| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

49864 | Oil Seal | 75 | 100 | 13 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 9,64 | Details | Quote | |

|

49862 | Oil Seal | 70 | 85 | 8 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 7,55 | Details | Quote | |

|

49860 | Oil Seal | 69.85 | 88.9 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | No | Brown | 40 | € 25,92 | Details | ||

|

49859 | Oil Seal | 68.28 | 95.25 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | No | Brown | 0 | € 31,08 | Details | Quote | |

|

49854 | Oil Seal | 55 | 78 | 8 | FPM - VITON | Steel | SS-304 | Yes | No | Brown | 96 | € 21,66 | Details | ||

|

49853 | Oil Seal | 55 | 78 | 8 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 123 | € 6,82 | Details | ||

|

49851 | Oil Seal | 52 | 68 | 8 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 7,07 | Details | Quote | |

|

49848 | Oil Seal | 42 | 50 | 7 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 489 | € 4,92 | Details | ||

|

49841 | Oil Seal | 34 | 46 | 10 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 101 | € 4,59 | Details | ||

|

49838 | Oil Seal | 32 | 50 | 7 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 4,92 | Details | Quote | |

|

49837 | Oil Seal | 30 | 47 | 5 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 442 | € 4,59 | Details | ||

|

49835 | Oil Seal | 29 | 42 | 7 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 303 | € 4,08 | Details | ||

|

49834 | Oil Seal | 28 | 38 | 6 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 859 | € 3,57 | Details | ||

|

49833 | Oil Seal | 27 | 35 | 4 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 2801 | € 3,06 | Details | ||

|

49832 | Oil Seal | 21 | 30 | 6.5 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 2,66 | Details | Quote | |

|

49831 | Oil Seal | 19.05 | 31.75 | 6.35 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 1278 | € 3,06 | Details | ||

|

49827 | Oil Seal | 12.7 | 25.4 | 6.35 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 156 | € 2,66 | Details | ||

|

49826 | Oil Seal | 11 | 26 | 6 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 370 | € 2,66 | Details | ||

|

49825 | Oil Seal | 8 | 30 | 7 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 2,66 | Details | Quote | |

|

49759 | Oil Seal | 80 | 100 | 10 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 9,64 | Details | Quote | |

|

49742 | Oil Seal | 62 | 90 | 10 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 8,16 | Details | Quote | |

|

49728 | Oil Seal | 50 | 65 | 10 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 8 | € 6,68 | Details | ||

|

49726 | Oil Seal | 48 | 65 | 10 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 6,68 | Details | Quote | |

|

49692 | Oil Seal | W-DRAL | 25 | 35 | 6 | FPM - VITON | Steel | SS-304 | Yes | No | Brown | 210 | € 10,88 | Details | |

|

49681 | Oil Seal | 32 | 52 | 10 | EPDM | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

49680 | Oil Seal | 15 | 40 | 10 | EPDM | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

49679 | Oil Seal | 45 | 62 | 8 | NBR - Nitrile | Steel | Steel | Yes | No | Black | 0 | € 6,68 | Details | Quote | |

|

49678 | Oil Seal | 75 | 100 | 13 | EPDM | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

49677 | Oil Seal | 55 | 78 | 8 | EPDM | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote | |

|

49676 | Oil Seal | 52 | 68 | 8 | EPDM | Steel | Steel | Yes | No | Black | 0 |

Request

|

Details | Quote |

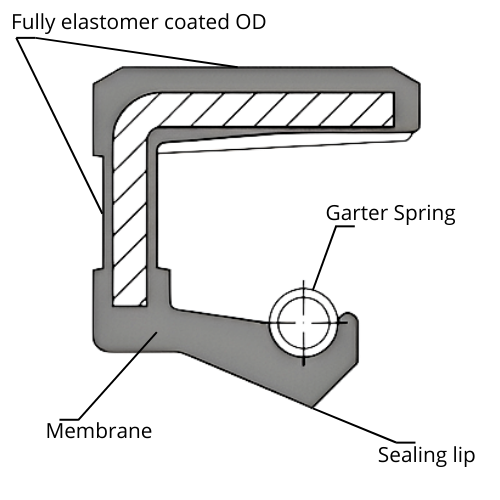

An SC Plus oil seal is an advanced rotary shaft seal that prevents lubricants such as oil or grease from leaking out while also protecting against the ingress of dust, water, or other contaminants. This seal belongs to the category of non-pressure rotary seals and is designed for applications with no or only minimal pressure load. The SC Plus is constructed around a steel reinforcement ring that is fully encased in elastomer, ensuring a secure static seal in the housing, even with increased surface roughness or thermal expansion of light alloys. The single sealing lip is supported by a stainless-steel garter spring that applies constant, even pressure to the rotating shaft. The absence of an extra dust lip reduces friction and heat generation, which extends the seal its service life. Compared to the standard oil seal SC, the oil seal SC plus offers significant improvement in performance and durability in demanding environments.

