| Product | Product Id | Type | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Garlock Number | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

26533 | Garlock PS Seal | 40 | 62 | 8 | GYLON | SS 316 | White/Blue | MEC04-10549 | 0 | € 158,02 | Details | Quote |

|

27411 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | Blue | MEC04-12872 | 0 | € 160,82 | Details | Quote |

|

27409 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | White/Blue | MEC04-12627 | 0 |

Request

|

Details | Quote |

|

27402 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | Blue | MEC04-12162 | 4 | € 132,03 | Details | |

|

27401 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | White/Blue | MEC04-12027 | 0 | € 158,02 | Details | Quote |

|

27397 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | White/Blue | MEC04-10889 | 0 |

Request

|

Details | Quote |

|

27395 | Garlock PS Seal | 40 | 55 | 10 | GYLON | SS 316 | White/Blue | MEC04-10548 | 0 | € 132,03 | Details | Quote |

|

27387 | Garlock PS Seal | 40 | 55 | 8 | GYLON F | SS 316 | Off White/Blue | MEC04-12686 | 0 | € 144,28 | Details | Quote |

|

27370 | Garlock PS Seal | 40 | 55 | 7 | GYLON | SS 316 | White | MEC04-12126 | 0 | € 144,28 | Details | Quote |

|

27365 | Garlock PS Seal | 40 | 55 | 6 | GYLON | SS 316 | White/Blue | MEC04-11984 | 0 | € 144,28 | Details | Quote |

|

27364 | Garlock PS Seal | 40 | 52 | 9 | GYLON | SS 316 | White/Blue | MEC04-12717 | 0 |

Request

|

Details | Quote |

|

27358 | Garlock PS Seal | 40 | 52 | 7 | GYLON | SS 316 | White/Blue | MEC04-11666 | 0 | € 157,62 | Details | Quote |

|

27353 | Garlock PS Seal | 39 | 60 | 10 | GYLON | SS 316 | White/Blue | MEC04-12870 | 0 |

Request

|

Details | Quote |

|

27334 | Garlock PS Seal | 37.5 | 50 | 10 | GYLON | SS 316 | White/Blue | MEC04-11934 | 0 |

Request

|

Details | Quote |

|

27306 | Garlock PS Seal | 35 | 52 | 9 | GYLON | SS 316 | White/Blue | MEC04-12381 | 0 | € 186,65 | Details | Quote |

|

27289 | Garlock PS Seal | 35 | 50 | 10 | GYLON F | SS 316 | Off White/Blue | MEC04-12313 | 0 | € 126,72 | Details | Quote |

|

27279 | Garlock PS Seal | 35 | 50 | 10 | GYLON | SS 316 | Blue | MEC04-11711 | 0 | € 126,72 | Details | Quote |

|

27276 | Garlock PS Seal | 35 | 50 | 10 | GYLON | SS 316 | White | MEC04-10755 | 0 | € 126,72 | Details | Quote |

|

27275 | Garlock PS Seal | 35 | 50 | 10 | GYLON | SS 316 | White/Blue | MEC04-10223 | 0 | € 126,72 | Details | Quote |

|

27267 | Garlock PS Seal | 35 | 50 | 8 | GYLON | SS 316 | Blue/White | MEC04-11654 | 0 |

Request

|

Details | Quote |

|

27263 | Garlock PS Seal | 35 | 50 | 8 | GYLON | SS 316 | White | MEC04-11118 | 0 | € 158,42 | Details | Quote |

|

27260 | Garlock PS Seal | 35 | 50 | 7 | GYLON | SS 316 | Black | MEC04-11945 | 0 |

Request

|

Details | Quote |

|

27254 | Garlock PS Seal | 35 | 47 | 10 | GYLON | SS 316 | Blue | MEC04-12193 | 0 | € 154,66 | Details | Quote |

|

27253 | Garlock PS Seal | 35 | 47 | 10 | GYLON | SS 316 | White/Blue | MEC04-11968 | 0 | € 154,66 | Details | Quote |

|

27244 | Garlock PS Seal | 35 | 47 | 8 | GYLON | SS 316 | Black | MEC04-12481 | 0 |

Request

|

Details | Quote |

|

27234 | Garlock PS Seal | 35 | 47 | 8 | GYLON | SS 316 | Black | MEC04-10539 | 0 |

Request

|

Details | Quote |

|

27233 | Garlock PS Seal | 35 | 47 | 8 | GYLON | SS 316 | White/Blue | MEC04-10221 | 0 | € 113,94 | Details | Quote |

|

27230 | Garlock PS Seal | 35 | 47 | 7 | GYLON | SS 316 | Blue/White | MEC04-12168 | 0 |

