| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

51109 | Oil Seal | 95 | 120 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 1587 | € 13,12 | Details | ||

|

51082 | Oil Seal | 90 | 115 | 13 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 40,42 | Details | Quote | |

|

51067 | Oil Seal | 87.31 | 114.3 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 40,42 | Details | Quote | |

|

51058 | Oil Seal | 85 | 130 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 14,11 | Details | Quote | |

|

50971 | Oil Seal | 70 | 110 | 8 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 461 | € 11,48 | Details | ||

|

50916 | Oil Seal | 65 | 120 | 13 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 13,12 | Details | Quote | |

|

50910 | Oil Seal | 65 | 85 | 16 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 7,55 | Details | Quote | |

|

50853 | Oil Seal | 60 | 82 | 9 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 23,58 | Details | Quote | |

|

50851 | Oil Seal | 60 | 80 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 6,82 | Details | Quote | |

|

50754 | Oil Seal | 53 | 72 | 8 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 20,68 | Details | Quote | |

|

50753 | Oil Seal | 53 | 72 | 8 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 198 | € 6,52 | Details | ||

|

50727 | Oil Seal | 50.8 | 76.2 | 12.7 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 21,66 | Details | Quote | |

|

50500 | Oil Seal | 40 | 65 | 12 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 6,68 | Details | Quote | |

|

50496 | Oil Seal | 40 | 62 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 6,68 | Details | Quote | |

|

50480 | Oil Seal | 40 | 55 | 6 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 5,44 | Details | Quote | |

|

50477 | Oil Seal | 40 | 50 | 6.5 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 16,33 | Details | Quote | |

|

50463 | Oil Seal | 39 | 52 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 194 | € 5,47 | Details | ||

|

50436 | Oil Seal | 38 | 60 | 10 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 20,28 | Details | Quote | |

|

50239 | Oil Seal | 30 | 47 | 8 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 16,33 | Details | Quote | |

|

50229 | Oil Seal | 30 | 42 | 8 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 4,08 | Details | Quote | |

|

50130 | Oil Seal | 25 | 52 | 8 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 18,45 | Details | Quote | |

|

50111 | Oil Seal | 25 | 35 | 7 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 3,06 | Details | Quote | |

|

50049 | Oil Seal | 20 | 52 | 7 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 5,47 | Details | Quote | |

|

50047 | Oil Seal | 20 | 42 | 7 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 4,08 | Details | Quote | |

|

50038 | Oil Seal | 20 | 35 | 6 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 10,88 | Details | Quote | |

|

50016 | Oil Seal | 19 | 32 | 10 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 450 | € 3,06 | Details | ||

|

49949 | Oil Seal | 15 | 22 | 5 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 0 | € 9,45 | Details | Quote | |

|

49886 | Oil Seal | 6.35 | 19.05 | 6.35 | FPM - VITON | Steel | SS-304 | Yes | Yes | Brown | 1183 | € 9,45 | Details | ||

|

49885 | Oil Seal | 6 | 22 | 7 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 2,66 | Details | Quote | |

|

49880 | Oil Seal | 200 | 240 | 15 | NBR - Nitrile | Steel | Steel | Yes | Yes | Black | 0 | € 35,43 | Details | Quote |

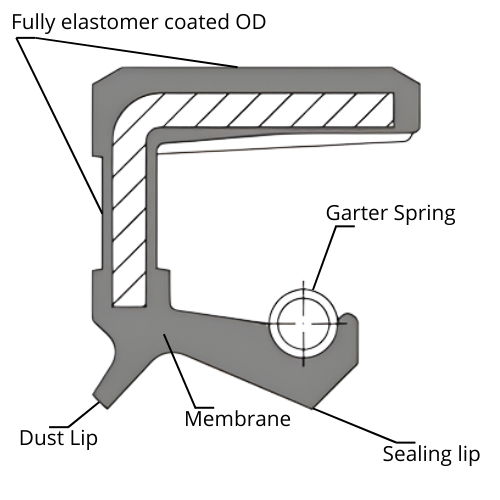

The TC Plus oil seal consists of a primary sealing lip supported by a stainless-steel garter spring. This lip retains oil, grease, or other lubricants inside the system. It also contains a second dust lip to prevent dirt, dust and moisture from entering. The fully elastomer coated metal reinforcement ring provides strength and corrosion resistance, while the rubber outer diameter ensures a safe, leak-free static seal against the housing.

During rotation, the main sealing lip glides over the shaft with a light, constant radial load. The spring ensures this contact is maintained even after wear or prolonged operation. The dust lip offers a second barrier to prevent external contamination. Together they maintain a long-term, reliable sealing solution in a variety of situations.

