Garlock PS-SEAL® is a high-performance radial shaft seal for rotating shafts, built around a PTFE (GYLON® / modified PTFE) sealing lip in a stainless-steel housing. You typically choose it when a “standard” elastomer oil seal (NBR/FKM) does not have enough margin at higher pressure, higher circumferential speeds, aggressive or abrasive media, or extreme temperatures. In practice, PS-SEALs are not only used as primary shaft seals, but also applied as an alternative to mechanical seals and braided packing (packing) when you want a simpler design without compromising operational reliability. The core of that performance lies in the lip materials: Garlock produces GYLON itself as a high-performance PTFE material with strong sealing properties.

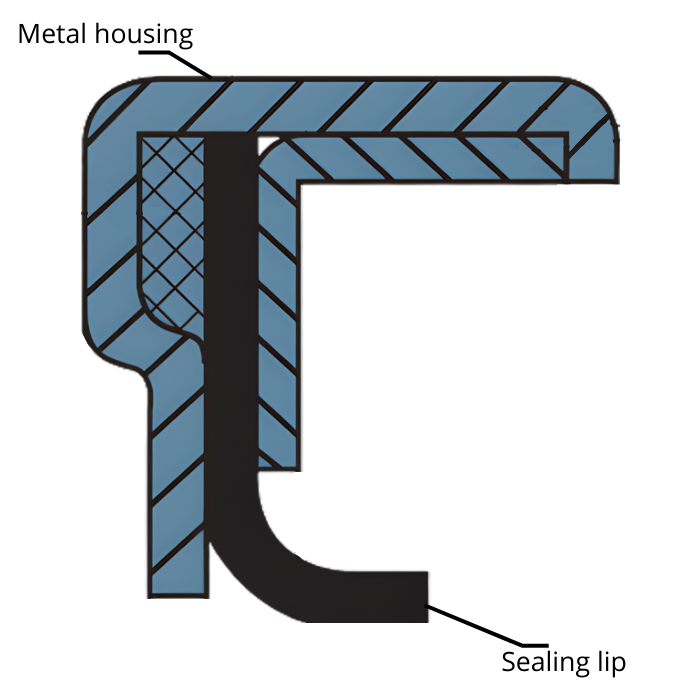

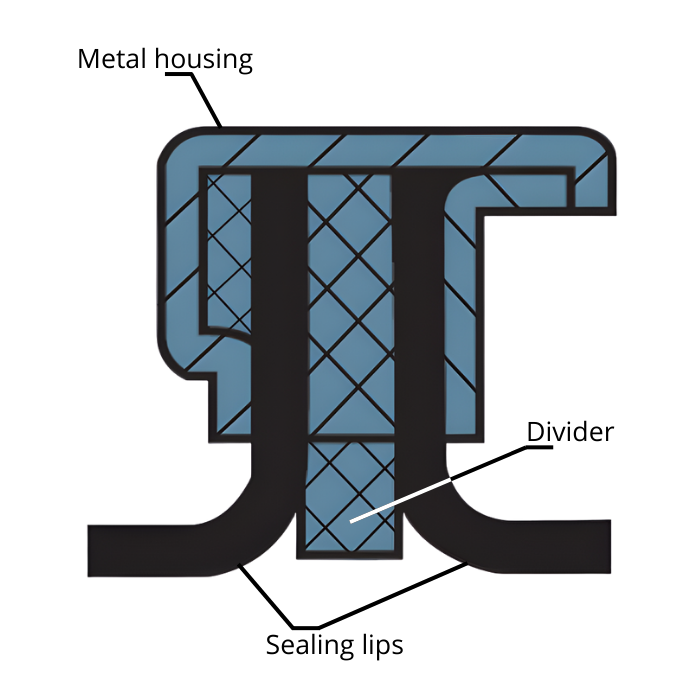

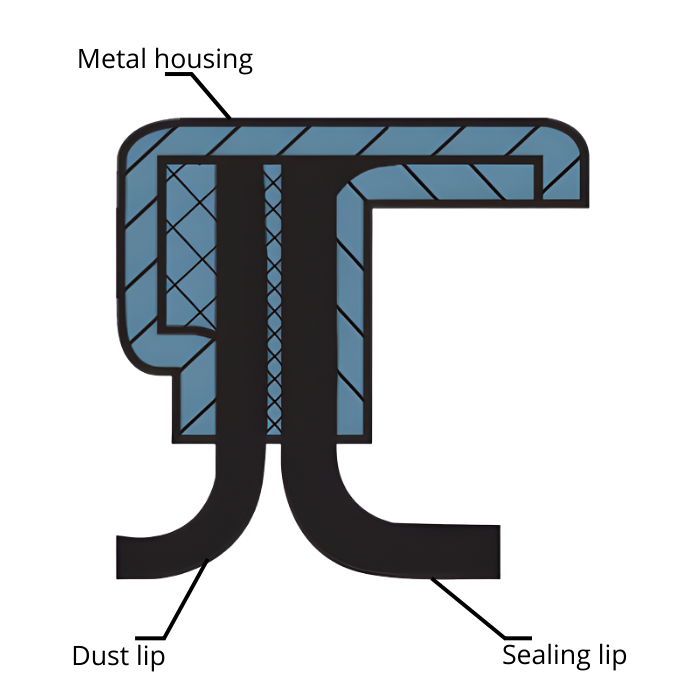

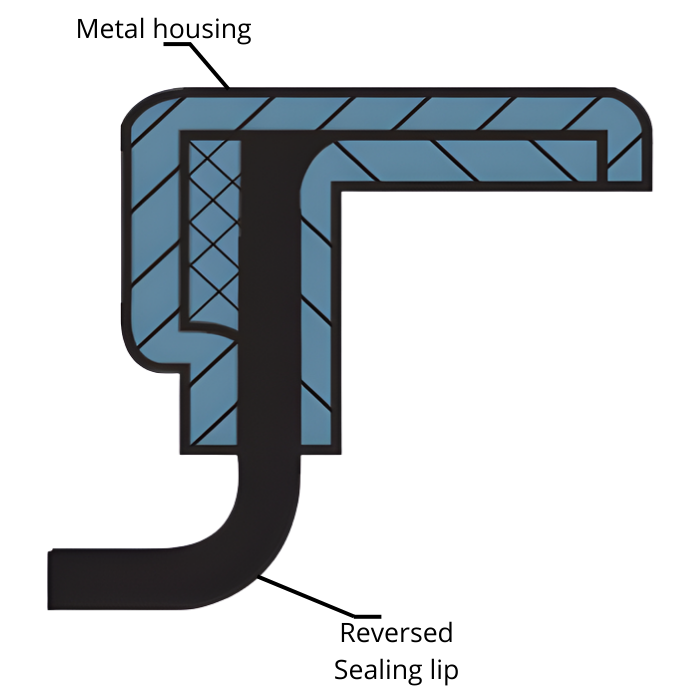

The PS-SEAL® Standard is the base configuration with a single lip and is usually selected for heavy-duty, primarily lubricated applications where you want to gain service life and reliability compared with a classic NBR/FKM oil seal. The PS-SEAL Back-to-Back combines two lips facing opposite directions, allowing you to seal to both sides within one compact unit; this is useful when you want to keep both the process side and the outside side “under control.” The tandem PS-SEAL uses two lips facing the same direction (toward the medium) and thereby builds an additional sealing stage, giving you extra margin when leakage toward the medium can quickly lead to downtime or product loss. The PS-SEAL reverse turns the lip direction around compared to the standard orientation and is chosen when the effective pressure side, the installation situation, or the design calls for sealing in the other direction. The dustlip PS-SEAL adds an extra protective lip on the outside that mainly acts as a barrier against dirt, dust, and splash water, so the main sealing lip “sees” less contamination and typically remains stable for longer in dirty environments.

