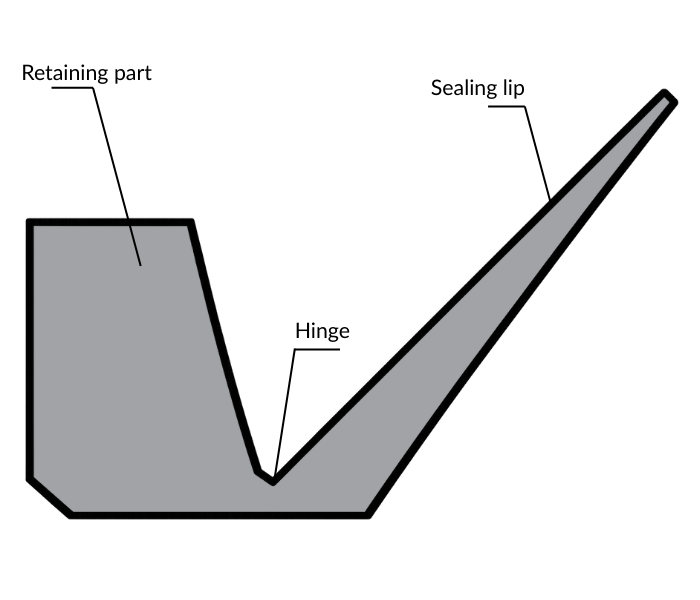

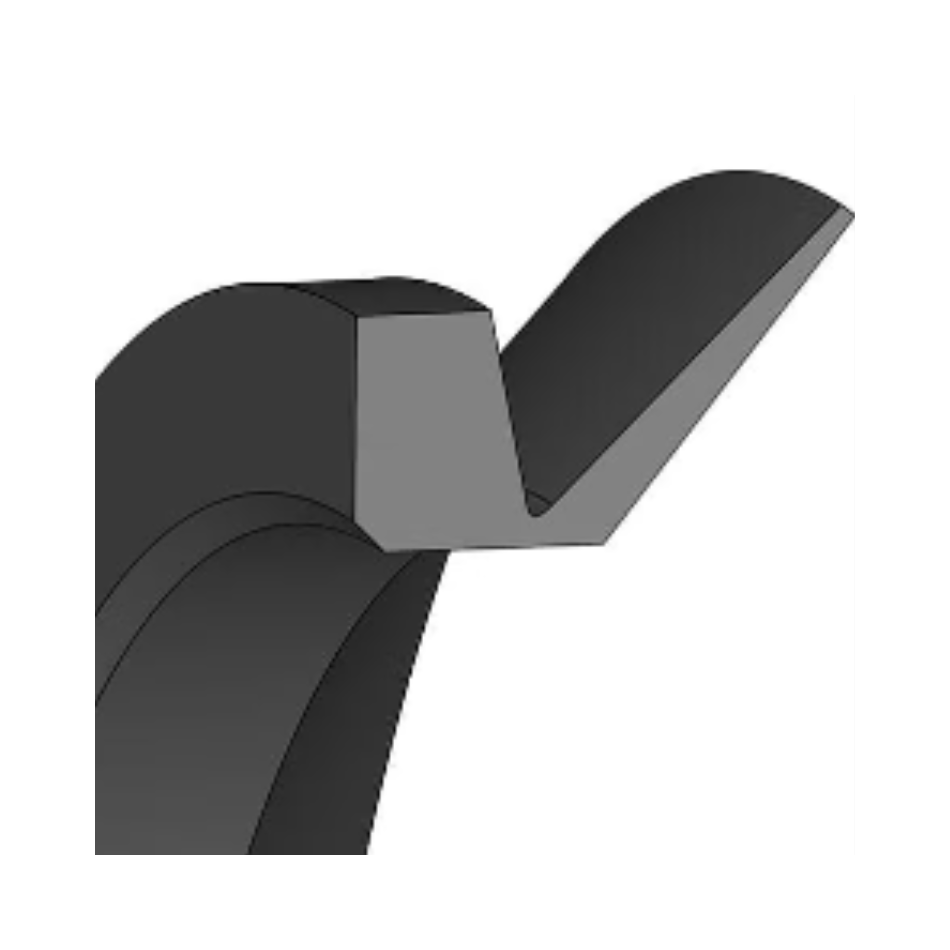

The E10 V-ring is made entirely of elastomer and has a typical V-profile with a solid retaining section and a flexible sealing lip that are connected via a kind of “hinge zone.” During installation, you stretch the ring and slide it into position; due to its inherent tension it clamps around the shaft and rotates with it without any additional retention. The sealing lip makes axial contact with the counterface and can “flex along” with small misalignment, runout and axial movement better than a stiffer seal. That is exactly why this matters for the V-ring E10: it is the heavy-duty design within the V-ring family, with a coarser, more robust geometry and a longer lip. As a result, the ring remains stable in harsh environments, is less sensitive to slight eccentricity, and can cover a larger “working zone” when the counterface is not perfectly located in one fixed position.

