| Product | Product Id | Type | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Garlock Number | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

32178 | Garlock PS Seal | 80 | 100 | 10 | GYLON | SS 316 | BR/WHITE | MEC14-10034 | 0 |

Request

|

Details | Quote |

|

32163 | Garlock PS Seal | 40 | 55 | 10 | GYLON MS | SS 316 | Black | MEC04-14594 | 0 |

Request

|

Details | Quote |

|

32138 | Garlock PS Seal | 25 | 35 | 7 | GYLON | SS 316 | Blue | MEC04-11699 | 0 |

Request

|

Details | Quote |

|

32137 | Garlock PS Seal | 25 | 35 | 8 | GYLON | SS 316 | Blue | MEC04-12703 | 0 |

Request

|

Details | Quote |

|

32135 | Garlock PS Seal | 50 | 65 | 8 | GYLON | SS 316 | Blue | MEC04-14298 | 0 | € 205,42 | Details | Quote |

|

32134 | Garlock PS Seal | 40 | 55 | 8 | GYLON | SS 316 | Blue | MEC04-13405 | 0 | € 190,61 | Details | Quote |

|

30085 | Garlock PS Seal | 30 | 47 | 10 | GYLON | SS 316 | White/Blue | MEC05-10897 | 0 |

Request

|

Details | Quote |

|

30064 | Garlock PS Seal | 185 | 215 | 15 | GYLON F | SS 316 | Off White/Blue | MEC05-10821 | 0 |

Request

|

Details | Quote |

|

28150 | Garlock PS Seal | 70 | 90 | 10 | GYLON | SS 316 | White/Blue | MEC04-10322 | 0 | € 270,51 | Details | Quote |

|

26600 | Garlock PS Seal | 30 | 47 | 7 | GYLON | SS 316 | Black | MEC04-10524 | 0 |

Request

|

Details | Quote |

|

26540 | Garlock PS Seal | 50 | 72 | 8 | GYLON | SS 316 | White/Blue | MEC04-11316 | 0 | € 214,89 | Details | Quote |

|

27407 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | Black | MEC04-12585 | 0 |

Request

|

Details | Quote |

|

27965 | Garlock PS Seal | 60 | 75 | 8 | GYLON | SS 316 | Black | MEC04-12264 | 0 |

Request

|

Details | Quote |

|

28346 | Garlock PS Seal | 90 | 110 | 10 | GYLON | SS 316 | White/Blue | MEC04-10611 | 3 | € 310,28 | Details | |

|

28349 | Garlock PS Seal | 90 | 110 | 10 | GYLON | SS 316 | Black | MEC04-11094 | 0 | € 286,36 | Details | Quote |

|

83003 | Garlock PS Seal | 25 | 42 | 8 | GYLON | SS 316 | Black | MEC04-10836 | 0 |

Request

|

Details | Quote |

|

83004 | Garlock PS Seal | 25 | 42 | 8 | GYLON MS | SS 316 | Black | MEC04-14825 | 0 |

Request

|

Details | Quote |

|

83005 | Garlock PS Seal | 35 | 47 | 8 | GYLON | SS 316 | Black | MEC04-14552 | 0 |

Request

|

Details | Quote |

|

83019 | Garlock PS Seal | 16 | 28 | 8 | GYLON | SS 316 | Blue | MEC04-13721 | 0 |

Request

|

Details | Quote |

|

83023 | Garlock PS Seal | 45 | 72 | 8 | GYLON | SS 316 | White | MEC04-14886 | 0 | € 216,10 | Details | Quote |

|

83086 | Garlock PS Seal | 30 | 47 | 10 | GYLON F | SS 316 | Off White/Blue | MEC04-13966 | 0 | € 147,91 | Details | Quote |

|

83120 | Garlock PS Seal | 35 | 50 | 10 | GYLON | SS 316 | Blue | MEC04-13972 | 0 | € 155,30 | Details | Quote |

|

83129 | Garlock PS Seal | 35 | 52 | 9 | GYLON | SS 316 | White/Blue | MEC04-10914 | 0 | € 171,49 | Details | Quote |

|

83131 | Garlock PS Seal | 35 | 52 | 8 | GYLON | SS 316 | Black | MEC04-13319 | 0 | € 168,22 | Details | Quote |

|

83228 | Garlock PS Seal | 50 | 65 | 10 | GYLON | SS 316 | White/Blue | MEC04-12577 | 0 | € 237,45 | Details | Quote |