Request

|

Details | Quote |

|

27228 | Garlock PS Seal | 35 | 47 | 7 | GYLON | SS 316 | White/Blue | MEC04-11259 | 0 | € 142,46 | Details | Quote |

|

27219 | Garlock PS Seal | 33 | 50 | 7 | GYLON | SS 316 | White/Blue | MEC04-11535 | 0 | € 158,42 | Details | Quote |

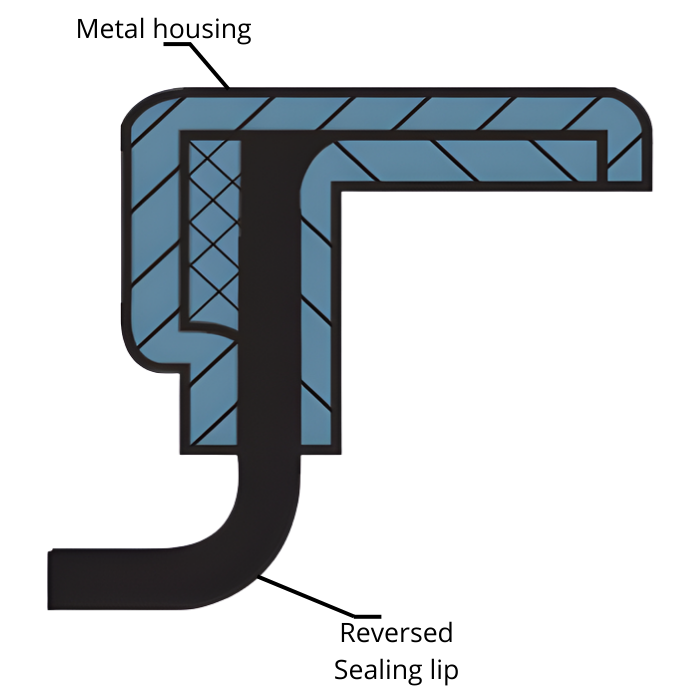

In terms of design, the PS-SEAL Reverse is a compact unit with a stainless-steel housing (standard 1.4571 / 316SS) and a dynamic sealing lip made of GYLON® (modified PTFE) or other modified PTFE materials; in addition, there is a static sealing element (often FKM in the standard PS-SEAL) that seals the bore. The concept is that the lip materials and lip geometry create the seal (no “classic” elastomer lip doing all the work), which allows the seal to be low-friction and wear-resistant and to remain suitable in conditions where elastomers struggle. The PS-SEAL product line is also available as Standard (fixed base configuration) and as Non-Standard (lip configurations such as reverse, tandem, back-to-back, dust lip) where lip material and layout can vary; in principle, Non-Standard sizes are available in the same size series as Standard, with limited customization range.

You typically see the Reverse version in mixers/agitators, pumps, process equipment and hygienic machines where (1) the operating conditions are demanding and (2) cleanability matters: Garlock explicitly mentions food & pharma as sectors where the reverse lip is widely used and appreciated. The logic is twofold: you get the familiar PS-SEAL advantages (PTFE lip, chemical resistance, wide temperature range, suitable for high circumferential speed and also in extreme vacuum) and, thanks to the reverse lip configuration, often a more “hygienic” profile with less dead space around the product area, so CIP/SIP and general cleaning carry less risk of product build-up.

For the PS-SEAL Reverse, the lip material is your most important choice, because it determines the combination of dry-running behavior, chemistry, wear and (food) compliance: GYLON® Black (PTFE/graphite) is excellent for lubricated applications but not intended for dry running and not for food/pharma; GYLON® White (PTFE with barium sulfate) is popular in food & pharma with relevant certifications and good gas tightness, but in dry running you need to limit circumferential speed because frictional heat can rise quickly; GYLON® Blue is Garlock’s “top” choice for food & pharma, good with greater shaft deflection and strong in dry running with good gas tightness, but in truly abrasive media the microsphere material can be more sensitive; GYLON® Brown-White was developed specifically for abrasive applications in food (wear-resistant “brown” side + heat-dissipating “white” side) to increase service life; Material F (beige, PTFE Ekonol-based) is designed for dry running (also at higher speed with low frictional heat) and is valued in vacuum and CIP/SIP, but requires good concentric shaft running to fully realize the benefits; Material MS (grey) is intended for abrasive powders/dust, can handle dry running well, offers high pressure resistance with low wear, and is also combined in tandem to boost performance with low-viscosity media/gases.