You choose the V-ring E10 mainly when you are dealing with heavy contamination or wet conditions and want extra protection for bearings and shaft seals. Think of (heavy) drives, conveyors, industrial fans, gear reducers, pump sets, agricultural or earthmoving machines, and anything exposed to outdoor air, dust or splash water. The E10 V-ring is suitable because it places few demands on shaft and housing machining, is relatively insensitive to eccentricity/coaxiality, and because, due to its operating principle, it increasingly functions as a slinger disc/gap seal at higher circumferential speeds, meaning friction and wear actually decrease at higher speed.

The V-ring E10 is usually supplied in NBR or FKM. NBR (nitrile rubber) is the all-round choice for oil and grease in general mechanical engineering: the material is wear-resistant, widely applicable and usually the most logical option at normal temperatures. The weak point of NBR is that it is less resistant to long-term UV/ozone exposure and weathering, so it can age faster in outdoor installations. FKM (Viton® type) is strong at higher temperatures and generally offers better chemical resistance and higher resistance to ozone and weathering. The downside is that FKM can harden sooner in cold environments and that it is often not necessary in standard oil/grease applications. In practice, this means NBR is usually the standard choice and FKM becomes especially interesting once temperature, media or outdoor conditions become more critical.

|

Material |

Typical temperature range |

Strong in |

Less suitable for |

Note |

|

NBR (Nitrile) |

-40 °C to +100 °C |

Oil/grease (mineral), general mechanical engineering, good wear resistance, all-round & cost-effective |

Long-term UV/ozone/outdoor exposure, higher temperatures |

Standard choice for many industrial applications |

|

FKM (Viton® type) |

-20 °C to +200 °C |

High temperatures, better chemical resistance, often better against ozone/weathering |

Cold environments (hardens sooner), “overkill” for standard oil/grease |

Good choice for heat, more aggressive media or outdoor use |

You determine the correct size primarily based on the nominal shaft diameter, because the V-ring clamps onto the shaft through stretch and inherent tension. Make sure the shaft size and fit are logical within the ISO system of fits (think ISO 286) and avoid a shaft that ends up too small, because the ring may then have less grip. Next, look at the counterface, because the E10 seals axially against a surface that can be formed, for example, by the housing, a cover or a pressed-in plate. That surface must be clean, flat and stiff enough; for surface finish it is advisable to keep roughness and finish level in line with common guideline values (ISO 4287/4288 as reference), because a rough or damaged surface leads to wear and leakage more quickly. Also consider circumferential speed: at standstill the lip presses against the surface with an initial contact pressure, but as speed increases that pressure drops due to centrifugal force, and around 15–20 m/s the lip can (partly) lift, after which the ring works more as a gap seal and slinger disc. Finally, choose the material based on medium and temperature; for standard oil/grease NBR is often the most logical, while FKM is better suited to higher temperatures, chemistry or outdoor conditions. Keep in mind that the V-ring E10 is primarily a protective and contamination seal and not a pressure seal; with pressure or true liquid sealing you usually combine it with a radial shaft seal.

All V-rings work according to the same principle, but the difference lies in profile shape and application area. The E10 V-ring (VE) is the heavy-duty version with a more robust profile and a longer lip, making it a better fit for harsher conditions, larger diameters and installations with greater tolerances. The A10 V-ring (VA) is the standard design you see most often, because it is broadly applicable and usually the right choice when conditions are not extreme. The S10 V-ring (VS) uses a similar lip to the A10, but has a conically extended retaining section so it sits more firmly on the shaft, which is advantageous with vibration or varying loads. The L10 V-ring (VL) is designed for compact installation and has a smaller profile geometry; it is ideal when space is the limiting factor, but it is generally less forgiving than an V-ring E10 type in heavy or heavily contaminated situations. In practice, you choose E10 for maximum robustness, A10 for standard applications, S10 when extra grip is important and L10 when you mainly have limited installation space.

In summary, the V-Ring E10 is an extended sealing lip rotary seal specifically designed for heavy-duty applications. Its purpose is to provide effective shaft sealing, keeping out contaminants and preventing leakage. With its extended sealing lip, the V-Ring E10 offers enhanced sealing performance and durability in demanding operating conditions. Trust in the V-Ring E10 for reliable and efficient sealing solutions in heavy-duty applications.

If you would like more information, or if you do not know which Ring you should have, feel free to contact us.

No. The E10 is intended as a (pre-)seal against contamination and splash water and to retain grease to a limited extent, but not for pressure.

The E10 is the heavy-duty version with a more robust profile and longer lip. A10 is the standard, S10 clamps more firmly onto the shaft, and L10 is more compact for tight installations.

NBR is usually the standard for oil/grease and normal temperatures. Choose FKM for higher temperatures, more aggressive media or when ozone/weathering is more important.

Based on the nominal shaft diameter and a suitable shaft tolerance within the ISO system of fits, so the ring clamps sufficiently without installation issues.

Very important. The surface must be clean, flat and stiff; a counterface that is too rough or damaged can accelerate wear and leakage.

Didn't find the right V-rings Type VE?

Complete the form below and we will help you!