|

83243 | Garlock PS Seal | 50 | 65 | 8 | GYLON | SS 316 | Black | MEC04-13833 | 0 | € 192,15 | Details | Quote |

|

83245 | Garlock PS Seal | 45 | 65 | 10 | GYLON | SS 316 | Blue | MEC04-13973 | 0 | € 174,24 | Details | Quote |

|

83246 | Garlock PS Seal | 50 | 65 | 10 | GYLON | SS 316 | Blue | MEC04-13974 | 0 | € 174,24 | Details | Quote |

|

83261 | Garlock PS Seal | 50 | 68 | 10 | GYLON F | SS 316 | Off White | MEC04-13861 | 0 | € 203,35 | Details | Quote |

|

83278 | Garlock PS Seal | 50 | 70 | 8 | GYLON | SS 316 | White/Blue | MEC04-14046 | 0 | € 289,27 | Details | Quote |

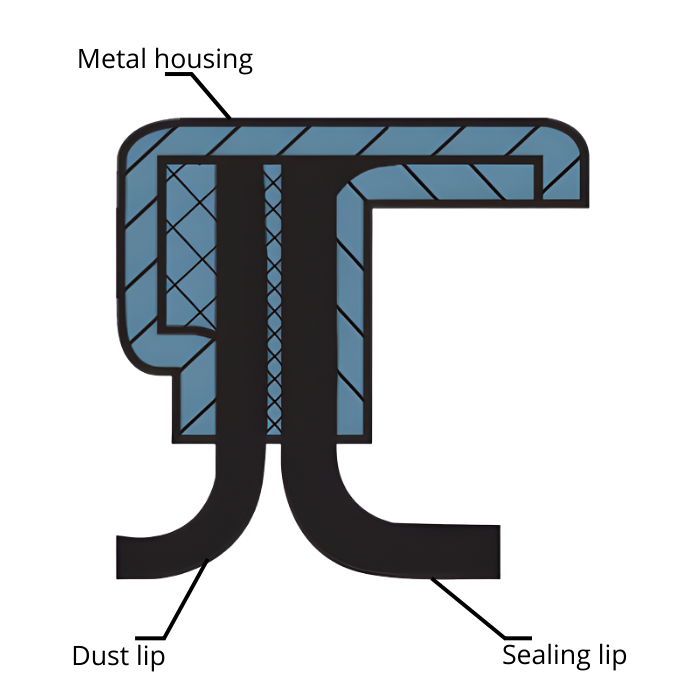

In its basic form, the PS-SEAL consists of a stainless-steel housing (1.4571 / 316SS) containing a GYLON® (modified PTFE) sealing lip and a static sealing element made of FKM. The metal case provides a rigid, stable fit in the housing bore, while the PTFE lip runs directly on the shaft to create a low-friction dynamic seal. Garlock does not use a traditional metal garter spring as found in many oil seals; instead, the lip materials and geometry generate the required sealing preload with low drag and consistent contact. The Dustlip is a non-standard lip configuration (“with dust lip”), meaning that in addition to the main lip you get an extra shielding lip that helps keep dust, dirt, and splash water away from the primary sealing edge.

You typically choose a PS-SEAL (Dustlip) when you are dealing with external contamination such as dirt, dust, mud, or splash water on the outside, combined with heavier conditions such as higher pressure or vacuum, high shaft speeds, chemically aggressive or abrasive media, and a wide temperature range (guideline -90 °C to +260 °C). In such situations, the Dustlip helps keep contamination away from the main lip, which in practice keeps the seal stable for longer. Garlock also positions the PS-SEAL as an alternative to braided packings and in some cases even to mechanical seals (depending on the duty).

