A V-ring is a fully elastomeric, rotating shaft seal that you slide over the shaft. Instead of sealing radially around the shaft like a classic oil seal, the flexible V-lip runs axially against a fixed counterface (for example a bearing cover, flange, or retaining washer). This creates a clear protective barrier: it keeps dirt, dust, mud, and splash water out, while also shielding the transition between the shaft and the housing. In addition, a V-ring helps retain grease (and a light lubricant film) to a limited extent, which can reduce wear on the bearing arrangement and on downstream seals. Because the lip contact pressure is low, friction remains limited and installation is easy: the elasticity of the rubber makes it a practical and cost-effective solution for many rotating shafts.

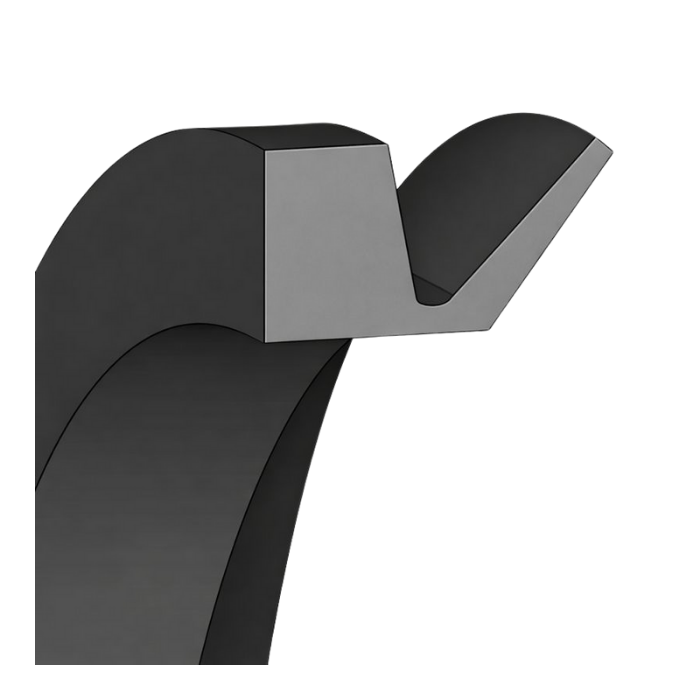

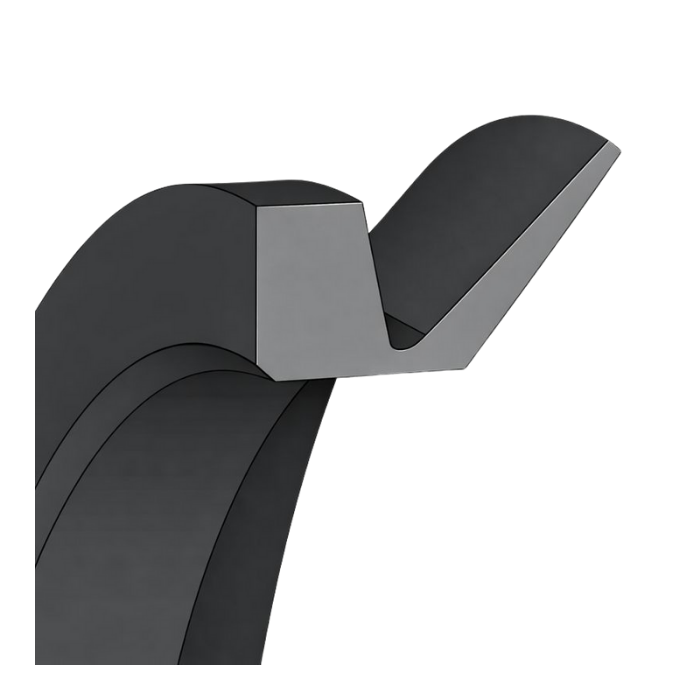

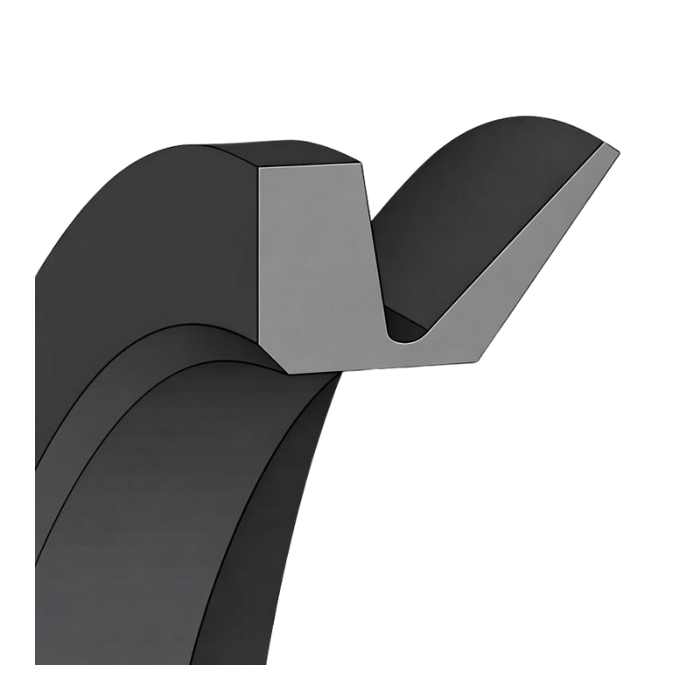

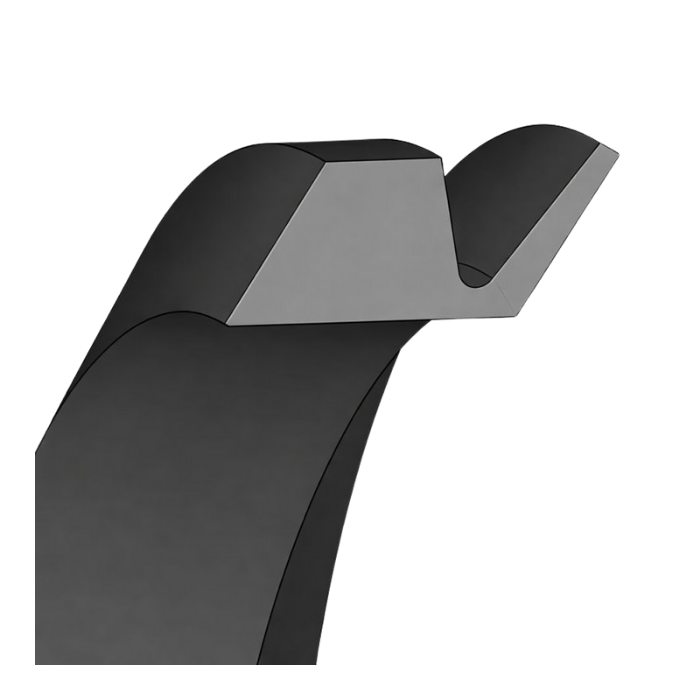

The VA (A10) V-ring is the standard V-ring and therefore the most commonly used version for general applications; this type offers a good balance between stability, lip behavior, and ease of installation. The VS (S10) V-ring was developed with a slimmer profile for situations with limited space, but in practice it remains firmly seated on the shaft and is therefore also often chosen when you want a compact ring that continues to perform reliably under varying speeds. The VL (L10) V-ring is even more compact and more “lightweight” in design; you mainly see this type in lighter-duty applications and more often at lower rotational speeds where you do want an effective dirt barrier but want to add as little installation space and mass as possible. The VE (E10) V-ring is intended for extra-large shafts and heavier industrial environments: a more robust profile that better suits larger diameters and “rough” conditions, such as machines in agriculture and mining where contamination and loads are higher.

