| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

76384 | Oil Seal | 8 | 20 | 6 | NBR - Nitrile | Yes | Yes | Black | 159 | € 2,65 | Details | ||

|

76387 | Oil Seal | 40 | 56 | 8 | FPM - VITON | Yes | Yes | Brown | 958 | € 20,28 | Details | ||

|

76391 | Oil Seal | 80 | 100 | 10 | NBR - Nitrile | Yes | Yes | Blue | 993 | € 9,64 | Details | ||

|

76392 | Oil Seal | 80 | 105 | 7 | FPM - VITON | Yes | Yes | Brown | 114 | € 34,48 | Details | ||

|

76393 | Oil Seal | 80 | 105 | 7 | NBR - Nitrile | Yes | Yes | Blue | 366 | € 10,43 | Details | ||

|

76396 | Oil Seal | 80 | 110 | 10 | FPM - VITON | Yes | Yes | Brown | 109 | € 36,68 | Details | ||

|

76436 | Oil Seal | 85 | 100 | 10 | FPM - VITON | Yes | Yes | Brown | 541 | € 31,08 | Details | ||

|

76437 | Oil Seal | 85 | 100 | 10 | NBR - Nitrile | Yes | Yes | Black | 1469 | € 9,64 | Details | ||

|

76442 | Oil Seal | 85 | 105 | 12 | NBR - Nitrile | Yes | Yes | Black | 600 | € 10,42 | Details | ||

|

76443 | Oil Seal | 85 | 105 | 7 | FPM - VITON | Yes | Yes | Brown | 576 | € 34,48 | Details | ||

|

76444 | Oil Seal | 85 | 105 | 7 | NBR - Nitrile | Yes | Yes | Black | 1376 | € 10,42 | Details | ||

|

76447 | Oil Seal | 85 | 110 | 12 | NBR - Nitrile | Yes | Yes | Black | 5 | € 11,48 | Details | ||

|

76452 | Oil Seal | 85 | 120 | 7 | NBR - Nitrile | Yes | Yes | Black | 369 | € 13,12 | Details | ||

|

76489 | Oil Seal | 45 | 62 | 7 | FPM - VITON | Yes | Yes | Brown | 0 | € 22,68 | Details | Quote | |

|

76493 | Oil Seal | 90 | 110 | 7 | FPM - VITON | Yes | Yes | Brown | 586 | € 36,68 | Details | ||

|

76494 | Oil Seal | 90 | 110 | 7 | NBR - Nitrile | Yes | Yes | Black | 458 | € 11,48 | Details | ||

|

76497 | Oil Seal | 90 | 115 | 10 | NBR - Nitrile | Yes | Yes | Black | 365 | € 12,24 | Details | ||

|

76517 | Oil Seal | 95 | 115 | 12 | FPM - VITON | Yes | Yes | Brown | 300 | € 40,42 | Details | ||

|

76518 | Oil Seal | 95 | 115 | 12 | NBR - Nitrile | Yes | Yes | Black | 190 | € 12,24 | Details | ||

|

76545 | Oil Seal | 28.57 | 48 | 6 | NBR - Nitrile | Yes | Yes | Black | 770 |

Request

|

Details | Quote | |

|

76564 | Oil Seal | 28.57 | 50.8 | 6.35 | NBR - Nitrile | Yes | Yes | Black | 1399 | € 5,47 | Details | ||

|

77117 | Oil Seal | 25.4 | 38.1 | 6.35 | NBR - Nitrile | Yes | Yes | Black | 740 | € 3,57 | Details | ||

|

80061 | 19,05 | 30,16 | 6,35 | NBR - Nitrile | Yes | Yes | Black | 14 | € 2,96 | Details |

