| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

71185 | Oil Seal | 35 | 50 | 8 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71184 | Oil Seal | 65 | 88 | 12 | NBR - Nitrile | Steel | No | No | Green | 0 | € 2,65 | Details | Quote | |

|

71183 | Oil Seal | 65 | 88 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 2,65 | Details | Quote | |

|

71182 | Oil Seal | 70 | 95 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 2,93 | Details | Quote | |

|

71181 | Oil Seal | 35 | 50 | 5 | NBR - Nitrile | Steel | No | No | Green | 1213 | € 1,49 | Details | ||

|

71180 | Oil Seal | 35 | 50 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71179 | Oil Seal | 35 | 47 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71178 | Oil Seal | 35 | 43 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,28 | Details | Quote | |

|

71177 | Oil Seal | 35 | 40 | 5 | NBR - Nitrile | Steel | No | No | Green | 1704 | € 1,17 | Details | ||

|

71176 | Oil Seal | 33 | 47.5 | 9.1 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71175 | Oil Seal | 33 | 42 | 5 | NBR - Nitrile | Steel | No | No | Green | 1464 | € 1,28 | Details | ||

|

71174 | Oil Seal | 31.7 | 38.1 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71173 | Oil Seal | 31 | 38.5 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71172 | Oil Seal | 30 | 50 | 5 | NBR - Nitrile | Steel | No | No | Green | 1288 | € 1,49 | Details | ||

|

71171 | Oil Seal | 30 | 42 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,28 | Details | Quote | |

|

71170 | Oil Seal | 30 | 40 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71169 | Oil Seal | 29 | 40.5 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,28 | Details | Quote | |

|

71168 | Oil Seal | 29 | 39 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71167 | Oil Seal | 29 | 35 | 3.5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,03 | Details | Quote | |

|

71166 | Oil Seal | 28 | 38 | 7 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71165 | Oil Seal | 28 | 35 | 7 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,03 | Details | Quote | |

|

71164 | Oil Seal | 28 | 34 | 4 | NBR - Nitrile | Steel | No | No | Green | 890 | € 1,03 | Details | ||

|

71163 | Oil Seal | 27 | 43 | 9 | NBR - Nitrile | Steel | No | No | Green | 915 | € 1,28 | Details | ||

|

71162 | Oil Seal | 27 | 37 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71161 | Oil Seal | 27 | 36 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,17 | Details | Quote | |

|

71160 | Oil Seal | 27 | 33.7 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,03 | Details | Quote | |

|

71159 | Oil Seal | 27 | 35.5 | 5 | NBR - Nitrile | Steel | No | No | Green | 697 | € 1,17 | Details | ||

|

71158 | Oil Seal | 25 | 47 | 6 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71157 | Oil Seal | 25 | 47 | 5 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,49 | Details | Quote | |

|

71156 | Oil Seal | 25 | 45 | 4 | NBR - Nitrile | Steel | No | No | Green | 0 | € 1,28 | Details | Quote |

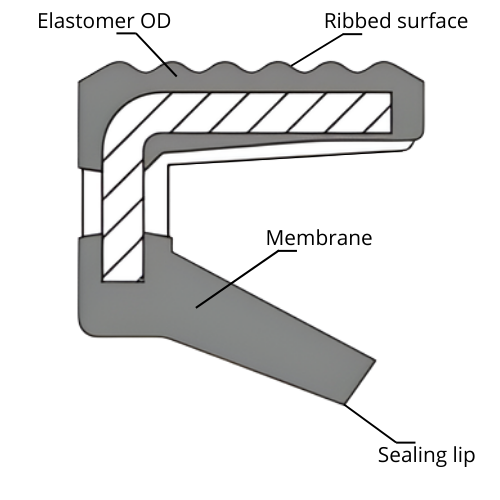

Inside the VG oil seal lies a steel reinforcement ring, which provides structural stability and is fully encapsulated within the elastomer. The outer diameter of the seal is also coated with elastomer and features a ribbed surface. These ribs allow the seal to adapt to housings with increased surface roughness, to compensate for expansion in light-metal housings and to seat securely in split housings without the risk of leakage.

The sealing lip itself contains no garter spring. Instead, it relies entirely on the elasticity of the elastomer to generate the radial contact pressure required to retain grease or oil. The springless design lowers friction significantly, which reduces heat generation and wear during operating hours. This makes the oil seal VG type a suitable solution for lubrication tasks which don’t use high pressures. Its elastomer outer diameter prevents fitting corrosion and enables safe static sealing even in housings that do not meet ideal surface conditions.

During operation time the sealing lip maintains a stable and controlled contact with the rotating shaft. Because the VG oil seal is designed for pressure less media, it performs best in combination with lubricants which stay within the thermal and chemical limits of the material. With correct alignment, lubrication and installation, the VG oil seal provides consistent performance and long service life in demanding mechanical environments.

