| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

44215 | Oil Seal | 380 | 430 | 19 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 43 |

Request

|

Details | Quote | |

|

45378 | Oil Seal | 35 | 72 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 698 | € 8,11 | Details | ||

|

45377 | Oil Seal | 25 | 62 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 2,19 | Details | Quote | |

|

45340 | Oil Seal | 140 | 170 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 105 | € 23,21 | Details | ||

|

45339 | Oil Seal | 80 | 120 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 57 | € 15,26 | Details | ||

|

45336 | Oil Seal | 22.22 | 34.92 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 544 | € 3,90 | Details | ||

|

45177 | Oil Seal | 149 | 170 | 14.5 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 10,27 | Details | Quote | |

|

45176 | Oil Seal | 146.05 | 168.27 | 19.05 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 10,27 | Details | Quote | |

|

45175 | Oil Seal | 140 | 170 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 242 | € 23,21 | Details | ||

|

45174 | Oil Seal | 139.7 | 165.1 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 58 | € 14,00 | Details | ||

|

45173 | Oil Seal | 125 | 162 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 9,79 | Details | Quote | |

|

45172 | Oil Seal | 125 | 150 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 7,14 | Details | Quote | |

|

45171 | Oil Seal | 75 | 115 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 410 | € 5,48 | Details | ||

|

45170 | Oil Seal | 600 | 640 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 179,23 | Details | Quote | |

|

45169 | Oil Seal | 200 | 230 | 18 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 42 | € 18,89 | Details | ||

|

45168 | Oil Seal | 190 | 220 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 168 | € 36,45 | Details | ||

|

45167 | Oil Seal | 165.1 | 234.95 | 19.05 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 19,52 | Details | Quote | |

|

45166 | Oil Seal | 175 | 210 | 15 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 31,65 | Details | Quote | |

|

45165 | Oil Seal | 230 | 250 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 24,09 | Details | Quote | |

|

45164 | Oil Seal | 210 | 250 | 15 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 8 | € 48,92 | Details | ||

|

45163 | Oil Seal | 203.2 | 254 | 15.87 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 52 | € 52,75 | Details | ||

|

45162 | Oil Seal | 203 | 230 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 18,89 | Details | Quote | |

|

45161 | Oil Seal | 200 | 240 | 15 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 184 | € 54,12 | Details | ||

|

45160 | Oil Seal | 390 | 425 | 18 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 76 |

Request

|

Details | Quote | |

|

45159 | Oil Seal | 260 | 290 | 16 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 5 | € 29,10 | Details | ||

|

45093 | Oil Seal | 92.07 | 114.3 | 11.99 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 5,48 | Details | Quote | |

|

45083 | Oil Seal | 100 | 130 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 78 | € 6,86 | Details | ||

|

45082 | Oil Seal | 530 | 580 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 150,84 | Details | Quote | |

|

45079 | Oil Seal | 145 | 167 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 10,27 | Details | Quote | |

|

45078 | Oil Seal | 125 | 143 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 6,74 | Details | Quote |

