| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

59763 | Oil Seal | 123.82 | 152.4 | 12.7 | VMQ - SILICONE | Steel | Steel | Yes | Yes | Red | 115 |

Request

|

Details | Quote | |

|

59762 | Oil Seal | 110 | 135 | 13 | VMQ - SILICONE | Steel | Steel | Yes | Yes | Red | 0 |

Request

|

Details | Quote | |

|

59761 | Oil Seal | 110 | 125 | 8 | ACM | Steel | Steel | Yes | Yes | Black | 216 |

Request

|

Details | Quote | |

|

61342 | Oil Seal | 710 | 760 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61341 | Oil Seal | 670 | 710 | 20 | FPM - VITON | Steel | Steel | Yes | Yes | Brown | 8 |

Request

|

Details | Quote | |

|

61339 | Oil Seal | 558.8 | 596.9 | 19.05 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 8 |

Request

|

Details | Quote | |

|

61338 | Oil Seal | 550 | 600 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61337 | Oil Seal | 550 | 590 | 20 | FPM - VITON | Steel | Steel | Yes | Yes | Brown | 0 |

Request

|

Details | Quote | |

|

61336 | Oil Seal | 550 | 590 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61335 | Oil Seal | 546.1 | 596.9 | 19.05 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61334 | Oil Seal | 540 | 590 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61333 | Oil Seal | 540 | 580 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61331 | Oil Seal | 533.4 | 584.2 | 22.22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61330 | Oil Seal | 530 | 580 | 25 | FPM - VITON | Steel | Steel | Yes | Yes | Brown | 0 |

Request

|

Details | Quote | |

|

61329 | Oil Seal | 520 | 570 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61328 | Oil Seal | 520 | 570 | 20 | FPM - VITON | Steel | Steel | Yes | Yes | Brown | 0 |

Request

|

Details | Quote | |

|

61327 | Oil Seal | 490 | 530 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61326 | Oil Seal | 467 | 510 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61325 | Oil Seal | 457.2 | 514.35 | 25.4 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61324 | Oil Seal | 445 | 480 | 16 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61323 | Oil Seal | 440 | 480 | 20 | FPM - VITON | Steel | Steel | Yes | Yes | Brown | 52 |

Request

|

Details | Quote | |

|

61321 | Oil Seal | 440 | 470 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61319 | Oil Seal | 430 | 480 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 40 |

Request

|

Details | Quote | |

|

61317 | Oil Seal | 410 | 470 | 25 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61316 | Oil Seal | 410 | 460 | 22 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61315 | Oil Seal | 406.4 | 444.5 | 17.47 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61314 | Oil Seal | 400 | 450 | 20 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61313 | Oil Seal | 400 | 440 | 18 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61312 | Oil Seal | 390 | 425 | 18 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote | |

|

61311 | Oil Seal | 385 | 430 | 30 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 |

Request

|

Details | Quote |

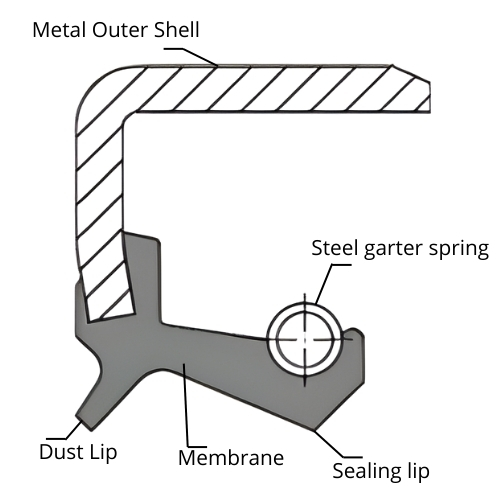

A TB oil seal is a type of radial shaft seal that incorporates a spring-loaded primary lip for retaining lubricant, a secondary dust lip to prevent contamination, and a metal outer shell for a reliable press-fit in the housing. The double-lip design makes the TB rotary shaft seal especially effective in dirty or outdoor environments. Compared to the oil seal TC, which has an elastomer outer diameter, the TB shaft seal is more suitable for housings with precise metal bores and where a metal-to-metal interference fit is preferred. In contrast to the oil seal SB, which includes a spring-loaded single lip without a dust lip, the oil seal TB provides enhanced sealing performance and high-end protection against external contaminants, making it more reliable for heavy-duty or outdoor applications.

The oil seal TB offers a variety of advantages. Besides the structural advantages, the rotary shaft seal provides operational reliability in rotating systems by preserving lubrication and preventing downtime. It’s double lip design ensures a consistent contact pressure over extended periods. In contaminated environments, the dust lip helps reduce internal wear by serving as the first barrier, keeping dust, dirt and moisture out.

