| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

54587 | Oil Seal | 15 | 25 | 4 | FPM - VITON | Steel | Brown | 0 |

Request

|

Details | Quote | |

|

54583 | Oil Seal | 53.5 | 90 | 6 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

54572 | Oil Seal | 35 | 43 | 4 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

54568 | Oil Seal | 22.9 | 40 | 5 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

54567 | Oil Seal | 28.5 | 52 | 5 | NBR - Nitrile | Steel | Black | 908 | € 1,96 | Details | ||

|

54566 | Oil Seal | 17 | 35 | 5 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

54558 | Oil Seal | 20 | 28 | 4.5 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

54553 | Oil Seal | 20 | 28 | 4 | NBR - Nitrile | Steel | Black | 23925 | € 2,41 | Details | ||

|

54552 | Oil Seal | 20 | 26 | 4 | FPM - VITON | Steel | Brown | 0 |

Request

|

Details | Quote | |

|

54548 | Oil Seal | 120 | 135 | 7 | NBR - Nitrile | Steel | Black | 399 | € 15,02 | Details | ||

|

53419 | Oil Seal | 15.87 | 20.63 | 2.38 | NBR - Nitrile | Steel | Black | 519 | € 1,40 | Details | ||

|

53352 | Oil Seal | 25 | 32 | 4 | FPM - VITON | Steel | Brown | 0 |

Request

|

Details | Quote | |

|

53308 | Oil Seal | 20 | 26 | 2 | NBR - Nitrile | Steel | Black | 0 |

Request

|

Details | Quote | |

|

52853 | Oil Seal | 40 | 47 | 4 | FPM - VITON | Steel | Brown | 0 |

Request

|

Details | Quote |

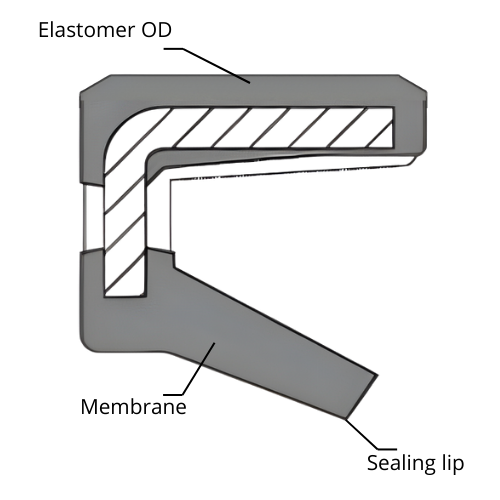

The VC rotary shaft seal uses a form-pressed sealing lip to keep a consistent pressure on the rotating shaft. Because there’s no radial spring this sealing is best suitable for applications with low friction and limited heating. The sealing lip prevents oil or grease from escaping, while the outer diameter provides static sealing within the bore. The soft elastomer outer diameter allows the seal to compensate for minor bore imperfections, making it suitable for housings with increased surface roughness or slight thermal expansion.

The entire elastomer construction offers installation advantages: the seal presses easily into place, absorbs minor vibration, and adapts well to housings with standard tolerances. That’s why the oil seal VC type is especially suited for applications where there’s limited space, cost efficiency is important, and a spring-loaded lip is not required. The temperature stability, chemical resistance and lifespan of the oil seal depends on the material. This allows the VC seal to be matched to various operating environments, from general machinery to applications with temperature fluctuations or specific media conditions. Because the lip is not spring-loaded, wear on both the lip and the shaft surface is reduced, which contributes to longer service life in low-duty applications.

De VC rotary shaft seal consists of one main sealing lip and an elastomer outer shell. The lip operates without a garter spring and relies its elastic recovery to keep radial pressure on the rotating shaft. The outer diameter of the oil seal provides a reliable press-fit and minimizes leakage between the seal and housing.

Unlike metal-cased or reinforced designs (such as the SA type oil seal), the VC oil seal is made for applications where load, flexibility and complex installation access are moderate. This makes the oil seal VC particularly suitable for retrofits and standard industrial rotating shafts. For housings that require improved bore retention, the oil seal G12 type with a ribbed outer diameter provides additional grip and stability while maintaining the same basic sealing principle.