The performance of a V-ring depends strongly on the chosen elastomer, because it determines how the lip behaves with temperature, media, and aging. NBR is the logical choice in many standard applications: it combines good wear resistance with excellent resistance to oil, grease, and fuels, and performs especially well in moderate temperature environments. FKM (Viton® type) is the premium option when temperature or chemical exposure becomes more demanding; the material remains stable at high temperatures and is much more resistant to chemicals and aggressive fluids, which is why you see it more often in, for example, the chemical industry, oil and process environments, and other “harsh” applications where you don’t want to take a compound risk. EPDM is also available on request. This is the material you choose for water, steam, and outdoor environments with ozone/UV; it is not suitable for mineral oils and many greases, so the media check is crucial here.

|

Material |

Temperature range (guideline) |

Key properties |

|

NBR |

approx. -40 °C to +100 °C |

Strong in oil/grease/fuel, good wear resistance, cost-effective; less resistant to ozone/UV and some chemicals |

|

FKM |

approx. -20 °C to +200 °C |

Strong at high temperatures, chemicals, and aggressive media; more expensive and less suitable for very low temperatures |

|

EPDM |

approx. -40 °C to +150 °C |

Excellent for water, steam, ozone/UV and weathering; not suitable for mineral oil/grease |

You mainly use V-rings when you want to protect a rotating shaft from everything coming in from the outside, without building a complex sealing arrangement. Think of shafts at bearings, bearing housings, and gearboxes in dusty environments, or applications with splash water, mud, and sand. In those situations, the V-ring rotates with the shaft and keeps contamination away from the sealing point, while also forming a “shield” toward the housing. Because the lip is flexible, the seal remains usable even with slight misalignment and varying rotational speeds. That’s why you often see V-rings used as a pre-seal in front of a bearing or in front of a radial oil seal: the V-ring takes care of the dirty work on the outside, keeping the downstream seal cleaner and helping lubrication stay in place, resulting in less wear.

V-rings are widely available, but the most recognizable product lines come from companies such as Trelleborg (Forsheda V-Ring), SKF, and Freudenberg (including via Dichtomatik lines). In the Benelux, technical wholesalers and specialized sealing suppliers usually stock many common sizes (especially NBR), with FKM/EPDM often available as a variant or on request. When choosing, the logo on the part matters less than whether the supplier can deliver consistently in the right compound, dimensions, and profile, and whether you can reorder quickly for maintenance and overhauls.

|

Design / profile |

anyseals |

Trelleborg |

Forsheda / Stefa |

Dichtomatik |

Taiwan / China |

|

A10 (VA) |

VR-A10 |

VA |

A |

VA |

VA |

|

S10 (VS) |

VR-S10 |

VS |

S |

VS |

VS |

|

L10 (VL) |

VR-L10 |

VL |

L |

VL |

VL |

Start with the shaft size: the inner diameter of the V-ring must be chosen so that the ring clamps firmly after installation, without having to overstretch the rubber. Next, the available installation space determines the profile (VA as the standard, VS/VL if you need something more compact), and you look at the load: for large diameters or a rough environment, you would more often choose VE. The counterface is a second key factor: although V-rings are forgiving, you still want a flat, stable, and reasonably smooth axial counterface so the lip does not wear unevenly. Also check the duty profile: at higher speeds, the protective “slinger” effect increases, but you want the ring to remain mechanically stable and not creep. Finally, match the medium and temperature to the material: NBR is often the baseline choice for oil/grease/fuel at normal temperatures, FKM is the safe option for heat and aggressive media, and EPDM makes sense for water/weather/ozone (but not for oil). And importantly: a V-ring is fundamentally a low-pressure seal; if you truly need to retain oil under pressure, you usually combine it with a primary radial oil seal and use the V-ring as an additional protective layer.

If you would like more information about V-rings, feel free to contact us.

No, a V-ring is intended for low-pressure/pressureless conditions and mainly for dirt and splash-water protection. For pressure sealing you use a radial oil seal or another pressure-capable seal type.

A V-ring seals axially against a counterface and rotates with the shaft; a radial oil seal seals radially on the shaft and is designed to retain oil reliably (often also under higher load).

Within normal limits, yes: thanks to the flexible lip, the ring remains effective with slight misalignment and varying rotational speeds, which makes it suitable for “real-life” machines that are not perfectly aligned.