The VG oil seal is intended for supportive or secondary sealing tasks where pressure is absent, and lubrication must be reliably maintained. It is frequently used in general machine and equipment construction, particularly in assemblies where a compact sealing solution is necessary. Because the elastomer-coated OD compensates for rough housings, split housings and thermally active structures, the VG type is especially well suited to light-metal housings commonly found in modern mechanical systems.

In drive technology, the VG seal performs well in grease-lubricated components such as small gear mechanisms, bearing housings and auxiliary drives. Its low-friction behavior also makes it a practical choice for electric motors, where efficient running and controlled heat development are critical. The VG type represents a dependable sealing option wherever a minimalistic, low-wear and space-efficient solution is required.

The standard VG oil seal is made of green NBR 70. This is a robust elastomer which is suitable for mineral oils, grease and many synthetic lubricants. The internal reinforcement ring is made of sheet steel according to DIN EN 10139, ensuring dimensional stability during installation and operation.

For applications requiring enhanced thermal, chemical or mechanical resistance, the VG rotary shaft seal is also available in several special elastomers. This includes: FKM for applications with high temperatures or chemically aggressive oils, silicones for extremely low temperature environments, ACM for applications with exposure to motor oils, HNBR for heavy mechanical loads and raised temperatures, CR for situations with exposure to weather and ozone, and EPDM for environments with water, steam or glycol-based liquids.

Below is an overview of the material options and their performance characteristics.

|

Material |

Typical Use Case |

Key Advantages |

|

NBR 70 (Standard) |

General grease/oil sealing up to 100°C |

Excellent elasticity, cost-effective, suitable for most mineral and synthetic lubricants |

|

FKM |

High-temperature or chemically aggressive lubricants |

Outstanding heat and chemical resistance |

|

Silicone (VMQ) |

Low-temperature or thermally fluctuating applications |

Exceptional flexibility at extreme temperatures |

|

ACM |

Lubrication systems involving engine oils and oxidation-prone environments |

Strong resistance to heat and oil degradation |

|

HNBR |

Mechanically demanding applications with elevated temperatures |

High mechanical strength and improved chemical resistance |

|

CR |

Outdoor or weather-exposed machinery |

Good ozone and weathering resistance |

|

EPDM |

Environments involving water, steam or brake fluids |

Excellent resistance to non-oil media (not suitable for oil) |

Within the same product family, the oil seal VG, the oil seal KG and VC oil seals share the same basic springless lip design, but differ in how they interact with the housing and the environment. The VG oil seal type uses a ribbed elastomer-coated outer diameter without a dust lip, making it ideal for grease and oil sealing in clean, pressureless applications where low friction, compact design and good compensation for housing roughness or thermal expansion are important. The oil seal VC type has the same sealing lip geometry as the oil seal VG, but features a smooth elastomer outer diameter instead of a ribbed one. This makes the VC oil seals suitable for housings with more consistent surface quality and tighter machining, where less deformation of the OD is required. The rotary shaft seal KG type is, in essence, a VG seal with an additional dust lip: it keeps the same ribbed elastomer OD and springless sealing lip, but adds extra protection against contamination from the outside. As a result, the VG oil seal is typically chosen for internal, cleaner environments with minimal external dirt, KG for applications where dust or particles are present, and VC where a smooth elastomer OD is preferred due to housing design or manufacturing conditions.

Choosing the right VG oil seal requires attention to both material properties and mechanical tolerances. The oil seal VG can’t be used in the hydraulic of pneumatic systems because it’s designed for pressure less systems. Its maximum allowable circumferential speed is 6 m/s, and the standard NBR version operates reliably between –40°C and +100°C. When synthetic lubricants are used for the first time, the compatibility must be verified through laboratory of practical testing. In this case the temperature can’t reach higher than 80°C. The performance of the VG oil seal depends strongly on the correct shaft- and housing conditions. The shaft must match ISO h11 tolerances, be hardened to at least 45 HRC and feature a torsion-free surface with a roughness between Ra 0.2 and 0.8 μm. The housing must match the ISO H8 tolerance and may have a rougher surface, as the ribbed elastomer outer diameter compensates for irregularities. Proper installation is essential for long-term performance, and the manufacturer’s installation guidelines should always be followed to avoid damage during assembly.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

The ribbed OD improves static sealing, compensates for thermal expansion and allows installation in rough or split housings.

Yes. Its ability to adapt to thermal expansion makes it especially suitable for aluminium and other light-metal housings.

For NBR 70, the operating temperature range is –40°C to +100°C. For synthetic lubricants without prior application data, the temperature should not exceed 80°C.

The maximum circumferential speed is 6 m/s under correct lubrication and shaft surface conditions.

The shaft must meet ISO h11 tolerances, have a minimum hardness of 45 HRC and a surface finish of Ra 0.2–0.8 μm.

Didn't find the right Oil Seal VG - Rotary Shaft Seal?

Complete the form below and we will help you!