| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Spring | Material Spring | Dust lip | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

47267 | Oil Seal | 17 | 30 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 813 | € 3,84 | Details | ||

|

47096 | Oil Seal | 125 | 155 | 18 | NBR - Nitrile | Steel | Yes | Steel | No | 123 | € 20,58 | Details | ||

|

47154 | Oil Seal | 140 | 170 | 20 | NBR - Nitrile | Steel | Yes | Steel | No | 129 | € 23,21 | Details | ||

|

47186 | Oil Seal | 15 | 24 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 0 | € 3,38 | Details | Quote | |

|

47188 | Oil Seal | 15 | 26 | 7 | FPM - VITON | Steel | Yes | Steel | No | 0 | € 10,38 | Details | Quote | |

|

47237 | Oil Seal | 160 | 190 | 23 | NBR - Nitrile | Steel | Yes | Steel | No | 236 | € 22,64 | Details | ||

|

47239 | Oil Seal | 160 | 195 | 21 | NBR - Nitrile | Steel | Yes | Steel | No | 70 | € 26,86 | Details | ||

|

47255 | Oil Seal | 17 | 28 | 6.5 | NBR - Nitrile | Steel | Yes | Steel | No | 409 | € 3,38 | Details | ||

|

47260 | Oil Seal | 17 | 28 | 8 | NBR - Nitrile | Steel | Yes | Steel | No | 120 | € 3,38 | Details | ||

|

47088 | Oil Seal | 122 | 152 | 21 | NBR - Nitrile | Steel | Yes | Steel | No | 386 | € 20,58 | Details | ||

|

47270 | Oil Seal | 17 | 33 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 0 | € 3,89 | Details | Quote | |

|

47309 | Oil Seal | 18 | 32 | 8 | FPM - VITON | Steel | Yes | Steel | No | 455 | € 10,38 | Details | ||

|

47311 | Oil Seal | 18 | 32 | 8 | NBR - Nitrile | Steel | Yes | Steel | No | 542 | € 3,89 | Details | ||

|

47351 | Oil Seal | 190 | 225 | 21 | NBR - Nitrile | Steel | Yes | Steel | No | 180 | € 41,24 | Details | ||

|

47362 | Oil Seal | 20 | 31 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 711 | € 3,89 | Details | ||

|

47370 | Oil Seal | 20 | 35 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 101 | € 3,89 | Details | ||

|

47372 | Oil Seal | 20 | 35 | 8 | NBR - Nitrile | Steel | Yes | Steel | No | 296 | € 3,89 | Details | ||

|

47376 | Oil Seal | 20 | 40 | 14 | NBR - Nitrile | Steel | Yes | Steel | No | 0 | € 3,64 | Details | Quote | |

|

47076 | Oil Seal | 120 | 150 | 22 | NBR - Nitrile | Steel | Yes | Steel | No | 542 | € 19,30 | Details | ||

|

47029 | Oil Seal | 110 | 140 | 22 | NBR - Nitrile | Steel | Yes | Steel | No | 299 | € 17,91 | Details | ||

|

46972 | Oil Seal | 15 | 24 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 883 | € 3,84 | Details | ||

|

46921 | Oil Seal | 17 | 28 | 6.5 | NBR - Nitrile | Steel | Yes | Steel | No | 48 | € 4,33 | Details | ||

|

46885 | Oil Seal | 44.45 | 57.15 | 6.35 | NBR - Nitrile | Steel | Yes | Steel | No | 0 |

Request

|

Details | Quote | |

|

46852 | Oil Seal | 140 | 170 | 14 | FPM - VITON | Steel | Yes | Steel | No | 0 |

Request

|

Details | Quote | |

|

46836 | Oil Seal | 17 | 33 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 937 | € 2,41 | Details | ||

|

46834 | Oil Seal | 145 | 170 | 18 | NBR - Nitrile | Steel | Yes | Steel | No | 0 |