|

Material |

Temp range (typical PS-SEAL lip material range) |

Key properties (strengths / weaknesses) |

|

GYLON® Black (PTFE/graphite) |

approx. -90°C to +260°C |

Excellent for lubricated applications; not intended for dry running; not for food/pharma. |

|

GYLON® White (PTFE + barium sulfate) |

approx. -90°C to +260°C |

Popular in food & pharma; relevant certifications; good gas tightness; under dry running limit circumferential speed because frictional heat can rise quickly. |

|

GYLON® Blue (microsphere-based) |

approx. -90°C to +260°C |

Garlock’s “top” choice for food & pharma; good with greater shaft deflection; strong in dry running; good gas tightness; may be more sensitive in truly abrasive media. |

|

GYLON® Brown-White |

approx. -90°C to +260°C |

Developed for abrasive applications in food; wear-resistant “brown” side + heat-dissipating “white” side to increase service life. |

|

Material F (beige, PTFE Ekonol-based) |

approx. -90°C to +260°C |

Designed for dry running (also at higher speed with low frictional heat); valued in vacuum and CIP/SIP; needs good concentric shaft running to fully realize benefits. |

|

Material MS (grey) |

approx. -90°C to +260°C |

Intended for abrasive powders/dust; handles dry running well; high pressure resistance with low wear; often used in tandem to boost performance with low-viscosity media/gases. |

Within PS-SEAL you broadly have Standard and Non-Standard: the PS-SEAL Standard is the fixed base (stainless-steel 1.4571 housing + GYLON Black lip + static FKM) and is positioned in that brochure as max. 10 bar / max. 205 °C / no FDA; the PS-SEAL Non-Standard is the platform for variants such as Reverse lip PS-SEAL (lip towards the media), Tandem PS-SEAL (two lips in the same direction for extra security), Back-to-back PS-SEAL (two lips opposed to separate two sides) and the dustlip PS-SEAL (extra lip against contamination). In practice, you don’t choose Reverse because it is “always better”, but because the lip direction and the often improved cleanability/contamination control make the difference; if you want to separate two media you would choose back-to-back, and if you want redundancy with difficult media or higher pressure you would choose tandem.

Always start with the installation dimensions d1 × d2 × B (shaft diameter × bore × width) and then select the lip material based on lubrication (wet/dry), media (chemistry/abrasion), temperature, pressure and hygiene requirements; Garlock also emphasizes the importance of the p×v value at higher pressure, and advises axial fixation of the PS-SEAL in high-pressure applications and attention to frictional heat (seal temperature can be higher than process temperature). For fits/tolerances, their dimensional specification explicitly shows ISO-like tolerances, such as d2 H8 (bore) and d1 h11 (shaft) and a B tolerance (e.g., B +0.3 mm in the shown example), which aligns well with the ISO 286 fits system; in your selection text you can keep this practical: “work with the H8/h11 guideline values specified by Garlock and check the size series for your d1/d2/B.” Finally: don’t underestimate the counterface/shaft surface, Garlock mentions, among other things, that the running surface must not have a spiral/helical machining mark (can cause pumping/leakage) and that at higher p×v loading a suitable coating (such as chromium oxide) can help; for installation: do not install over sharp edges, and a mounting paste makes installation safer.

In summary, Garlock PS-Seal Reverse is a reliable and versatile sealing solution for rotating shafts. With its exceptional resistance to high pressure, extreme vacuum, chemical aggression, and wide temperature range, this seal ensures reliable performance in demanding applications. The use of Gylon as the sealing lip material further enhances the seal's capabilities, delivering effective sealing and increased uptime. Trust in Garlock's expertise and choose PS-Seal Reverse for your shaft sealing needs.

Find all our other PS-Seals or our full range of Garlock Seals here!!

It means the sealing lip points outward, towards the media (“single lip points out of the housing towards the media”).

Because the reverse lip configuration can reduce dead space by almost 80%, which makes cleaning easier and reduces contamination risk; in addition, there are lip materials with FDA/EC 1935 options.

Sometimes: Garlock positions PS-SEAL as cost-effective and practical and states it can be an alternative to mechanical seals and braided packings, but it depends on pressure, p×v, media and zero-leakage requirements.

The brochures mention roughly -90 °C to +260 °C for PS-SEAL lip materials, with the note that friction can generate additional heat; in terms of pressure, it is stated among other things: Standard max. 10 bar and Non-Standard max. 25 bar (depending on version); always check p×v and the application.

Garlock mentions, among other things, GYLON Blue (strong in dry running), Material F (Ekonol-based) (specifically for dry running, also at higher speed) and Material MS (dry running in abrasive powder/dust environments).

Didn't find the right PS-Seal (Reverse)?

Complete the form below and we will help you!