| Product | Product Id | Type | Color | Material | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|

|

25770 | VS-40 | Brown | FKM - FPM - Viton | 1263 | € 9,50 | Details | |

|

25771 | VS-80 | Brown | FKM - FPM - Viton | 15 | € 20,24 | Details | |

|

25772 | VS-65 | Brown | FKM - FPM - Viton | 6 | € 18,95 | Details | |

|

25773 | VS-110 | Brown | FKM - FPM - Viton | 188 | € 44,00 | Details | |

|

25778 | VS-160 | Brown | FKM - FPM - Viton | 46 | € 79,34 | Details | |

|

25780 | VS-18 | Brown | FKM - FPM - Viton | 837 | € 6,27 | Details | |

|

25781 | VS-10 | Brown | FKM - FPM - Viton | 160 | € 2,85 | Details | |

|

25782 | VS-140 | Brown | FKM - FPM - Viton | 120 | € 61,88 | Details | |

|

25783 | VS-7 | Brown | FKM - FPM - Viton | 233 | € 2,46 | Details | |

|

25789 | VS-70 | Brown | FKM - FPM - Viton | 214 | € 22,48 | Details | |

|

25790 | VS-35 | Brown | FKM - FPM - Viton | 1331 | € 8,58 | Details | |

|

25791 | VS-45 | Brown | FKM - FPM - Viton | 527 | € 10,95 | Details | |

|

25792 | VS-50 | Brown | FKM - FPM - Viton | 131 | € 12,10 | Details | |

|

25793 | VS-55 | Brown | FKM - FPM - Viton | 420 | € 15,33 | Details | |

|

25804 | VS-100 | Brown | FKM - FPM - Viton | 39 | € 34,94 | Details | |

|

25807 | VS-180 | Brown | FKM - FPM - Viton | 89 | € 93,14 | Details | |

|

25809 | VS-170 | Brown | FKM - FPM - Viton | 66 | € 86,38 | Details | |

|

25810 | VS-199 | Brown | FKM - FPM - Viton | 109 | € 81,39 | Details | |

|

25813 | VS-25 | Brown | FKM - FPM - Viton | 24 | € 6,55 | Details | |

|

25815 | VS-60 | Brown | FKM - FPM - Viton | 23 | € 16,83 | Details | |

|

25824 | VS-20 | Brown | FKM - FPM - Viton | 136 | € 6,90 | Details | |

|

25828 | VS-190 | Brown | FKM - FPM - Viton | 27 | € 93,68 | Details | |

|

25832 | VS-75 | Brown | FKM - FPM - Viton | 12 | € 23,73 | Details | |

|

25833 | VS-85 | Brown | FKM - FPM - Viton | 9 | € 23,36 | Details | |

|

25834 | VS-90 | Brown | FKM - FPM - Viton | 26 | € 24,82 | Details | |

|

25836 | VS-95 | Brown | FKM - FPM - Viton | 3 | € 33,44 | Details | |

|

25837 | VS-120 | Brown | FKM - FPM - Viton | 106 | € 54,40 | Details | |

|

25840 | VS-130 | Brown | FKM - FPM - Viton | 1 | € 57,80 | Details | |

|

25844 | VS-30 | Brown | FKM - FPM - Viton | 531 | € 7,05 | Details | |

|

25851 | VS-28 | Brown | FKM - FPM - Viton | 302 | € 6,65 | Details |

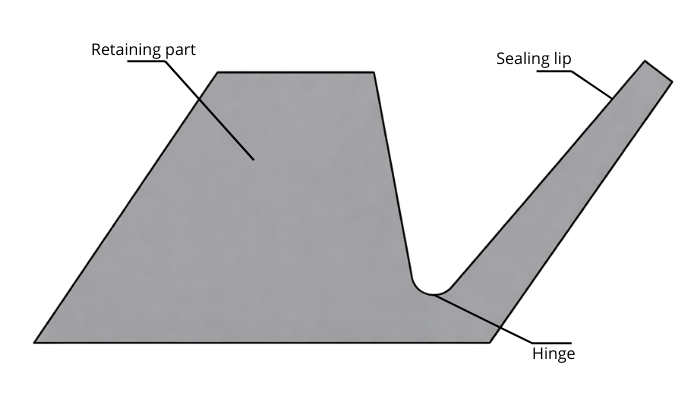

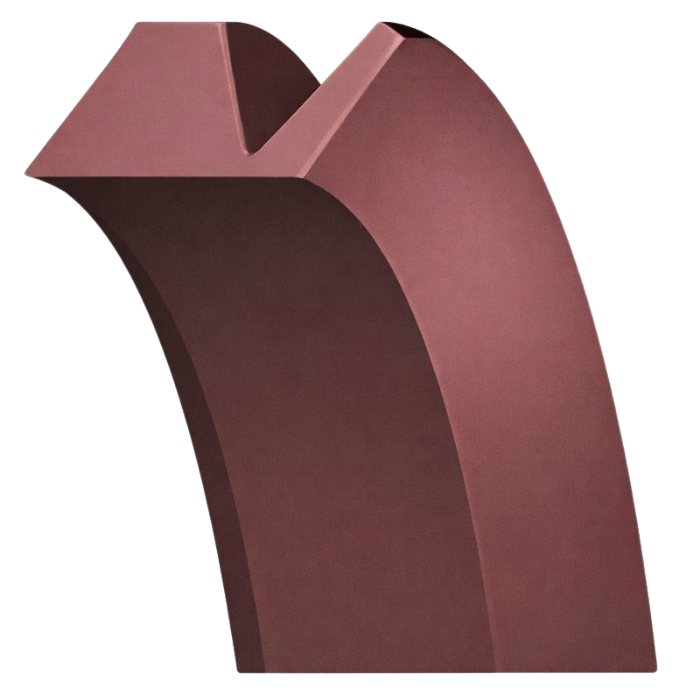

A VS (S10) V-ring is usually made entirely of elastomer. The ring clamps onto the shaft by its own preload and rotates with it, while the sealing lip rests lightly against the counterface. The V-shape creates a flexible “hinge zone”: the lip can deflect and still maintain contact, even with minor misalignment or vibration. In practice, sealing is achieved in two ways. First through contact sealing: the lip forms a physical barrier against contamination and moisture. Second through centrifugal and splash action: during rotation, water, dust and particles are flung outward, keeping the sealing zone cleaner. The VS is therefore primarily a pre-seal or protective seal, which you often place in front of a bearing or in front of a radial shaft seal to catch the “dirty outside.” In practice, the counterface can be formed by various components, such as the housing itself, a housing cover, a pressed plate, the front face of the outer ring of a roller bearing, or even the metal reinforcing ring of a radial shaft seal.

You mainly see the VS (S10) where space is limited and where vibration, contamination or splash water plays a role. In agricultural machinery this is typical because there is a lot of mud, sand, manure and water present, and the extra shaft grip helps prevent shifting or loosening. The VS is also often used in industry and drives such as electric motors, gearboxes and conveyor rollers to protect the bearing arrangement and a seal behind it. In addition, you will find this type in vehicle and off-road applications and in heavier machine building, where a robust first line of defense is needed against dirt and water while the available installation space remains limited. The Viton compound becomes especially relevant when these conditions combine with higher operating temperatures, hot surrounding components, oil/fuel exposure or chemical influence, situations where standard compounds can age faster or lose flexibility.

This page focuses specifically on the Viton option (often specified as FKM or FPM). You typically choose it when temperatures are higher or when you need greater resistance to oils, fuels and more chemically aggressive media. In many applications, FKM offers improved ageing resistance under heat and strong ozone/weather stability, which can be an advantage in outdoor installations or harsh environments. The trade-offs remain important: FPM is generally less favorable at low temperatures (reduced flexibility) and is usually selected when you truly need the extra resistance rather than as a default for standard grease-and-dirt protection.