Request

|

Details | Quote | |

|

46831 | Oil Seal | 15 | 24 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 51 | € 1,46 | Details | ||

|

46647 | Oil Seal | 17 | 28 | 7 | FPM - VITON | Steel | Yes | Steel | No | 0 |

Request

|

Details | Quote | |

|

46646 | Oil Seal | 15 | 24 | 7 | FPM - VITON | Steel | Yes | Steel | No | 75 |

Request

|

Details | Quote | |

|

46623 | Oil Seal | 17 | 28 | 7 | NBR - Nitrile | Steel | Yes | Steel | No | 1121 | € 3,84 | Details |

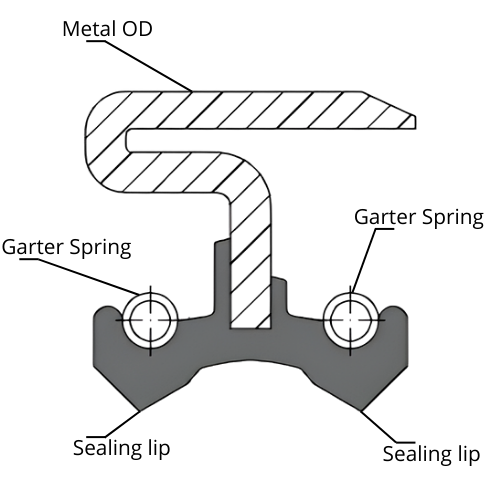

The DB oil seal consists of a metal outer diameter into which two separate elastomeric sealing lips are integrated. Both lips are supported by a garter spring, allowing each lip to apply a constant radial sealing force to the shaft independently. As a result, each lip functions as a fully active seal rather than as a secondary or protective lip. This configuration enables the seal to provide effective sealing on both sides of the shaft, making it suitable for separating two different media within a single shaft passage.

The metal outer casing is installed in the housing by means of a metal-to-metal press fit and largely determines the positioning accuracy and stability of the seal. Compared to seals with a rubber coated OD, this design offers higher dimensional stability and shape retention, particularly in larger diameters or applications where mechanical loads and alignment accuracy are essential. As a result, the stays in position and is less likely to deform under operating conditions.

On the other hand, this construction places higher demands on housing quality and controlled installation. Because the metal outer diameter does not compensate for irregularities in the bore, housing tolerances, surface finish, and roundness must remain within specified limits. In light-metal housings or housings with a rougher surface finish, additional sealing at the outer diameter may be required, for example by using a sealing compound or a coated outer surface. This makes the oil seal DB structurally robust, but less forgiving than variants with a fully elastomeric outer diameter.

DB oil seals are used in rotating machine components where two media must remain separated within a single shaft passage. Typical examples include industrial gearboxes with separate lubrication circuits, drive systems in which bearing lubrication and transmission lubrication must remain isolated, and pump units where different fluids are present on either side of the seal. This type of rotary shaft seal is also used in certain reduction gearboxes, mixers, and process installations to prevent mixing of oil and grease or two different types of oil.

The suitability of the oil seal DB lies not only in the presence of two sealing lips, but primarily in the fact that both lips are functionally equivalent and actively sealing. This allows a single compact component to perform a task that would otherwise require two separate oil seals arranged back-to-back. The result is a simpler mechanical design, reduced installation space, and a lower risk of tolerance issues or assembly deviations within the sealing arrangement.

The material selection of a DB oil seal has a significant impact on its suitability for a given application. NBR is the standard material and is suitable for mineral oils and greases across a wide temperature range. It offers a good balance between wear resistance, elasticity, and cost efficiency.

For higher temperatures or chemically more aggressive lubricants, FKM is often the preferred choice, providing greater thermal and chemical stability, even with reduced flexibility at low temperatures. ACM is suitable for oils containing additives, while HNBR is recommended for applications involving higher mechanical loads or extended service life.