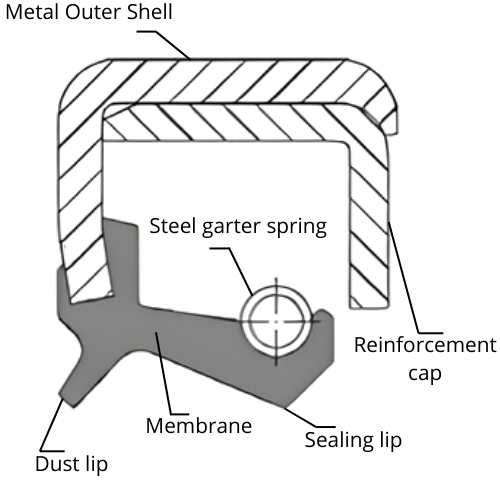

The TA oil seal operates with an elastomer sealing lip that is continuously pressed against the rotating shaft by a spiral spring. This spring maintains consistent pressure on the lip, even when the rotating speed, temperature or load fluctuates, allowing the seal to perform reliably during continuous operation. The metal outer shell creates a precise interference fit in the housing, preventing the seal from rotating, shifting, or deforming during installation. This is essential in applications with tight tolerances or where temperature changes could expand the housing a bit. The reinforced metal cap makes the construction rigid and prevents deformation of the seal frame. This is important with larger diameters, higher radial loads or installations exposed to vibration. The integrated dust lip forms a second barrier which prevents external dirt, dust or moisture from reaching the main sealing lip. This ensures that the lubricating film keeps intact and it helps maintaining the sealing performance over longer service cycles, even when operating in environments that aren’t completely dry or clean.

The oil seal TA is used in applications where stability, oil retention and protection against contamination are simultaneously required. You’ll see these oil seals in gearboxes, reducers, industrial pumps, motors, agricultural machinery, construction equipment and other systems containing rotating shafts, operating under medium to heavy loads, especially when the operating environment isn’t completely clean or dry. The metal OD makes these seals suitable for metal housings where an elastomer OD doesn’t provide sufficient rigidity, compression or seating accuracy, such as in equipment that warms up, vibrates or runs continuously. The presence of a dust lip also makes the TA effective in systems exposed to dust, moisture, mud or other contaminants that would otherwise shorten the life of the primary sealing lip.

The TA oil seal stands out due to its rigid metal outer diameter, spring-supported sealing lip and integrated dust lip. Compared to rubber-OD variants, the TA maintains its shape more effectively during installation and does not deform when inserted into a tight metal housing, which is especially important where housings are thermally loaded or manufactured with tighter tolerances. The reinforced cap adds further stiffness for larger diameters and installations with fluctuating radial forces or long periods of high-speed operation.

The TA design can be combined effectively with other seal types when a system contains multiple sealing positions with different requirements. On positions where a rigid metal seating surface is needed, the TA is the appropriate choice, while at another point on the same shaft a TC rotary shaft seal may be used if a rubber-coated OD is preferred for compression and vibration damping. SA oil seal or SC oils seals may be selected for lighter or internally clean systems, as these require less structural stiffness. The oil seal TB is suitable when a rubber OD is preferred but a dust lip is still required, without the full rigidity of a metal OD. In this way, the TA can be integrated as part of a complete sealing strategy where each position is matched to the mechanical load and environmental conditions. The TA design is also more tolerant of imperfect or rough installation, maintaining lip stability even when mounting conditions are not ideal. For multi-layer sealing systems, the TA can be combined with Axial Seals AS-10 and V-rings to further improve contamination control.

There’s a variety of different manufacturers and supplies which all have different names or codes for this particular rotary shaft seal TA. Below is a cross-reference overview of all the different names/codes used by the various manufacturers and suppliers. This makes it easier to identify compatible replacements when working with mixed brands or older part numbers.

|

Manufacturer / Brand |

Code(s) / names for TA |

|

Dichtomatik |

WCS |

|

Anyseals |

OS-C11 |

|

B+S |

TR-F |

|

Chicago R |

CRWHA1 |

|

Elring |

CS |

|

Eriks |

GVST |

|

FP Paris |

L2P |

|

FST |

B2 SL |

|

Gaco |

– |

|

Goetze |

824 S |

|

Kaco |

DFSK |

|

Kramp |

DC |

|

National |

41 |

|

Paulstra |

CSEL |

|

Pioneer W |

– |

|

Rolf |

– |

|

Stefa |

DC |

|

Taiwan / NOK |

TA |

|

Vota |

B2 SL |

|

Ebele |

B2SL |

|

Kimman |

KCS |

When selecting the right oil seal TA, you must keep an eye on the shaft diameter, the housing dimensions and the tolerance class in which these components are manufactured. This is because an overly tight or loose fit directly affects the sealing pressure and overall stability. The operating temperature range determines the material choice. NBR is suitable for standard oils and normal temperatures, while FKM is required for higher temperature, higher rotating speeds or chemical aggressive media that could degrade some softer elastomers. Also shaft speed, environmental exposure, radial load and vibration must be evaluated, as these factors could influence the lip pressure and the rate of wear when the sealing lip is not supported enough. The TA oil seal operates within a typical temperature range of –40 °C to +100 °C, with a recommended limit of +80 °C when synthetic lubricants are used. The TA type is suitable for non-pressurised applications up to 0.05 MPa and should follow standard rotary shaft seal speed charts for maximum allowable shaft speeds. Compatibility testing is advised when using synthetic or specialised lubricants without proven application history.

