| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

51405 | Oil Seal | 340 | 372 | 16 | FPM - VITON | Steel | Steel | Yes | No | Brown | 0 |

Request

|

Details | Quote | |

|

51410 | Oil Seal | 420 | 460 | 20 | FPM - VITON | Steel | Steel | Yes | No | Brown | 0 |

Request

|

Details | Quote | |

|

51412 | Oil Seal | 482.6 | 520.7 | 19.05 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote |

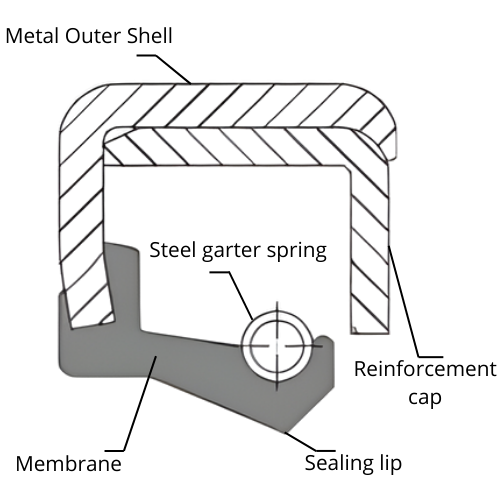

An SA Oil Seal is a rotary shaft seal which consists of an elastomer sealing lip, a metal outer diameter and a reinforcement cap. The spring-loaded sealing lip retains oil or grease inside while the metal outer shell ensures a reliable and rigid press-fit in the housing. Due to the metal reinforcement structure, the oil seal maintains its shape even under vibration, thermal expansion, or dynamic loading. The reinforcement cap makes the SA oil seal less sensitive to minor installation deviations or slight misalignments. Since the design doesn’t contain a dust lip, the oil seal SA is solely intended for internal sealing, and it doesn’t protect against external contamination. That’s why this type of oil seal is mainly used in gearboxes, electric motors, pumps, compressors, and precision drive systems operating in clean environments where the focus is on internal oil sealing and structural stability.

The SA oil seal is particularly suitable for equipment requiring a rigid metal-to-metal housing fit and stable sealing performance under continuous rotation. It is frequently used in industrial gearboxes, where accurate shaft alignment and consistent lubrication retention are essential. In electric motors and generators, the SA type provides a secure housing fit for applications where vibration or thermal fluctuation may occur. The seal is also commonly applied in pumps and compressors that run at medium to high speeds and rely on a precise and stable casing fit.

Beyond these systems, the SA oil seal is often found in machinery with larger shaft diameters, such as industrial mixers, blowers, and mechanical drive assemblies that require a structurally rigid sealing profile. When paired with external dust-exclusion elements like V-rings or AS-10 axial seals, the SA type can also be used effectively in agricultural machines, construction equipment, and compact industrial power units that operate in controlled or semi-clean environments.

The SA oil seal, internationally recognized as the Taiwanese designation for the OS-C10 type, is marketed under many different codes and references depending on the brand or supplier. The table underneath shows the different codes used by manufacturers and suppliers.

|

Brand / Standard |

Equivalent to SA |

|

Dichtomatik |

WC |

|

Anyseals |

OS-C10 |

|

B+S |

TR-B |

|

Chicago R |

CRWH1 |

|

Elring |

C |

|

Eriks |

GV |

|

FP Paris |

L2 |

|

FST |

B2 |

|

Goetze |

824 N |

|

Kaco |

DFK |

|

Kramp |

DB |

|

National |

45 |

|

Paulstra |

EEP |

|

Pioneer W |

R1 |

|

Rolf |

RC |

|

Stefa |

DB |

|

Taiwan / NOK |

SA |

|

Vota |

B2 |

|

Ebele |

B2 |

|

Kimman |

KC |

The oil seal SA type stands out due to its rigid metal outer diameter and reinforcement cap, which makes the seal especially suitable for precise metal housings and larger shaft diameters. The simpler single lip design offers low friction and less heat generation than oil seals with a double lip, which is beneficial at higher speeds. Compared to the TA oil seal and the TB oil seal, which both include a dust lip, the SA oil seal is much more efficient in applications where no external contamination is present. In comparison with the oil seal SC type and the oil seal TC type (with an elastomer OD), the SA oil seal offers a much stiffer and reliable press fit, particularly in metal housings that require high structural stability. This makes the SA a suitable choice for systems where dimensional accuracy, low friction, and long-term internal lubrication retention are essential. When additional external protection is needed, the SA can be combined with axial seals such as AS-10 or V-rings.

When selecting a SA rotary shaft seal, you should check on several parameters to ensure optimal performance. The shaft diameter must match the inner diameter of the seal, while the housing bore must meet ISO H8 tolerance to guarantee a reliable interference fit with the metal outer case. Shaft roughness should be between Ra 0.2 – 0.8 µm, with a minimum hardness of 45 HRC to prevent wear. Material selection depends on operating temperature, lubricant type, and chemical exposure. NBR is generally suitable for mineral oils, while FKM or HNBR is recommended for synthetic lubricants or higher temperatures. Because the SA seal has no dust lip, it should only be used in clean environments or in combination with external dust-exclusion solutions. Shaft speed must also be considered, as excessive heat generation at the sealing edge can reduce service life.

The SA oil seal is available in several elastomer and spring material combinations to meet different temperature, chemical, and operating conditions. The tables below provide an overview of the available materials and their key properties.

|

Lip Material |

Temperature Range |

Properties |

|

NBR |

–40°C to +100°C |

Oil-resistant, wear-resistant, economical |

|

FKM (Viton®) |

–20°C to +200°C |

Excellent heat and chemical resistance |

|

HNBR |

–30°C to +150°C |

High resistance to heat, oil, and wear |

|

ACM |

–25°C to +150°C |

Very good resistance to hot oil and oxidation |

|

EPDM |

–40°C to +140°C |

Resistant to water, steam, and certain chemicals (not for oil) |

|

VMQ (Silicone) |

–60°C to +200°C |

Excellent flexibility at low temperatures |

|

Spring Material |

Properties |

Application |

|

Carbon Steel |

High stability, strong elasticity, suitable for standard oils and greases |

General industrial use, NBR and ACM seals |

|

Stainless Steel 304 (SS-304) |

Corrosion-resistant, suitable for humid or chemically aggressive environments, higher temperature resistance |

Used with FKM, HNBR, EPDM, or VMQ; higher-temperature or corrosive conditions |

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

It’s suitable for clean industrial environments where internal lubrication must be retained without exposure to external contamination.

No, the oil seal SA is a single lip sealing without a dust lip.

A metal outer case provides a rigid and precise interference fit, especially in metal housings or applications with high loads or vibration.

Yes, provided the correct material is selected. FKM offers improved heat resistance at higher speeds.

Ensure the shaft and housing are clean, burr-free, and within tolerance. Press the seal in evenly without damaging the lip or metal case. Always lubricate the sealing lip with compatible oil or grease before installation to prevent initial dry running and ensure proper seating of the seal.

Didn't find the right Oil Seal SA - Rotary Shaft Seal?

Complete the form below and we will help you!