This seal is typically made of NBR (nitrile elastomer), a material known for its durability, flexibility, and compatibility with mineral oil-based lubricants. For extremer conditions, it’s also available in FKM (Viton®), HNBR and other elastomers. The metal casing is produced in accordance with DIN EN 10139, and the spring element is manufactured from spring steel according to DIN EN 10270-1, with stainless steel options available for corrosive environments. Combined with options like bore sealant coatings or pairing with AS-10 axial seals and V-ring seals, the TB oil seal can be configured into a comprehensive sealing system for the most demanding environments. These design features not only protect internal components but also reduce bearing wear and overall maintenance cycles, making the TB seal a preferred solution across industries. The TB design is compatible with a wide range of shaft types and applications.

|

Lip Material |

Temp Range |

Properties |

|

NBR |

-40°C to +100°C |

Oil-resistant, flexible, cost-effective |

|

FKM (Viton®) |

-20°C to +200°C |

High temp and chemical resistance |

|

HNBR |

-30°C to +150°C |

Improved heat, oil, and wear resistance |

|

ACM |

-25°C to +150°C |

Excellent resistance to hot oil and oxidation |

|

EPDM |

-40°C to +140°C |

Strong resistance to water, steam, and some chemicals |

|

VMQ |

-60°C to +200°C |

Excellent low-temp flexibility, moderate oil resistance |

When selecting the right TB rotary shaft seal, it’s important to keep eye on some very important parameters. You must match the oil seal TB with the shaft diameter and housing bore tolerance, verify the temperature range based on the application, account for shaft speed and system pressure, and secure chemical compatibility with the fluid being sealed. The shaft should meet ISO H11 tolerance and have a minimum hardness of 45HRC to withstand wear, with surface roughness between Ra 0.2 - 0.8 µm and Rz 1 - 5 µm. The housing bore must comply with ISO H8 tolerance and present roughness values between Ra 0.8 – 3.2 2 µm to ensure a secure press-fit. Additionally, while the standard TB seal is compatible with mineral oil-based lubricants, alternative elastomers such as FKM or HNBR should be considered for applications involving synthetic lubricants or higher temperatures. Maximum allowable shaft speeds should be checked against standard rotary shaft seal performance charts for longevity and efficiency. By taking these parameters into account, engineers can ensure optimal sealing performance and extended service life.

TB oil seals are commonly used in gearboxes to retain lubricants and prevent dirt from entering, in electric motors to ensure lubricant containment and dust exclusion, and in pumps and compressors where dynamic sealing is essential. In agriculture and construction, oil seals TB protect vital components from mud, dust, and environmental exposure while withstanding mechanical loads.

There’s a variety of manufacturers and suppliers which all have their own names for the oil seal. In the table below you’ll find some of the most important ones, relevant to this particular oil seal TB design.

|

Brand / Standard |

Equivalent to TB |

|

Dichtomatik |

WBS |

|

Anyseals |

OS-B11 |

|

B+S |

TR-D |

|

Chicago R |

CRWA1 |

|

Elring |

BS |

|

Eriks |

MST |

|

FP Paris |

L1P |

|

FST |

B1 SL |

|

Goetze |

822 S |

|

Kaco |

DFS |

|

Kramp |

BC |

|

National |

47 |

|

Paulstra |

EEL |

|

Pioneer W |

R6 |

|

Stefa |

BC |

|

Taiwan / NOK |

TB |

|

Vota |

B1 SL |

|

Ebele |

B1SL |

|

Kimman |

KBS |

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

TB oil seals are commonly used in gearboxes, motors, pumps, and agricultural machinery. Their robust construction and dual-lip configuration make them ideal for dusty or wet conditions where reliable shaft sealing is essential.

Installation of an oil seal TB requires clean, burr-free shaft and housing surfaces. Align the seal carefully with the shaft axis and use even pressure to avoid distortion. Follow ISO tolerance standards for optimal fit and function.

Yes, but it's important to consult standard rotary shaft seal speed charts. Excessive speed can generate heat, which affects material selection (e.g., using FKM instead of NBR for better thermal resistance).

Yes, rotary oil seals with similar profiles and dimensions, such as CRWA1 or B1SL, can often serve as functional equivalents. However, always check cross-reference charts and application specs to ensure compatibility.

A metal-cased TB oil seal is more rigid and suitable for precise housing bores. It also performs better in environments with temperature fluctuations or mechanical vibration, where a stable fit is essential.

Didn't find the right Oil Seal TB - Rotary Shaft Seal?

Complete the form below and we will help you!