| Product | Product Id | Type | Inside Diameter | Outer Diameter | Height | Material | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

57737 | Domsel Oil Seal | 20 mm | 47 mm | 7 mm | NBR - Nitrile | Black | 0 | € 29,26 | Details | Quote |

|

57740 | Domsel Oil Seal | 20 mm | 47 mm | 7 mm | FPM - VITON | Black | 0 | € 87,83 | Details | Quote |

|

57743 | Domsel Oil Seal | 20 mm | 52 mm | 9 mm | NBR - Nitrile | Black | 0 | € 21,78 | Details | Quote |

|

57746 | Domsel Oil Seal | 20 mm | 52 mm | 9 mm | FPM - VITON | Black | 0 | € 57,80 | Details | Quote |

|

57749 | Domsel Oil Seal | 20 mm | 52 mm | 9 mm | NBR - Nitrile | Black | 0 | € 32,66 | Details | Quote |

|

57752 | Domsel Oil Seal | 20 mm | 52 mm | 9 mm | FPM - VITON | Black | 0 | € 97,97 | Details | Quote |

|

57755 | Domsel Oil Seal | 22 mm | 30 mm | 7 mm | NBR - Nitrile | Black | 0 | € 17,35 | Details | Quote |

|

57757 | Domsel Oil Seal | 22 mm | 30 mm | 7 mm | FPM - VITON | Black | 0 | € 36,82 | Details | Quote |

|

57759 | Domsel Oil Seal | 22 mm | 30 mm | 7 mm | NBR - Nitrile | Black | 0 | € 20,82 | Details | Quote |

|

57761 | Domsel Oil Seal | 22 mm | 30 mm | 7 mm | FPM - VITON | Black | 0 | € 62,42 | Details | Quote |

|

57763 | Domsel Oil Seal | 22 mm | 32 mm | 7 mm | NBR - Nitrile | Black | 0 | € 19,76 | Details | Quote |

|

57766 | Domsel Oil Seal | 22 mm | 32 mm | 7 mm | FPM - VITON | Black | 0 | € 41,79 | Details | Quote |

|

57769 | Domsel Oil Seal | 22 mm | 32 mm | 7 mm | NBR - Nitrile | Black | 0 | € 23,67 | Details | Quote |

|

57772 | Domsel Oil Seal | 22 mm | 32 mm | 7 mm | FPM - VITON | Black | 0 | € 71,06 | Details | Quote |

|

57775 | Domsel Oil Seal | 22 mm | 35 mm | 7 mm | NBR - Nitrile | Black | 0 | € 19,76 | Details | Quote |

|

57778 | Domsel Oil Seal | 22 mm | 35 mm | 7 mm | FPM - VITON | Black | 0 | € 41,79 | Details | Quote |

|

57781 | Domsel Oil Seal | 22 mm | 35 mm | 7 mm | NBR - Nitrile | Black | 0 | € 23,67 | Details | Quote |

|

57784 | Domsel Oil Seal | 22 mm | 35 mm | 7 mm | FPM - VITON | Black | 0 | € 71,06 | Details | Quote |

|

57787 | Domsel Oil Seal | 22 mm | 40 mm | 7 mm | NBR - Nitrile | Black | 0 | € 21,35 | Details | Quote |

|

57790 | Domsel Oil Seal | 22 mm | 40 mm | 7 mm | FPM - VITON | Black | 0 | € 45,11 | Details | Quote |

|

57793 | Domsel Oil Seal | 22 mm | 40 mm | 7 mm | NBR - Nitrile | Black | 0 | € 25,60 | Details | Quote |

|

57796 | Domsel Oil Seal | 22 mm | 40 mm | 7 mm | FPM - VITON | Black | 0 | € 76,76 | Details | Quote |

|

57799 | Domsel Oil Seal | 24 mm | 35 mm | 7 mm | NBR - Nitrile | Black | 0 | € 19,76 | Details | Quote |

|

57802 | Domsel Oil Seal | 24 mm | 35 mm | 7 mm | FPM - VITON | Black | 0 | € 41,79 | Details | Quote |