|

Material |

Typical temp. range (°C) |

Key properties (short) |

|

FKM (Viton®) |

approx. -20 to +200 |

Strong in heat and chemicals (and often fuels/oils); more expensive and less flexible at low temps (compound-dependent) |

The V-ring VA is the standard and most universal design with the widest size range; it is compact and easy to use in many machines. The VS (S10) is the slimmer variant with typically more grip on the shaft due to the conically extended clamping section, making it more stable under vibration and at higher speeds, and particularly interesting when radial installation space is limited. The V-ring VL (L10/lightweight) is lighter and thinner and often becomes attractive at larger diameters to limit mass and centrifugal effects, but it is generally less robust in very heavy contamination. The V-ring VE is the heavy-duty variant for very large diameters and harsh industrial conditions; it is robust but requires more installation space and sometimes more attention during installation.

The choice starts with the shaft size, because sizing is generally linked to the nominal shaft diameter and the ring clamps onto the shaft by preload. Then you look at the available installation space: the VS is especially interesting when radial space is limited, but you must ensure you can position the ring axially against a suitable counterface. Next, you select the compound based on the medium and the environment. For higher temperatures, oil/fuel exposure or chemical influence, Viton (FKM/FPM) is typically the step up compared to standard compounds, especially when long-term ageing stability matters. Consider the operating conditions as well: a VS (S10) is essentially a pressure-free axial seal and is not intended to hold system pressure; it can retain a little grease or oil mist, but under real pressure the lip will tend to deflect or leak. Speed also matters: circumferential speeds up to about 10–12 m/s are often considered safe for continuous contact operation. Up to roughly 10 m/s, friction losses typically increase almost linearly with circumferential speed; around 15–20 m/s the lip pressure can decrease due to centrifugal force and the ring starts to function more like a splash flange or “slinger” (less friction and wear, but different sealing behavior). The counterface remains crucial in all cases: it must be clean, flat and sufficiently rigid to provide even contact. Finally, take the level of contamination into account, because in heavily contaminated environments additional shielding (such as a splash guard or more robust protection) can make a significant difference in service life, especially since temperature, medium and speed together determine how long the ring continues to perform properly.

|

Design / profile |

anyseals |

Trelleborg |

Forsheda / Stefa |

Dichtomatik |

Taiwan / China |

|

S10 V-ring |

VR-S10 |

VS |

S |

VS |

VS |

In summary, the V-Ring S10 is a specialized rotary seal designed with an additional conically extended retaining part for enhanced secure seating on the shaft. Its purpose is to provide optimal shaft sealing, preventing the ingress of contaminants and leakage of grease. With its design enhancement, the V-Ring S10 ensures reliable and effective sealing performance, even in demanding operating conditions. Choose the V-Ring S10 for superior shaft sealing solutions with enhanced secure seating.

If you would like more information, of if you do not know which Ring you should have, feel free to contact us.

No. This is essentially a pressure-free axial seal for protection against contamination and splash water, not for holding system pressure.

The VS has a slimmer profile and typically more clamping area and grip on the shaft, making it more stable under vibration and at higher speeds.

Only to a limited extent. A V-ring can retain grease or oil mist to some degree, but it is mainly intended as a pre-seal and not as a primary oil seal.

EPDM is often a logical choice because of its ozone and UV resistance, but you should always check whether the medium is compatible because EPDM is often unsuitable for mineral oil and grease. In many grease/oil applications, NBR remains the standard, possibly with additional protection against UV/ozone.

A thin film can help prevent dry running at start-up. Don’t overdo it, because too much grease can attract dirt.

Didn't find the right VS FKM?

Complete the form below and we will help you!