The SC Plus oil seal is widely used in sectors that require durability, heat resistance, and chemical resistance. In mechanical and equipment engineering, it is found in gearboxes, reducers, and other drive units. In agriculture- and construction machinery, the oil seal SC plus offers a reliable sealing in transmissions, hydraulic systems, or engine components exposed to fertilizers, moisture, and temperature fluctuations. The SC plus oil seal also helps maintain a leakage free operation in electromotors and industrial generators, even with high rotating speed and extended use. Since the seal does not feature a dust lip, it is best suited for use in enclosed systems or relatively clean environments where internal oil retention and resistance to external chemical exposure are the primary concerns.

The standard SC plus oil seal contains an FKM (Viton) sealing lip with 80 share A hardness, combined with a stainless-steel garter spring. This configuration offers a temperature range between -20°C and +200°C with great chemical resistance against oils, fuels and fertilizers. For applications with different requirements, other elastomers are available, including NBR, ACM, HNBR, VMQ, CR, and EPDM. Each material has its own unique properties which can be tailored to the used medium, temperature and mechanical load.

|

Material |

Temperature Range |

Resistance |

Characteristics |

|

NBR |

-30°C to +100°C |

Mineral oils, greases, water |

Economical, wear-resistant, widely applicable |

|

FKM (Viton) |

-20°C to +200°C |

Hot oils, fuels, chemicals |

Highly heat- and chemically resistant |

|

ACM |

-20°C to +150°C |

Transmission oils, ATF |

Heat- and oxidation-resistant |

|

HNBR |

-30°C to +150°C |

Oils, ozone, coolants |

High mechanical strength |

|

VMQ |

-50°C to +180°C |

Light oils, dry air |

Flexible at low temperatures, low friction |

|

CR |

-40°C to +120°C |

Ozone, weathering |

Aging-resistant, less oil-compatible |

|

EPDM |

-40°C to +150°C |

Water, brake fluid |

Not oil-compatible, good for polar media |

The SC plus oil seal stands out due to its performance at high temperature, chemical resistance and environments where corrosion is a risk. The oil seal SC plus is resistant against operating temperatures up to 160 and offers a reliable sealing at high rotating speed as long as the application is non-pressurized. Thanks to the fully elastomer coated outer diameter, the SC plus oil seal is well-suited for use in aluminum or cast-iron housing with differing expansion coefficients or higher surface roughness. A key advantage over double-lip seals like the oil seal TC Plus is its lower friction and therefore less heat generation. While the standard SC oil seal is usually made of NBR the standard SC plus is made of FKM which delivers significantly longer service life under heavy-duty conditions. On the other hand, the SC plus as well as the standard SC oil seal is less suitable for applications where external contamination is a concern. In those situations, the TC plus offers a better protection with its additional dust lip, although at the cost of increased friction. Thanks to the elastomer-encased reinforcement ring, the SC Plus also provides excellent protection against fretting corrosion, maintaining sealing integrity under micro-vibrations or fluctuating loads.

When selecting an SC Plus oil seal, several technical factors must be considered. The shaft fit should comply with ISO h11 tolerances, while the housing bore should meet ISO H8. For effective dynamic sealing, the shaft surface roughness should range from Ra 0.2 to 0.8 µm; the housing bore may be slightly rougher (Ra 1.6 to 6.3 µm), depending on material and installation conditions. For optimal performance, a minimum shaft hardness of 45 HRC is recommended. Additionally, surface finish should stay within Rz 1–5 µm and Rmax ≤ 6.3 µm for shafts, and Rz 10–20 µm and Rmax ≤ 25 µm for housings. Always ensure proper lubrication on the sealing lip during assembly to avoid dry running and promote a stable oil film. Finally, material selection is essential: match the rubber compound to the lubricant, operating temperature, and any potential chemical exposure. This ensures optimal performance and prevents premature wear or leakage in critical applications.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The primary difference between the SC and SC Plus lies in the construction of the metal reinforcement ring. In the SC Plus, this ring is fully encapsulated in elastomer, offering superior protection against corrosion and ensuring a more secure static seal.

Only if the application is in a clean, enclosed environment. The SC Plus has no dust lip, making it less suitable for conditions with external dirt, mud, or moisture. In those cases, a TC Plus is the better choice.

The standard SC Plus with a Viton sealing lip can handle continuous temperatures up to 160°C, with peaks up to 200°C depending on the load and lubricant used.

For optimal performance, use ISO h11 for the shaft and ISO H8 for the housing bore. Also ensure proper surface roughness and avoid dry running during initial rotation.

Didn't find the right Oil Seal SC Plus - Rotary Shaft Seal?

Complete the form below and we will help you!