|

57805 | Domsel Oil Seal | 24 mm | 35 mm | 7 mm | NBR - Nitrile | Black | 19 | € 23,67 | Details | |

|

57808 | Domsel Oil Seal | 24 mm | 35 mm | 7 mm | FPM - VITON | Black | 0 | € 71,06 | Details | Quote |

|

57811 | Domsel Oil Seal | 24 mm | 38 mm | 8 mm | NBR - Nitrile | Black | 0 | € 21,35 | Details | Quote |

|

57813 | Domsel Oil Seal | 24 mm | 38 mm | 8 mm | FPM - VITON | Black | 0 | € 45,11 | Details | Quote |

|

57815 | Domsel Oil Seal | 24 mm | 38 mm | 8 mm | NBR - Nitrile | Black | 0 | € 25,60 | Details | Quote |

|

57817 | Domsel Oil Seal | 24 mm | 38 mm | 8 mm | FPM - VITON | Black | 0 | € 76,76 | Details | Quote |

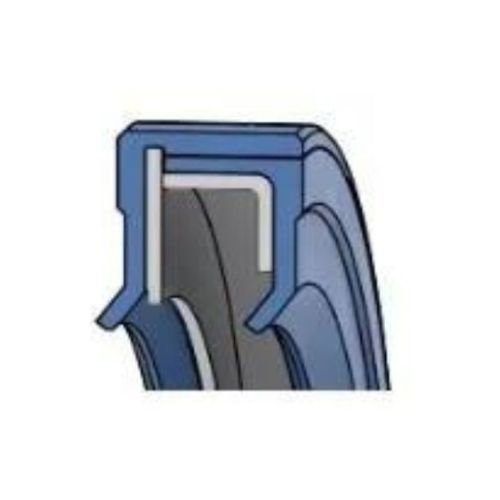

The Domsel AB consists of a flexible elastomer sealing lip (typically NBR or FKM), supported by a robust metal reinforcement ring. Unlike traditional oil seals, the AB does not rely on a spiral spring; instead, the lip itself provides sufficient radial pressure on the shaft to prevent leakage. This results in lower friction and reduced wear. The dual sealing lips are both directed inward, forming a grease chamber between them. This offers additional lubrication and significantly extends service life, especially in applications with little or no external lubrication. The metal ring prevents deformation during installation or high-temperature conditions and allows for press-fit installation according to DIN 3760.

The Domsel AB oil seal is used across a wide range of industries. In mechanical engineering, it ensures reliable sealing of bearings and gearboxes. In compressors and pumps, the seal performs well thanks to its pressure resistance of approximately 10 bar, and up to 15 bar in special versions. Due to its low friction coefficient and shaft-friendly lips, the AB seal is ideal for spindles, electric motors, and fans operating at high speeds. It is also widely used in the food processing industry, especially since it is available in various FDA-compliant versions. Its combination of chemical resistance, low friction, and long service life makes the Domsel AB a trusted choice for diverse industrial processes.

Domsel AB seals are available in a range of elastomer materials, each with its own advantages and limitations. NBR (nitrile rubber) is commonly used and cost-effective. It is resistant to oil, grease, and water, with a temperature range of approximately -20 °C to +100 °C. However, it is less suitable for chemically aggressive or high-temperature environments. FKM (Viton) provides excellent chemical resistance and withstands fuels, solvents, and temperatures up to +200 °C. It is ideal for heavy-duty industrial environments but is less elastic than NBR and more expensive. EPDM offers great resistance to hot water, steam, and cleaning agents, but is not resistant to oil or grease. It is often used in drinking water and steam applications. Silicone can withstand extreme temperatures from -60 °C to +200 °C but is mechanically weaker, making it suitable mainly for low-pressure, low-friction applications. PTFE offers exceptional chemical resistance and temperature range. It has virtually no friction, but requires a finely polished shaft and is more expensive than the other materials.