|

Material |

Key Properties |

Indicative Temperature Range |

Typical Use Cases |

|

NBR (Nitrile Rubber) |

Excellent oil and grease resistance, good wear resistance, economical |

-30 °C to +100 °C |

General machinery, gearboxes, pumps, light transmissions |

|

FKM (Viton®/Fluoroelastomer) |

High heat resistance, excellent chemical resistance |

-20 °C to +200 °C |

Automotive, drive systems, chemical media, synthetic lubricants |

|

ACM (Polyacrylate) |

Good heat and oxidation resistance |

-20 °C to +150 °C |

Automotive applications, higher oil temperatures |

|

EPDM |

Excellent resistance to water, steam, coolants; not compatible with oil |

-40 °C to +140 °C |

HVAC, steam systems, coolant applications |

|

VMQ (Silicone) |

Outstanding low-temperature flexibility, broad temperature range |

-60 °C to +200 °C |

Extreme cold or heat, low mechanical load applications |

The oil seal VC performs best in depressurised applications and at low to medium rotary speed. Because it’s doesn’t have a spring-loaded sealing lip the sealing pressure is less high than oil seals which do have a spring-loaded sealing lip. This results in reduced wear and less frictional heat. The VC type is suitable for shaft speeds up to approximately 6 m/s, depending on size and material, in line with standard rotary shaft seal performance charts. The temperature range and the chemical compatibility depend on the chosen material. For higher temperatures and synthetic lubricants, FKM is usually the preferred material, while on the other hand NBR is an excellent choice when using mineral oils.

For an oil seal to be reliable, the rotating shaft and housing must meet standard tolerances. The shaft should be free of burrs and have an appropriate surface finish, and the lip should be slightly lubricated with a compatible grease or oil before installation. For optimal performance, the shaft should have a minimum hardness of 45 HRC to prevent premature groove formation. The seal should be pressed straight into the bore without tilting. An installation tool prevents the oil seal VC from getting damaged or deformed. Because the VC is made of elastomer, it tolerates minor housing deviations better than metal-cased designs. However, correct alignment and surface preparation remain essential for long service life.

The VC rotary shaft seal is used in a wide variety of industries, including machinery, workshop equipment, HVAC systems, small motors, fans, pumps, and basic drive assemblies. Thanks to the different material options this oil seal can be used in greasy, dry, and lightly humid environments.

Because there's a lot of different brands/suppliers, these sealings go under a variety of names/codes. The table underneath shows a selection of brands/suppliers and their corosponding codes.

| Brand / Supplier | Cross-Reference Code |

|---|---|

| Dichtomatik | WAO |

| Anyseals | OS-A12 |

| B+S | TR-K |

| Elring | A OF |

| Eriks | RZV |

| FP Paris | GSM |

| FST | BA OF |

| Gaco | SA |

| Goetze | 827 NO |

| Kaco | DE |

| Kramp | CD |

| Paulstra | IO |

| Pioneer W | R26 |

| Rolf | LSM |

| Stefa | CD |

| Taiwan / NOK | VC |

| Vota | BA OF |

| Ebele | RZV |

| Kimman | KAOW |

Choose the VC type when:

DON’T choose the VC type when:

In such cases, KC (with dust lip) or SC (spring-loaded) are better choices. And you might even consider the TC which has a spring-loaded sealing lip as wel as a secundairy dust lip to keep out contaminents.

|

Property |

VC |

SC |

KC |

|

Number of lips |

1 (single main lip) |

1 (single spring-loaded lip) |

2 (main sealing lip + additional dust lip) |

|

Garter spring |

No (non-spring-loaded lip) |

Yes (spring-loaded elastomer lip) |

No (non-spring-loaded main lip) |

|

Outer diameter |

Elastomer-coated metal case |

Elastomer-coated metal case |

Elastomer-coated metal case |

|

Sealing force |

Low–medium (secondary, low-friction sealing) |

Medium–high (spring-loaded primary sealing) |

Low–medium (secondary sealing with dust exclusion) |

|

Contamination resistance |

Light (no dust lip, secondary grease sealing) |

Light–medium (clean, enclosed systems, no dust lip) |

Medium–high (extra dust lip for external contaminants) |

|

Typical use |

Compact secondary seal for grease retention in confined assemblies |

Primary shaft seal in clean, enclosed systems (motors, pumps, gearboxes) |

Compact secondary seal with dust lip for grease retention in slightly contaminated environments |

|

Installation robustness |

High (tolerant of rougher/expanding housings) |

Medium–high (standard elastomer OD, spring-sensitive lip) |

High (like VC; compact, elastomer-coated OD) |

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The oil seal VC type has one non-spring-loaded sealing lip.

When low friction is desired and the application does not involve high pressure or heavy dynamic loads.

Yes, if made from compatible materials like FKM.

VC is a single non-spring-loaded sealing. The KC oil seal is almost the same but with an added dust lip. The oil seal SC is also comparable to the VC type seal but that one has a spring-loaded main lip.

Didn't find the right Oil Seal VC - Rotary Shaft Seal?

Complete the form below and we will help you!