Garlock supplies multiple GYLON® (modified PTFE) lip materials to match the PS-SEAL (Dustlip) to the medium, hygiene requirements, and (dry) running conditions. GYLON® Black (graphite) is the standard choice for general industrial use, especially when there is sufficient lubrication and you want maximum all-round performance without food requirements. For food/pharma, you typically choose GYLON® White (food compliance, suitable for process media) or GYLON® Blue, which is especially known for higher flexibility and strong dry-running properties. For abrasive media, options include Brown-White (less sensitive to abrasion within a food context) and industrial compounds such as MS (focused on wear resistance in abrasive duty) and KF (a good balance for partially abrasive conditions, with decent dry-running performance). F Econol is often chosen when you place strong emphasis on dry running and/or vacuum applications.

|

Material (GYLON® lip) |

Temp range (guideline) |

Key properties |

|

Black (graphite filled PTFE) |

approx. -90 °C to +260 °C |

Industrial all-round, low friction, strong in lubricated applications |

|

White (barium sulfate filled PTFE) |

approx. -90 °C to +260 °C |

Food/pharma oriented, good chemical resistance, suitable for process media |

|

Blue (glass microspheres filled PTFE) |

approx. -90 °C to +260 °C |

Very flexible (high recovery), strong dry-running properties, more “forgiving” under variation |

|

Brown-White (dual compound) |

approx. -90 °C to +260 °C |

Extra wear-resistant in abrasive media (also in food context), improved heat/wear management |

|

F (Econol filled PTFE) |

approx. -90 °C to +260 °C |

Excellent for (partial) dry running and vacuum applications |

|

MS (MoS₂ filled PTFE) |

approx. -90 °C to +260 °C |

Wear-resistant in abrasive media, robust in heavier “dirty” duty |

|

KF (carbon fiber filled PTFE) |

approx. -90 °C to +260 °C |

Good balance: wear-resistant (partially abrasive) + decent dry running |

Within the PS-SEAL family, the differences mainly come down to lip configuration and the problem you want to solve. The Standard PS-SEAL is the “single-lip” version: compact and efficient for sealing in one direction when the environment is relatively clean. Dustlip adds an extra lip on the outside that is mainly intended to keep dirt, dust, and splash water away from the main lip; you choose this when the outside of the machine is “dirty” and you want to increase service life. The PS-SEAL Reverse is still a single lip, but installed in the opposite direction, and becomes especially relevant when you want the product side to be as “clean” and smooth as possible (for example, for hygienic design or to limit dead spaces). The Tandem PS-SEAL uses two lips in the same direction: this is intended to increase sealing security or distribute the load (for example, if you want just a bit more assurance against leakage without a true two-sided separation). The PS-SEAL Back-to-Back has two lips in opposite directions and is therefore the logical choice if you want to seal in both directions or if you want to separate the internal medium and the external environment with one unit (a more “double-sided” function than Dustlip).

Start with the size format d1 × d2 × B (shaft diameter, bore diameter, width/height) and work from there toward fit and surface finish. Follow the recommended tolerances for shaft and bore, and pay extra attention to shaft/counterface quality: with PTFE lips, roughness, runout, and machining marks make the difference between “good” and “just not quite.” Then select the lip material based on your operating conditions: for generally lubricated industrial service this is often GYLON® Black; for food/pharma applications you typically choose GYLON® White, GYLON® Blue, or F Econol; for (partial) dry running or vacuum duty GYLON® Blue and F Econol are common directions; and for abrasive duty you look at Brown-White, MS, or KF. Finally, verify that your pressure/speed combination fits within the intended duty, especially in heavier operating conditions.

In summary, Garlock PS-Seal Dustlip is a reliable and versatile sealing solution for rotating shafts. With its exceptional resistance to high pressure, extreme vacuum, chemical aggression, and wide temperature range, this seal ensures reliable performance in demanding applications. The use of Gylon as the sealing lip material further enhances the seal's capabilities, delivering effective sealing and increased uptime. Trust in Garlock's expertise and choose PS-Seal Dustlip for your shaft sealing needs.

Find all our other PS-Seals or our full range of Garlock Seals here!!

The Dustlip is an extra lip on the atmospheric side that helps keep dust/dirt/splash water away from the primary sealing lip.

Yes, depending on the selected lip material. Garlock states the PS-SEAL can be used for food/pharma (FDA) and also mentions EN 1935/2004.

Garlock states: PS-SEAL Standard max. 145 psi (~10 bar) and Non-Standard max. 362 psi (~25 bar) (depending on the version). Dustlip falls under Non-Standard.

Yes, the PS-SEAL is intended for high pressure as well as (extreme) vacuum; moreover, there is lip material (e.g., F Econol) that is explicitly described as suitable for vacuum applications.

Guidelines: Ra 0.1–0.4 μm, no spiral machining marks, and approximately 60 HRC hardness.

Didn't find the right PS-Seal (Dustlip)?

Complete the form below and we will help you!