Special elastomers such as silicone, CR, or EPDM are used only for specific media or temperature requirements and always require careful compatibility verification. For corrosive environments, springs and reinforcing rings can be supplied in stainless steel.

|

Material |

Temperature Range |

Key Properties |

|

NBR |

–40 °C to +100 °C |

Good resistance to mineral oils and greases, good wear resistance, flexible, cost-effective |

|

FKM |

–20 °C to +150 °C |

High temperature resistance, excellent chemical resistance, suitable for aggressive lubricants, lower flexibility at low temperatures |

|

HNBR |

–30 °C to +140 °C |

Improved mechanical strength, better heat and aging resistance than NBR, good oil resistance |

|

ACM |

–20 °C to +150 °C |

Resistant to oils with additives, good thermal stability, limited low-temperature flexibility |

|

VMQ |

–60 °C to +180 °C |

Excellent low-temperature flexibility, good heat resistance, poor wear and oil resistance |

|

CR |

–30 °C to +100 °C |

Moderate oil resistance, good weather and ozone resistance, general-purpose elastomer |

|

EPDM |

–40 °C to +120 °C |

Excellent resistance to water, steam, and brake fluids, not suitable for mineral oils |

Within the range of oil seals, the oil seal DB occupies a clearly defined niche. Unlike SC oil seals, it is not intended for sealing a single medium, but for applications in which two media must remain separated. Compared to TC oil seals, the difference is fundamental: in a TC oil seal, the second lip functions as a dust lip, whereas in a DB rotor seal both lips are spring-supported and actively sealing.

In addition, the DB oil seal is distinguished by its metal outer diameter, which ensures stable and accurate seating in the housing. This makes it more dimensionally stable than rubber-OD variants, but also less tolerant of imperfections in the housing. As such, the oil seal DB is not a universal solution, but a targeted choice for specific sealing challenges where medium separation is the primary focus.

Correct selection of a oil seal DB starts with proper dimensions and tolerances. The shaft must match with ISO h11, have a minimum hardness of 45 HRC, and feature a fine surface finish to prevent wear and leakage. The shaft surface should be torsion-free and finished to a surface roughness of Ra 0.2–0.8 μm, Rz 1–5 μm, with a maximum Rmax ≤ 6.3 μm to ensure reliable sealing and minimal wear. For the housing bore, a tolerance of ISO H8 is recommended, with a surface roughness of Ra 0.8–3.2 μm, Rz 6.3–16 μm, and a maximum Rmax ≤ 16 μm, particularly important for seals with a metal OD. The housing should be manufactured to ISO H8 tolerances and provide a smooth surface for a reliable metal-to-metal press fit.

In addition, operating temperature, type of medium, circumferential speed, and pressure play a decisive role. For standard material combinations, the DB oil seal is designed for operating temperatures from –40 °C to +100 °C, with a recommended maximum continuous temperature of +80 °C, a maximum pressure of 0.02 MPa, and a circumferential speed of up to 5 m/s, depending on operating conditions. DB oil seals are intended for pressureless or very low-pressure applications and have a limited maximum circumferential speed. When synthetic lubricants or non-standard media are used, material compatibility must be verified in advance.

Oil Seals are produced in different factories. The different factories and suppliers therefore use their own product names for the Oil Seals for the different types. Find the cross reference of different oil seal factories/suppliers in the table below:

|

Manufacturer |

DB Oil Seal Designation |

|

Dichtomatik |

WBD |

|

Anyseals |

OS-D15 |

|

Elring |

BD |

|

Eriks |

M-DUO |

|

FST |

B1 DUO |

|

Goetze |

822 D |

|

Kaco |

DFD |

|

Stefa |

BK |

|

NOK / Taiwan NOK |

DB |

|

Kimman |

KB-DUO |

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

A DB rotary shaft seal features two spring-supported, actively sealing lips and is designed to separate two different media, whereas most other oil seals are intended to seal only a single medium.

No. DB oil seals are designed for pressureless or very low-pressure applications, typically up to 0.02 MPa.

The metal outer diameter provides high dimensional stability and ensures a precise, rigid press fit in the housing, particularly beneficial for larger diameters and mechanically demanding applications.

Yes, but caution is required. In light-metal or rough housings, additional sealing at the outer diameter may be necessary, such as using a sealing compound or a coated outer surface.

Depending on the elastomer material, DB oil seals are suitable for mineral oils, many synthetic lubricants, greases, and other specific media, provided material compatibility is confirmed.

Didn't find the right Oil Seal DB - Rotary Shaft Seal?

Complete the form below and we will help you!