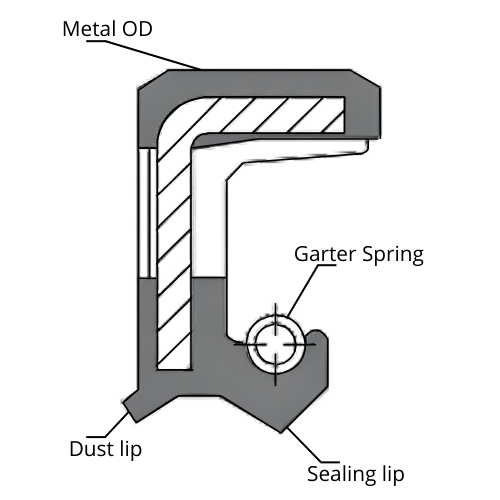

The pressure resistance of a TCN oil seal does not rely on additional components, but on the geometry of the sealing lip. This design is commonly referred to as a pressure-loadable sealing lip, indicating that the lip geometry is specifically intended to remain stable under internal system pressure. The short primary lip, supported by a garter spring, is designed to remain axially and radially stable as internal pressure increases and is less prone to overturning than the longer lip of a standard TC oil seal. As a result, the contact line between the lip and the shaft remains controlled and reproducible, preventing leakage without unnecessarily increasing the sealing force.

The spring provides a constant base load on the lip, independent of minor wear or dimensional tolerances, while the short lip length limits the influence of pressure and temperature on lip deformation. This makes the oil seal TCN suitable for sealing both viscous and low-viscosity media, and in specific cases even gaseous media, provided that rotational speed and heat generation remain within permissible limits.

The secondary dust lip has no pressure-sealing function but serves a protective role by keeping external contaminants away from the sealing zone. This reduces abrasive wear of the primary lip and contributes to stable sealing performance over the long term. The fully elastomer-coated outer diameter, executed with a smooth surface, simultaneously ensures reliable static sealing in the housing. This outer diameter also prevents fretting corrosion between the seal and the housing, which is especially relevant in aluminum and split housings. This allows the seal to perform reliably in housings with thermal expansion, increased surface roughness or split constructions, without the risk of fretting corrosion or micro-leakage along the outer diameter.

TCN oil seals are used in rotating systems with internal pressure, such as hydraulic pumps, hydraulic motors and other pressure-loaded units. Typical examples include gear pumps, vane pumps and orbit motors, where the shaft seal is directly exposed to system pressure and where a standard TC oil seal does not provide sufficient sealing reliability. TCN oil seals are also commonly used in compact hydraulic units, power packs and mobile machinery, as they provide pressure-resistant sealing without requiring additional installation space.

In addition, TCN oil seals are applied in industrial drives and transmissions in which local pressure build-up may occur, for example due to limited venting or temperature increase. In such situations, the stable lip design prevents oil or low-viscosity lubricants from being forced out along the shaft. The combination of pressure resistance, double-lip sealing and an elastomer-coated outer diameter also makes the oil seal TCN suitable for aluminum or split housings, such as those commonly found in refurbished pumps and motors.

At the same time, the oil seal TCN is not a universal solution. At high rotational speeds, the permissible pressure decreases rapidly, making this type unsuitable for fast-running shafts or applications in which pressure and speed are simultaneously high, such as high-speed spindles or turbomachinery. In those cases, other sealing concepts, such as cassette seals or mechanical seals, are required to ensure reliable sealing.

Although the construction of a TCN oil seal is fixed, the elastomer material largely determines its suitability for a given application. For the standard NBR material combination, the typical operating temperature range is −30 °C to +100 °C, with a recommended maximum of 80 °C when synthetic lubricants are used to ensure long service life. NBR is the standard material and is suitable for mineral oils and general hydraulic applications. It offers good wear resistance but has a limited temperature range.

FKM is selected when temperature or chemical exposure is higher. This material remains stable at elevated temperatures and in more aggressive media but comes at a higher cost.

HNBR represents an intermediate solution with improved mechanical properties compared to NBR.

Other elastomers such as ACM, EPDM, CR or silicone are only used when specific media or temperature requirements make them necessary. When synthetic lubricants are used for which no field experience is available, compatibility should be verified through testing, preferably under practical operating conditions.

