensures sufficient press fit and prevents the end cap from becoming loose during operation. The height of the end cap must be matched to the bore depth to allow correct positioning without inducing stress in the material.

When choosing the right material you should keep an eye on operating conditions such as temperature, type of medium and environmental influences. For standard oil or grease applications, NBR is usually enough, while FKM is recommended for higher temperatures or chemical exposure. Careful axial installation using the right tools is essential in order to prevent damage to the elastomer layer.

In summary, the CS-12 End Cap is a reliable sealing solution that provides secure closure and effective sealing for bores, bearings, and shaft feedthroughs. Its utilization of highly resistant materials, wide temperature range, and customizable design options make it an ideal choice for various applications. Whether it's sealing transmissions, bearing blocks, split housings, or light metal housings, the CS-12 ensures reliable performance and protects against leaks and contamination. Trust in the CS-12 End Cap for secure closure and superior sealing performance in your applications.

I you want more information on the CS-12 end cap or do you have any questions about the CS-12 end cap? feel free to contact us.

An oil seal is intended for dynamic sealing around a rotating shaft, whereas an end cap fully closes a bore without a shaft.

The CS-12 is suitable for static sealing at low or no pressure and is not designed for high-pressure applications.

Typically, a bore with ISO H8 tolerance is used to ensure a reliable press fit.

At higher temperatures, with chemically aggressive media, or in applications with increased service life requirements.

Didn't find the right End Cap CS-12?

Complete the form below and we will help you!