| Product | Product Id | Type | Height | Inside Diameter | Outer Diameter | Material | Housing Material | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

26213 | Axial Seal | 5.5 | 85 | 107 | NBR - Nitrile | Steel | Black | 26 | € 15,71 | Details | |

|

26212 | Axial Seal | 5.5 | 75 | 97 | NBR - Nitrile | Steel | Black | 14 | € 13,76 | Details | |

|

26211 | Axial Seal | 4 | 25 | 42 | NBR - Nitrile | Steel | Black | 575 | € 6,53 | Details | |

|

26210 | Axial Seal | 4 | 20 | 37 | NBR - Nitrile | Steel | Black | 73 | € 5,70 | Details | |

|

26209 | Axial Seal | 4 | 17 | 34 | NBR - Nitrile | Steel | Black | 542 | € 5,70 | Details |

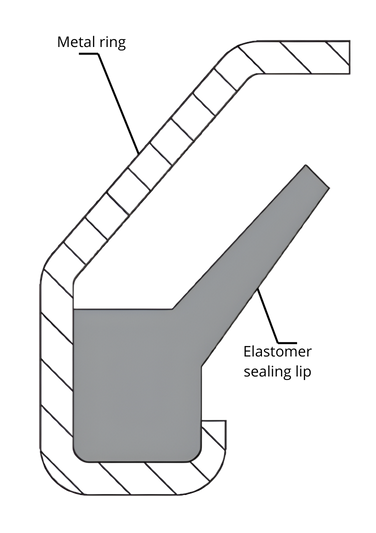

The AS-11 axial seal contains a metal outer casing with a vulcanized elastomer sealing element which is typically made of NBR or FKM. The metal ring is typically formed from sheet steel to JIS G3141 SPCC (comparable to 1.0330 / AISI 1008) and is zinc-plated and chromated (Cr VI free), giving it additional protection against corrosion and external influences. What sets this AS-11 axial seal further apart is that the metal casing is extended in the axial direction at the outer diameter. This extension acts like a protective cap: it shields the sealing lip from damage caused by dirt, chips or contact during installation, while also helping the ring remain firmly and stably seated on the shaft.

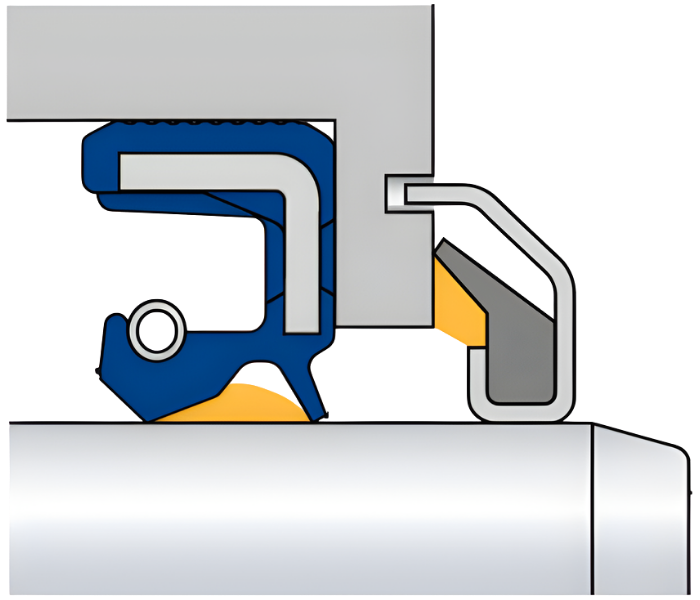

The axial seal AS-11 works axially, and this means that the elastomer lip seals against a flat counterface, such as a cover or flange. In many designs, a continuous groove is incorporated in that counterface, so the extended casing and the groove together create an additional labyrinth seal. This labyrinth intercepts part of the contamination before it even reaches the lip, reducing wear and the risk of leakage. In practice, the metal ring also behaves like a kind of pendulum disc: small misalignments or dynamic movements are “followed” more easily than with some tightly guided contact seals. During operation, the centrifugal action of the metal ring further helps to fling dirt and moisture outward, while friction generally decreases at higher circumferential speeds.

You will often find the AS-11 axial seal in wheel hubs, agricultural and construction machinery, pumps and drive systems, but also in broader machine building such as electric motors and even applications like washing machines where bearings and internal seals need protection against splash water and contamination. In exactly these environments you are dealing with mud, water, dust or swarf from the outside, while internally you want to protect grease or oil and keep bearings in good condition. The axial seal AS-11 suits these applications because it requires very little installation space, provides a good dynamic sealing function, and builds extra protection through the centrifugal effect and the labyrinth principle of the design. In addition, the counterface typically does not have to meet extremely strict requirements, which makes it practical in robust machinery and in housings that are not always “perfect” in real-world conditions.