HNBR (Hydrogenated Nitrile Rubber) is an upgraded version of standard NBR with enhanced mechanical strength, ozone resistance, and a wider temperature range of approximately -30 °C to +150 °C. It performs well in applications involving dynamic movement, heat, and oil exposure. However, HNBR is more expensive than standard NBR and less chemically resistant than FKM. FFKM (Perfluoroelastomer) is the premium choice for highly aggressive chemical and high-temperature environments, offering resistance up to +325 °C depending on formulation. It combines the elasticity of rubber with the chemical resistance of PTFE. FFKM seals are ideal for semiconductor, pharmaceutical, and aerospace applications, though the cost is significantly higher.

The seal housing is typically made from galvanized steel or stainless steel (for corrosion-sensitive environments).

|

Material |

Temperature Range |

Key Strengths |

Limitations |

|

NBR (nitrile rubber) |

-20 °C to +100 °C |

Resistant to oil, grease, water; cost-effective |

Not suitable for high temperatures or harsh chemicals |

|

HNBR |

-30 °C to +150 °C |

Improved strength and ozone resistance; good oil performance |

Higher cost than NBR; limited chemical resistance |

|

FKM (Viton) |

-30 °C to +200 °C |

Excellent chemical and heat resistance |

Less elastic; more expensive |

|

FFKM |

-10 °C to +325 °C |

Exceptional chemical and thermal resistance |

Very high cost |

|

EPDM |

-40 °C to +150 °C |

Ideal for water, steam, cleaning agents |

Not oil- or grease-resistant |

|

Silicone |

-60 °C to +200 °C |

Flexible at extreme temperatures, inert |

Low mechanical strength; not pressure-resistant |

|

PTFE |

-60 °C to +260 °C |

Outstanding chemical resistance, low friction |

Expensive; requires polished shaft; brittle |

While the Domsel AB offers numerous advantages, there are situations where another Domsel type may be more appropriate. The Domsel A is the basic version with a single sealing lip facing the media side. It is intended for standard applications with sufficient lubrication and low to moderate pressure. It has a simpler design and is therefore more economical, but offers less protection under poor lubrication or changing pressure directions. The Domsel A-SF is a special variant designed for high-pressure applications up to 15 bar with limited installation space. It features a reinforced construction and can be installed from either side, offering more flexibility. Compared to the A, the AB provides better protection in poor lubrication conditions and when sealing air or gas. Compared to the A-SF, the AB is slightly wider and less pressure-resistant but suitable for most standard applications. The choice between these types depends on pressure, space constraints, media type, and lubrication conditions.

When selecting the appropriate Domsel AB seal, several factors should be considered. The shaft diameter (d) and housing diameter (D) must match DIN 3760 standard sizes. The seal is installed with a press-fit into the housing. Use a fit such as H8/f8 to prevent leakage or loosening. The installation width (B) also matters; ensure you have enough space for the seal's width. The standard AB typically ranges from 7 to 15 mm in width. Operating conditions are crucial, select the material based on temperature, pressure, media (oil, gas, water, etc.), and chemical exposure. FKM or PTFE is recommended for high-temperature or aggressive chemical environments. For standard industrial use, NBR is usually sufficient. For high speeds or poor lubrication, double-lip designs like the AB perform better. Also, consider the maximum circumferential speed, which is approximately 32 m/s.

In summary, the Domsel Seal AB is a high-performance sealing solution designed to meet the rigorous demands of the machine building industry. Its exceptional frictional characteristics, impressive pressure and temperature resistance, and high chemical resistance make it a top choice for various applications. Whether it's sealing compressed air, gases, or tackling challenging low-lubricating grease sealing points, the Domsel Seal AB delivers reliable and efficient sealing performance. Trust in the Domsel Seal AB for your sealing needs and experience the benefits of a superior sealing solution in your rotating machinery.

The Domsel AB does not use a spiral spring and features dual lips, resulting in lower friction, longer service life, and higher pressure resistance.

Yes, the standard version handles up to 10 bar, and special types like the AB-SF can handle up to 15 bar.

Use NBR for oil and general-purpose use, FKM for high temperature and chemical exposure, EPDM for water or steam, and PTFE for highly aggressive chemical environments.

Yes, many versions are FDA-compliant and available with stainless steel housings.

No, the sealing lip applies minimal pressure and does not create grooves in the shaft, even on unhardened surfaces.

Didn't find the right Domsel Seal AB?

Complete the form below and we will help you!