TC Plus oil seals show up in all kinds of equipment, from everyday machinery to the toughest industrial setups. You’ll see them in agricultural vehicles like tractors and harvesters, where seals have to deal with mud, vibration, and constant movement. In construction machines, think excavators, wheel loaders, hydraulic motors, they handle heavy loads and dirty environments without losing sealing performance.

They’re just as common in industrial drive systems. Gearboxes, pumps, compressors etc. all rely on stable sealing, especially when temperatures rise or the machine runs for long periods. The automotive world uses them too: crankshafts, differentials, driveshaft assemblies, anywhere a reliable double-lip seal is needed.

Electric motors and generators benefit from the TC Plus design as well. These seals help keep moisture and dust out of the bearing housings, which makes a big difference in long-term reliability. And in the marine and energy sectors, turbines, propulsion systems, industrial fans, the TC Plus holds up impressively under constant load, varying conditions, and exposure to chemicals or humidity.

The choice in material largely determines the chemical resistance, temperature tolerance, and overall lifespan of the sealing. Each kind of elastomer has a unique property that make it suitable for specific applications. FKM is often used because of its excellent resistance to heat and chemicals. While NBR is mostly used because it is the most economical and versatile choice for standard oil lubrication. Silicone remains really flexible at low temperatures, HNBR offers improved wear resistance and mechanical strength, ACM performs well in hot oils, EPDM is ideal for water and steam environments, and CR is selected for applications requiring weather resistance and flame retardancy. Selecting the right material prevents premature wear, hardening, or swelling of the sealing lip and directly contributes to stable, leak-free performance.

|

Material |

Temperature Range |

Properties |

|

NBR |

-40°C to +100°C |

Good oil and grease resistance, flexible, economical, suitable for general applications |

|

FKM (Viton®) |

-25°C to +200°C |

Excellent chemical resistance, high temperature stability, suitable for heavy industrial conditions |

|

Silicone (VMQ) |

-60°C to +150°C |

Highly flexible at low temperatures, good resistance to thermal fluctuations |

|

ACM |

-20°C to +150°C |

Resistant to hot oils and ATF, commonly used in automotive applications |

|

HNBR |

-30°C to +150°C |

High wear resistance, strong mechanical properties, improved heat and ozone resistance |

|

CR |

-40°C to +100°C |

Good weather, ozone, and flame resistance, moderate oil resistance |

|

EPDM |

-40°C to +120°C |

Excellent resistance to hot water, steam, and brake fluids, not suitable for mineral oils |

The TC Plus oil seal is an optimized version of the standard TC oil seal. Where a TC oil seal normally uses NBR and a steel garter spring, the TC plus oil seal used FKM more often in combination with a stainless-steel garter spring. This rotary shaft seal TC plus is also completely covered in elastomer unlike the standard oil seal TC. This makes the TC plus oil seal much better resistant to heat, chemicals and corrosion.

The SC plus oil seal also looks a lot like the TC plus oil seal but this one has just one main sealing lip (without da dust lip) and is designed to operate in low- to non-contaminated environments. The TC Plus provides two sealing lips and is better suited for applications exposed to external contamination.

When choosing the right TC plus oil seal you should take a variety of factors into account. Think of medium types, like oil, grease, fuels, steam, or chemicals, as the correct material is essential to withstand these mediums. For example, FKM works well for applications containing fuel or high temperatures. Also, the minimum and maximum operating temperature are important, just like the rotating speed of the shaft. Environmental influences like dirt, moisture, mud, dust or UV also play a large role in choosing the right material and design. You also have to look at the condition of the shaft and the housing surfaces: if they are rough or subject to thermal expansion, a rubber-covered outer diameter offers better reliability. At last, the TC plus oil seal has to fit properly in both diameter and depth of the bore and needs to be installed the right way with the proper orientation.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The TC Plus uses superior materials (such as Viton and stainless steel) and has a fully rubber-encapsulated reinforcement ring, making it far more resistant to heat, chemicals, and corrosion.

No. Standard TC Plus seals are not designed for pressures above 0.05 MPa. For high-pressure applications, TCN or PTFE-based seals are required.

Agricultural machinery, construction equipment, industrial pumps, motors, gearboxes, and transport applications where contamination, moisture, and high temperatures are common.

That depends on temperature, medium, and environment. NBR is standard, FKM is for heat and chemicals, HNBR is for wear resistance, and Silicone is for low-temperature conditions.

Didn't find the right Oil Seal TC Plus - Rotary Shaft Seal?

Complete the form below and we will help you!