A PS-SEAL’s performance is largely determined by the lip compound: modified PTFE provides low friction, broad chemical resistance, and high temperature resistance, while fillers tune the seal for lubrication, dry running, abrasion, or food/pharma compliance. In general: graphite-filled PTFE is a strong all-round choice for lubricated service; FDA-focused compounds emphasize hygiene and media compatibility; and “dry running” compounds are chosen when lubrication cannot be guaranteed, but they do require a correct counterface and good shaft conditions. In the food and pharma space, it is relevant that PS-SEALs can also be supplied in an FDA-compliant execution (depending on material selection).

|

Material |

Temperature range (guideline) |

Key properties (incl. trade-offs) |

|

GYLON® Black (PTFE/graphite) |

approx. –90 to +260 °C |

Strong for lubricated service, stable wear, low friction; not the first choice for prolonged dry running. |

|

GYLON® White (PTFE + barium sulfate) |

approx. –90 to +260 °C |

Often chosen for food/pharma (FDA-focused); good sealing tightness; at higher speeds friction heat can become limiting if lubrication is marginal. |

|

GYLON® Blue (PTFE + glass microspheres) |

approx. –90 to +260 °C |

Very suitable for dry running and situations with low shaft roundness; less ideal in highly abrasive media. |

|

GYLON® Brown-White (two-sided) |

approx. –90 to +260 °C |

Aimed at abrasive food applications: wear resistance + thermal management; useful when product wear and cleanability interact. |

|

F (PTFE “Econol”) |

approx. –90 to +260 °C |

Ideal for higher speeds where gas tightness and dry-running capability are important; works best when shaft concentricity and counterface quality are tight. |

|

MS (molybdenum disulfide) |

approx. –90 to +260 °C |

Good for abrasive dust/powders and dry running; wear-resistant with stable behavior under load. |

|

KF (carbon fiber) |

approx. –90 to +260 °C |

Suitable for (partly) abrasive media and dry running; added mechanical stability due to fiber reinforcement. |

|

FKM (static sealing element in many versions) |

typically up to ~200 °C (build-dependent) |

Practical static sealing element; can be the temperature-limiting component compared with the PTFE lip. |

PS-SEALs are often used on rotating equipment where reliability matters and where standard lip seals struggle: higher speeds, elevated pressure, aggressive chemicals, abrasive product, or large temperature fluctuations. You see them in pumps, mixers/agitators, gearboxes, screw conveyors, and similar machines, especially when you want to stop recurring leakage and extend maintenance intervals. In demanding conditions, the combination of vacuum resistance and high-pressure resistance is also a reason to consider PS-SEALs, particularly when you want to achieve stable sealing with one compact unit.

Start with the correct size (shaft diameter, housing bore, width), then choose the lip configuration based on the problem you want to solve: Dustlip for dirty environments, Tandem for extra sealing margin toward the medium, Back-to-Back if you want sealing to both sides, and Reverse when the effective pressure side or the design calls for the reversed orientation. Next, match the lip material to lubrication (lubricated vs dry), medium (chemical compatibility, FDA/food/pharma), and wear risk (abrasives), and always check the operating window: pressure, circumferential speed, and temperature, because friction heat and p×v loading can be the real limiter. For a good result, the counterface is part of the seal: the right roughness, hardness, and “no helical machining marks” often make the difference between long service life and early leakage.

In summary, Garlock PS-Seals are renowned for their reliability and durability in challenging operating conditions. With a wide range of material options, including the high-performance Gylon, these seals provide effective sealing solutions for various industries. Their temperature resistance, vacuum and high-pressure resistance, and excellent chemical resistance make them a trusted choice for demanding applications. Whether used as standard seals or customized for specific requirements, Garlock PS-Seals deliver optimal performance, ensuring secure and efficient sealing for rotating shafts.

If you would like more information about PS-Seal or if you do not know which PS-Seal you should have, please feel free to contact us.

Yes, especially when pressure, speed, temperature, or medium fall outside the reliable range of elastomer lips.

Back-to-Back is for sealing to both sides; Tandem is for additional sealing stages in the same direction toward the medium.

In many applications it can, especially if you want a more compact and simpler solution with high operational reliability.

Yes, vacuum resistance is one of the reasons to consider PS-SEALs in challenging process conditions.