| Product | Product Id | Type | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Garlock Number | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

27915 | Garlock PS Seal | 55 | 72 | 10 | GYLON F | SS 316 | Off White | MEC04-12556 | 0 |

Request

|

Details | Quote |

|

32174 | Garlock PS Seal | 90 | 115 | 12 | GYLON | SS-316 | Black | MEC05-11054 | 0 |

Request

|

Details | Quote |

|

32165 | Garlock PS Seal | 35 | 50 | 10 | GYLON | SS 316 | BR/WHITE | MEC04-13957 | 0 |

Request

|

Details | Quote |

|

32161 | Garlock PS Seal | 16 | 35 | 7 | GYLON | SS 316 | Blue/White | MEC04-14231 | 7 | € 119,44 | Details | |

|

32160 | Garlock PS Seal | 55 | 85 | 10 | GYLON | SS 316 | White | MEC04-10292 | 19 | € 199,00 | Details | |

|

32156 | Garlock PS Seal | 85 | 100 | 10 | GYLON F | SS 316 | Off White/Blue | MEC04-13015 | 0 |

Request

|

Details | Quote |

|

32152 | Garlock PS Seal | 100 | 130 | 10 | GYLON | SS 316 | BR/WHITE | MEC14-10113 | 0 |

Request

|

Details | Quote |

|

32148 | Garlock PS Seal | 10 | 25 | 7 | GYLON | SS 316 | Black | MEC05-10030 | 0 |

Request

|

Details | Quote |

|

32141 | Garlock PS Seal | 65 | 85 | 12 | GYLON | SS 316 | Black | MEC05-10682 | 0 |

Request

|

Details | Quote |

|

32139 | Garlock PS Seal | 110 | 130 | 10 | GYLON | SS 316 | Black | MEC04-13031 | 0 |

Request

|

Details | Quote |

|

32129 | Garlock PS Seal | 25 | 52 | 10 | GYLON F | SS 316 | Off White/Blue | MEC04-14269 | 0 | € 296,86 | Details | Quote |

|

32128 | Garlock PS Seal | 40 | 60 | 7 | GYLON | SS 316 | BR/WHITE | MEC14-10131 | 5 |

Request

|

Details | Quote |

|

30406 | Garlock PS Seal | 45 | 62 | 10 | GYLON | SS-316 | Blue | 0 |

Request

|

Details | Quote | |

|

30399 | Garlock PS Seal | 170 | 200 | 15 | GYLON MS | SS 316 | Black/Blue | MEC05-10642 | 0 |

Request

|

Details | Quote |

|

30398 | Garlock PS Seal | 170 | 200 | 15 | GYLON | SS 316 | Black/Blue | MEC05-10641 | 0 |

Request

|

Details | Quote |

|

30395 | Garlock PS Seal | 35 | 48 | 8 | GYLON | SS 316 | Black/Blue | MEC05-10816 | 0 |

Request

|

Details | Quote |

|

30394 | Garlock PS Seal | 25 | 38 | 8 | GYLON | SS 316 | Black/Blue | MEC05-10409 | 0 |

Request

|

Details | Quote |

|

30393 | Garlock PS Seal | 25 | 38 | 7 | GYLON | SS 316 | Black/Blue | MEC05-10767 | 0 |

Request

|

Details | Quote |

|

30391 | Garlock PS Seal | 12 | 32 | 7 | GYLON | SS 316 | Black/Blue | MEC05-10658 | 0 |

Request

|

Details | Quote |

|

30389 | Garlock PS Seal | 290 | 320 | 15 | GYLON | SS 316 | Black | MEC05-10848 | 0 |

Request

|

Details | Quote |

|

30386 | Garlock PS Seal | 220 | 245 | 12 | GYLON | SS 316 | Black | MEC05-10812 | 0 |

Request

|

Details | Quote |

|

30385 | Garlock PS Seal | 214.9 | 248 | 12 | GYLON KF | SS 316 | Black | MEC05-10535 | 0 |

Request

|

Details | Quote |

|

30384 | Garlock PS Seal | 210 | 240 | 15 | GYLON | SS 316 | Black | MEC05-10337 | 0 |

Request

|

Details | Quote |

|

30383 | Garlock PS Seal | 208 | 247.2 | 14.5 | GYLON | SS 316 | Black | MEC05-10624 | 0 |