The spring and reinforcing ring can also be supplied in stainless steel when corrosion resistance is required.

|

Material |

Typical temperature range |

Key properties |

|

NBR (Nitrile Rubber) |

−30 °C to +100 °C(recommended max. 80 °C with synthetic oils) |

Good wear resistance, suitable for mineral oils and greases, cost-effective, limited heat and chemical resistance |

|

FKM (Viton®) |

−20 °C to +180 °C |

Excellent heat resistance, good chemical resistance, suitable for synthetic oils, higher cost |

|

HNBR |

−30 °C to +150 °C |

Improved mechanical strength, better pressure and wear resistance than NBR, limited chemical resistance compared to FKM |

|

ACM |

−20 °C to +150 °C |

Good resistance to hot oils and oxidation, moderate low-temperature performance |

|

CR (Neoprene) |

−30 °C to +120 °C |

Balanced oil and weather resistance, moderate mechanical properties |

|

EPDM |

−40 °C to +150 °C |

Excellent resistance to water, steam and brake fluids, not suitable for mineral oils |

|

Silicone (VMQ) |

−60 °C to +200 °C |

Very wide temperature range, good flexibility at low temperatures, low wear resistance and limited pressure capability |

In practice, a TCN oil seal is often compared to a standard TC oil seal, as their basic construction with a double-lip design is similar. The key difference lies in the intended application: an oil seal TC is designed for rotary sealing in pressure-free or splash-lubricated environments, whereas an oil seal TCN features a pressure-loadable sealing lip and is explicitly intended for applications with internal system pressure, such as hydraulic pumps and motors.

Compared to metal outer diameter oil seals, such as the oil seal TB, the oil seal TCN is more tolerant of housing variations, surface roughness and thermal expansion, particularly in aluminum or split housings. Within the range of elastomer-based rotary shaft seals, the TCN rotary shaft seal therefore occupies a clearly defined position for applications where internal pressure is present but a compact, standardised oil seal solution is required.

Selecting a TCN oil seal starts with the nominal dimensions of the shaft and housing but is ultimately determined by the operating conditions. For reliable sealing, the shaft must comply with ISO h11 tolerances, have a torsion-free surface and sufficient hardness, while the housing is typically manufactured to ISO H8 tolerances. The shaft surface should typically have a roughness of Ra 0.2–0.8 µm with a lead-free finish, while the housing bore may have a roughness of Ra 1.6–6.3 µm to ensure reliable static sealing.

Equally important is the combination of rotational speed and pressure. At low speeds, a TCN type can seal several bar of pressure; at higher speeds, this capacity decreases significantly. Heat dissipation, lubrication and media compatibility also play an important role. The correct selection therefore does not depend on a single parameter, but on the interaction between geometry, material and application.

| Rotational speed (rpm) | Shaft Ø 20 mm | Shaft Ø 40 mm | Shaft Ø 80 mm |

|---|---|---|---|

| 0 | 10.0 | 8.5 | 7.0 |

| 500 | 10.0 | 8.5 | 5.0 |

| 1000 | 5.5 | 4.5 | 3.0 |

| 2000 | 3.0 | 2.5 | 1.5 |

| 3000 | 2.0 | 1.5 | 0.3 |

| 4000 | 1.2 | 0.5 | 0.0 |

| 5000 | 0.7 | 0.0 | — |

| 6000 | 0.0 | — | — |

When replacing or specifying an oil seal TCN, different manufacturers may use alternative designations for the same pressure-loadable seal design, as shown in the cross-reference table below.

|

Manufacturer |

High pressure oil seal (TCN equivalent) |

|

Dichtomatik |

WASY |

|

Anyseals |

OS-N11 |

|

B+S |

TR-U |

|

Eriks |

RST-D |

|

FP Paris |

GAP |

|

FST |

BAB SL |

|

Goetze |

827 SK |

|

Kaco |

DGSP |

|

Kramp |

BABSL |

|

Stefa |

CF |

|

Taiwan / NOK |

TCV / TCN |

|

Vota |

BAB SL |

|

Kimman |

KAS-P |

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

When internal pressure is present and a standard TC oil seal does not provide sufficient sealing.

Yes, provided that rotational speed, shaft diameter and heat dissipation remain within the specified limits.

No, at high rotational speeds the pressure capacity decreases significantly.

Yes, at low pressure and low speed this is possible due to the stable lip design.

Yes, the elastomer-coated outer diameter makes them particularly suitable for this type of housing.

Didn't find the right Oil Seal TCN - Pressure Rotary Shaft Seal?

Complete the form below and we will help you!