The condition of the shaft surface is equally important; proper roughness, uniform hardness and a polished contact surface significantly extend seal life and prevent premature lip damage. Installation conditions must also be considered, since a metal-OD seal requires a rigid metal housing with the correct interference fit to prevent air leakage, micro-movement or rotation within the bore. An uneven or contaminated bore may cause misalignment and uneven lip pressure. Finally, installation angle, lubrication and correct tooling are essential to prevent lip damage during fitting and to ensure the interference fit is achieved correctly. The shaft should meet ISO h11 tolerances, have a minimum hardness of 45 HRC, and feature a lead-free finish with surface roughness values of Ra 0.2–0.8 µm, Rz 1–5 µm and Rmax ≤ 6.3 µm. The housing bore must follow ISO H8 tolerances and maintain surface roughness values within Ra 0.8–3.2 µm, Rz 6.3–16 µm and Rmax ≤ 16 µm to ensure a stable interference fit.

|

Material |

Temperature Range |

Media Resistance |

Properties |

|

NBR (Nitrile Rubber) |

-30 °C to +110 °C |

Standard oils, greases, mineral oils |

Good wear resistance, cost-effective, suitable for general industrial applications |

|

FKM (Fluoro Rubber) |

-20 °C to +200 °C |

High temperatures, aggressive oils, fuels, chemicals |

Excellent chemical resistance, low compression set, ideal for high-duty systems |

|

ACM (Acrylic Rubber) |

-20 °C to +150 °C |

Hot oils, ATF fluids |

Good heat and oxidation resistance, used in automotive applications |

|

EPDM |

-40 °C to +130 °C |

Water, steam, glycol fluids |

Not oil-resistant, excellent for water-based applications and weather/ozone exposure |

|

HNBR (Hydrogenated Nitrile) |

-30 °C to +150 °C |

Oils, fuels, refrigerants |

High mechanical strength and improved heat/chemical resistance compared to NBR |

|

VMQ (Silicone Rubber) |

-50 °C to +180 °C |

Mild oils, greases |

Very flexible at low temperatures, good thermal stability, lower wear resistance |

The spring element is typically made from spring steel according to DIN EN 10270-1, with stainless steel 1.4301 available for improved corrosion resistance. The metal case is produced from carbon steel (DIN EN 10139) as standard, with stainless steel 1.4301 available for harsh or corrosive environments.

A TA oil seal contains a fully metal outer diameter and a reinforced metal cap, whilst on the other hand, the TC seal has a rubber coated outer shell. This makes the TA type stiffer and more suitable for rigid metal housings, while the TC offers more compression and flexibility in less rigid housings.

You should choose for a metal-OD seal when the housing is fully made from metal, and the application requires a tight and stable fit which doesn’t deform during installation. This is especially important is systems with vibrations, higher radial loads or larger shaft diameters.

Yes, the TA design has an integrated dust lip that protects the primary sealing lip from dust, dirt and moisture, making it suitable for equipment operating in dirty or humid conditions.

The TA rotary shaft seal is available in NBR, FKM, VMQ, ACM, EPDM and HNBR. Each of these materials have their own strengths like heat resistance, wear resistance or low temperature flexibility.

Extremely important. The correct surface roughness, hardness and finish help to keep a steady lubrication film and reduce wear. A bad finishing of the shaft surface could lead to leakage, heat build-up and quicker degradation of the sealing lip.

Didn't find the right Oil Seal TA - Rotary Shaft Seal?

Complete the form below and we will help you!