The sealing lip is available in NBR and FKM. NBR is usually the logical all-round choice for standard oil and grease environments: it’s cost-effective, performs well with mineral lubricating oils and greases, and it is in many cases also suitable for common hydraulic oils. The downside is that NBR ages faster at higher temperatures and is less resistant to ozone, UV and some more aggressive media; hot water is also typically limited (in many applications to around 80 °C). You choose FKM when temperature and/or chemical exposure is more demanding, for example at higher operating temperatures, with synthetic oils, fuels or specific hydraulic fluids. FKM also performs clearly better in terms of ozone resistance, weathering, ageing and UV. On the other side, FKM is generally more expensive and can be less forgiving at low temperatures than NBR. It is important to note that the stated maximum values must not occur simultaneously in practice: if you are close to the temperature limit, you should choose more conservative speed and load conditions, and vice versa.

|

Material |

Temperature range |

Key properties |

|

NBR 70 |

-40 °C to +100 °C |

All-round for mineral oil and greases, strong price/performance, widely applicable; less suitable for high temperature and ozone/UV/ageing |

|

FKM 70 |

-30 °C to +180 °C |

Best choice for higher temperature and tougher chemistry (e.g., synthetic oils/fuels); very good against ozone/UV/weathering; generally, more expensive and less suitable at low temperatures than NBR |

Within the axial seal range, the AS-11 axial seal is often compared to the AS-10 axial seal. The AS-11 type is the more robust version with an axially extended metal casing, allowing you to achieve extra protection and a labyrinth effect if the counterface is designed accordingly. An AS-10 is simpler and may be perfectly sufficient when contamination levels are limited or when there is no space or possibility to incorporate the labyrinth groove. Compared with a radial shaft seal (such as the SC oil seal or the TC oil seal), the AS-11 has a different role: a radial seal is the primary seal to retain oil or grease, whereas the axial seal AS-11 is mainly intended to protect the radial seal and bearings from external influences. In many applications, they therefore work together: an AS-11 on the outside and a radial seal on the inside. Compared with a fully non-contact labyrinth seal, the AS-11 axial seal is generally more compact and easier, while a “true” labyrinth becomes particularly attractive at extremely high speeds and with minimal friction, but often requires more space and tighter machining accuracy.

Selection starts with the dimensions and the installation situation. Because the AS-11 axial seal is mounted on the shaft with an interference fit, you choose a version whose inner diameter matches your shaft diameter and the manufacturer’s recommended fits. Next, you look at the counterface: you need a flat surface for the lip to seal against, and if you want to get the most out of the axial seal AS-11 concept, you design a continuous groove in that counterface so the labyrinth seal is created. At the same time, the installation space determines the axial preload: the distance and position of the ring set how firmly the lip is pressed against the counterface. More preloads generally provide a “tighter” seal, but it also increases friction and wear; too little preload can reduce sealing performance. The total axial contact force is influenced not only by the mounting position, but also by the lip geometry and the elastic properties of the selected material.

You should choose the lip material based on the operating conditions: NBR for standard oil/grease and normal temperatures, and FKM for higher temperatures, synthetic oils, fuels and environments where ozone/UV/ageing play a role. Always check the max speed as well (often up to around 12 m/s, depending on conditions) and keep in mind that this type is intended for unpressurised applications (0 MPa). For installation, lightly grease the lip before start-up to reduce initial friction and support service life, and press the ring into position using a suitable installation tool and even force. Do not use a hammer, to avoid damage or misalignment. If axial access is limited, the installation tool must be able to “lock in” the required preload so the ring ends up in the correct position in one operation. Also store the AS-11 axial seal in a way that prevents the lip from being deformed or damaged, because this can directly affect sealing performance.

|

Brand / Manufacturer |

Equivalent type |

|

Anyseals |

AS-11 |

|

Simrit |

MSC 02 |

|

Trelleborg |

TBR |

|

Forsheda Stefa |

9RB |

|

Dichtomatik |

VRM02 |

|

Taiwan / China |

RE1 |

In summary, the Axial Seal AS-11 offers superior sealing performance and reliable protection in a wide range of applications. Its simple yet efficient design, small installation width, and excellent sealing capabilities make it an ideal choice for various industries. With the AS-11, you can trust in its ability to safeguard your equipment and machinery from contaminants, ensuring optimal performance and extended lifespan.

If you want more information about Axial seals AS-11, feel free to contact us.

Not in the classic sense. The AS-11 is primarily a protective seal against external influences and is often used ahead of a radial shaft seal or a bearing arrangement.

No. This type is intended for unpressurised conditions; the datasheet specifies 0 MPa.

Choose NBR for standard oil/grease and normal temperatures. Choose FKM for higher temperatures, synthetic oils/fuels and when you need extra resistance to ozone, UV and ageing.

That casing protects the elastomer, helps the ring stay firmly on the shaft, and enables an additional labyrinth effect in combination with a continuous groove in the counterface.

Often in wheel hubs, agricultural and construction machinery, pumps and drive systems, but also in general machine building such as electric motors and applications where protection against splash water and dirt is important.

Didn't find the right Axial Seal AS-11?

Complete the form below and we will help you!