Request

|

Details | Quote |

|

30382 | Garlock PS Seal | 200 | 230 | 15 | GYLON | SS 316 | Black | MEC05-10702 | 0 |

Request

|

Details | Quote |

|

30381 | Garlock PS Seal | 200 | 230 | 15 | GYLON | SS 316 | Black | MEC05-10343 | 0 |

Request

|

Details | Quote |

|

30380 | Garlock PS Seal | 200 | 230 | 12 | GYLON | SS 316 | Black | MEC05-10829 | 0 |

Request

|

Details | Quote |

|

30378 | Garlock PS Seal | 190 | 220 | 15 | GYLON | SS 316 | Black | MEC05-10837 | 0 |

Request

|

Details | Quote |

|

30377 | Garlock PS Seal | 190 | 220 | 15 | GYLON | SS 316 | Black | MEC05-10792 | 0 |

Request

|

Details | Quote |

|

30376 | Garlock PS Seal | 190 | 220 | 15 | GYLON | SS 316 | Black | MEC05-10347 | 0 |

Request

|

Details | Quote |

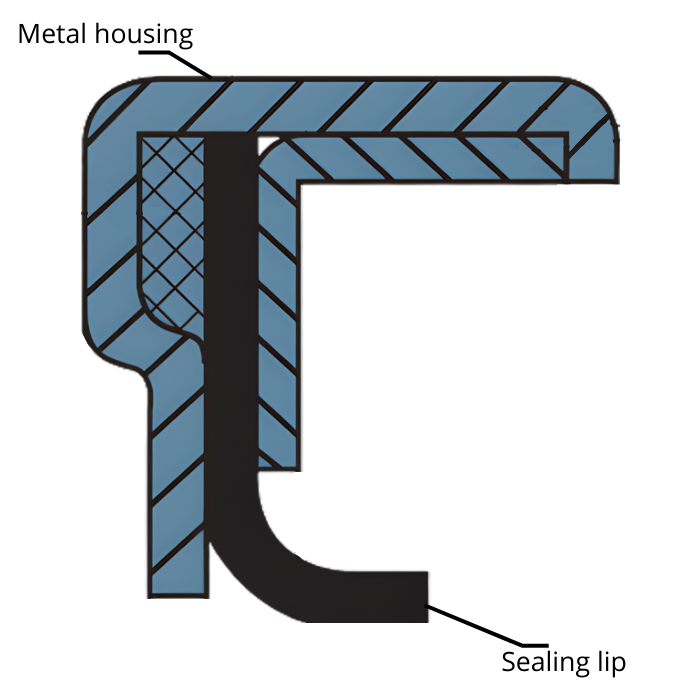

The standard configuration consists of a stainless-steel housing (1.4571 / 316SS) with a modified PTFE (GYLON®) sealing lip and a static sealing element (typically FKM in the base design). The sealing effect does not come from a classic garter spring like in many oil seals, but from the lip geometry and the properties of the PTFE/GYLON® material. Garlock manufactures these lip materials using its own, specific process developed to make PTFE suitable for dynamic shaft sealing, with a focus on dimensional stability, wear resistance, and consistent sealing.

For the counterface (shaft or sleeve), the surface finish remains decisive: a proper roughness, no spiral machining marks, and sufficient surface hardness help prevent leakage and accelerated wear. Especially at higher speeds or when lubrication is not ideal, counterface quality often makes the difference between “stable sealing” and “running too hot.”

The PS-SEAL Standard is selected in applications where a standard oil seal is heavily loaded due to p×v (pressure × speed), chemistry, temperature, or contamination. In the process industry and chemical applications, the broad resistance of PTFE/GYLON® helps against aggressive media, while the low friction is particularly attractive in equipment with higher shaft speeds. Depending on the version and boundary conditions, a PS-SEAL can also be used as a practical alternative to a mechanical seal, especially when you want to avoid the complexity and cost of a mechanical seal and the operating conditions remain within the PS-SEAL’s range. Thanks to the combination of wear resistance and low friction, friction losses decrease, heat generation is reduced, and in many cases you can expect less maintenance and longer service intervals.

The PS-SEAL Standard is the “base design,” but within the same family there are different lip materials you select based on hygiene requirements, dry running/vacuum behavior, speed, and abrasion. In practice: the more critical the application (e.g., food/pharma, vacuum, less lubrication, or more abrasion), the more important it is to match the lip material precisely to the duty. You can use the table below as a quick selection guide.

|

Material (lip) |

Temp. range (guideline) |

Key properties |

|

GYLON® Black (PTFE/graphite) |

–90 °C to +260 °C |

Strong in lubricated applications; stable at higher speed and pressure. Less suitable when significant dry running is expected and not intended as a food-grade base. |

|

GYLON® White (PTFE + barium sulfate) |

–90 °C to +260 °C |

Often chosen for food & pharma versions; clean / “non-shedding” material. Suitable when compliance and hygiene matter more than maximum robustness in dirty/abrasive conditions. |

|

GYLON® Blue (PTFE + microspheres) |

–90 °C to +260 °C |

Strong when lubrication is less ideal or (partial) dry running is expected; good “recovery” and more forgiving with minor deviations. Popular choice in hygienic environments. |

|

GYLON® Brown-White (dual PTFE) |

–90 °C to +260 °C |

Focused on abrasion combined with hygiene requirements: one side targets wear resistance, the other targets thermal management. Interesting for abrasive products or cleaning cycles that load the sealing point more heavily. |

|

Material F Beige (PTFE Ekonol) |

–90 °C to +260 °C |

Designed for dry running / reduced lubrication and applications where gas-tight behavior and stable sealing are important (e.g., certain vacuum or process cases). Typically requires tight control of alignment and counterface quality. |

The Standard PS-SEAL is the starting point: one lip, a “base” material build-up, and intended as a robust upgrade versus elastomer oil seals. When you need additional functionality, you move to the Non-Standard versions. These mainly include lip configurations that solve a specific issue: an extra lip to block external contamination (PS-SEAL dustlip), a reversed lip direction when pressure/media comes from the other side (reverse PS-SEAL), a double arrangement for extra security/service life (tandem PS-SEAL), or an arrangement to seal in both directions or separate media (PS-SEAL back-to-back).

You start with the basic dimensions: shaft diameter (d), housing bore (D), and installation height/width (B). Then you verify fits and tolerances against common ISO practice (shaft and bore tolerances are genuinely important for this type of seal to achieve a stable press fit and predictable lip loading). Next, you evaluate the counterface critically: roughness, hardness, and “no spiral marks” are even more decisive for PTFE lips, especially as you move toward higher speed, higher pressure, or suboptimal lubrication.

You then link material selection to the process: for a typical, well-lubricated industrial duty the standard direction is often fine, while in food/pharma, vacuum/dry running, or abrasion you will more quickly move to a different lip variant. Finally, it is wise to always validate your choice against the real operating conditions (pressure, speed, temperature, and medium), because together they determine whether you mainly benefit from low friction and wear resistance, or whether you need an additional lip configuration or an alternative compound to run truly stable, with minimal leakage and maximum uptime.

In summary, Garlock PS-Seal Standard is a reliable and versatile sealing solution for rotating shafts. With its exceptional resistance to high pressure, extreme vacuum, chemical aggression, and wide temperature range, this seal ensures reliable performance in demanding applications. The use of Gylon as the sealing lip material further enhances the seal's capabilities, delivering effective sealing and increased uptime. Trust in Garlock's expertise and choose PS-Seal Standard for your shaft sealing needs.

Find all our other PS-Seals or our full range of Garlock Seals here!

When you need more margin at higher speed, (medium) high pressure, aggressive/abrasive media, or extreme temperatures, and your main goal is to increase reliability and service life.

In some applications yes, especially if you stay within the PS-SEAL’s operating range and want to avoid the complexity of a mechanical seal. For very high pressure or “zero leakage” requirements, a mechanical seal often remains the more logical choice.

Very important: PTFE lips are less forgiving than rubber. Proper roughness, sufficient hardness, and avoiding spiral marks help prevent leakage and accelerated wear.

Usually a food-grade variant (e.g., White/Blue/Brown-White/F), depending on cleaning regime, medium, speed, and any abrasion. The “standard” base design is not automatically the right choice for compliance.

It can be, but it depends strongly on lip material selection and counterface quality. In those cases you want a compound known for good dry-running properties and you need to keep pv loading under control.

Make sure d/D/B are correct, the press fit in the bore is reliable, and the shaft size and roundness are within common tolerances. If in doubt, it is smarter to validate the fit and counterface first than to install it “on a hunch.”

Didn't find the right PS-Seal (Standard)?

Complete the form below and we will help you!