| Product | Product Id | Type | Color | Material | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|

|

25765 | VA-1450 | Brown | FKM - FPM - Viton | 2 |

Request

|

Details | Quote |

|

25766 | VA-1500 | Brown | FKM - FPM - Viton | 2 |

Request

|

Details | Quote |

|

25774 | VA-150 | Brown | FKM - FPM - Viton | 4 | € 61,88 | Details | |

|

25775 | VA-50 | Brown | FKM - FPM - Viton | 1531 | € 11,38 | Details | |

|

25776 | VA-900 | Brown | FKM - FPM - Viton | 11 | € 871,44 | Details | |

|

25777 | VA-950 | Brown | FKM - FPM - Viton | 19 | € 915,35 | Details | |

|

25779 | VA-170 | Brown | FKM - FPM - Viton | 2 | € 80,82 | Details | |

|

25784 | VA-1550 | Brown | FKM - FPM - Viton | 2 |

Request

|

Details | Quote |

|

25785 | VA-1650 | Brown | FKM - FPM - Viton | 4 |

Request

|

Details | Quote |

|

25786 | VA-1950 | Brown | FKM - FPM - Viton | 2 |

Request

|

Details | Quote |

|

25788 | VA-100 | Brown | FKM - FPM - Viton | 966 | € 31,92 | Details | |

|

25794 | VA-400 | Brown | FKM - FPM - Viton | 94 | € 300,57 | Details | |

|

25795 | VA-220 | Brown | FKM - FPM - Viton | 704 | € 151,18 | Details | |

|

25796 | VA-180 | Brown | FKM - FPM - Viton | 87 | € 81,56 | Details | |

|

25798 | VA-70 | Brown | FKM - FPM - Viton | 763 | € 18,28 | Details | |

|

25799 | VA-75 | Brown | FKM - FPM - Viton | 4872 | € 23,38 | Details | |

|

25800 | VA-95 | Brown | FKM - FPM - Viton | 1915 | € 28,64 | Details | |

|

25802 | VA-1150 | Brown | FKM - FPM - Viton | 19 |

Request

|

Details | Quote |

|

25803 | VA-85 | Brown | FKM - FPM - Viton | 5 | € 21,90 | Details | |

|

25805 | VA-120 | Brown | FKM - FPM - Viton | 456 | € 50,94 | Details | |

|

25806 | VA-450 | Brown | FKM - FPM - Viton | 4 | € 331,10 | Details | |

|

25808 | VA-18 | Brown | FKM - FPM - Viton | 3955 | € 6,27 | Details | |

|

25812 | VA-25 | Brown | FKM - FPM - Viton | 806 | € 7,38 | Details | |

|

25814 | VA-60 | Brown | FKM - FPM - Viton | 2759 | € 16,08 | Details | |

|

25816 | VA-300 | Brown | FKM - FPM - Viton | 30 | € 193,35 | Details | |

|

25817 | VA-250 | Brown | FKM - FPM - Viton | 2 | € 155,93 | Details | |

|

25818 | VA-650 | Brown | FKM - FPM - Viton | 12 | € 528,50 | Details | |

|

25819 | VA-1200 | Brown | FKM - FPM - Viton | 2 |

Request

|

Details | Quote |

|

25820 | VA-200 | Brown | FKM - FPM - Viton | 64 | € 143,79 | Details | |

|

25821 | VA-375 | Brown | FKM - FPM - Viton | 1 | € 253,46 | Details |

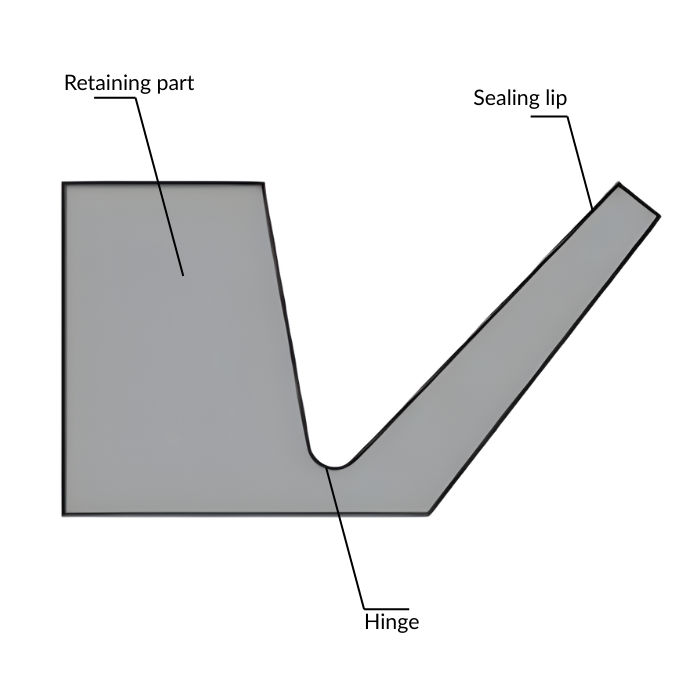

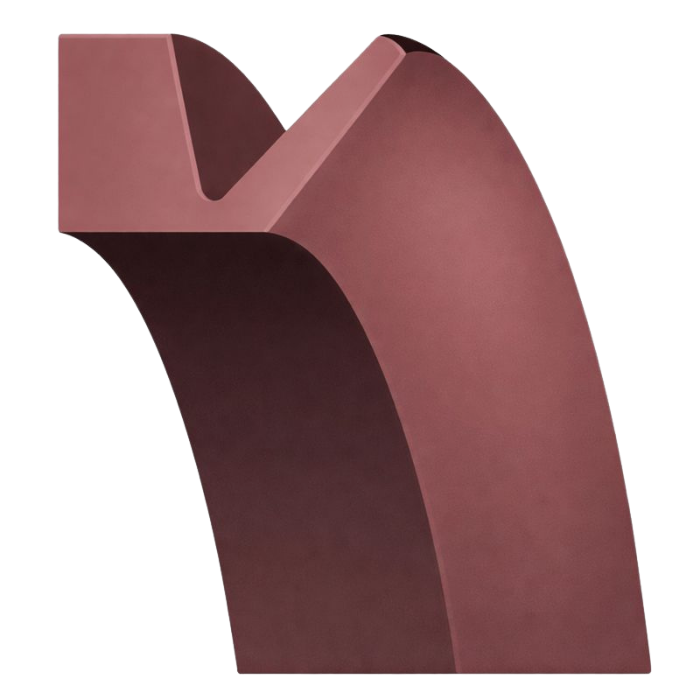

A V-ring A10 is made entirely of elastomer and has three recognizable zones: the retaining section that grips the shaft, the hinge point (the flexible transition) and the sealing lip. The A10 is the most commonly used standard design with a straight sealing back, which makes it compact and widely applicable. In this Viton version, the geometry and working principle remain the same, but the elastomer is selected for applications where higher temperature capability and improved resistance to many oils, fuels and chemicals are important. When the shaft is stationary, the lip presses against the counterface with a light initial contact pressure. That counterface can be “created” in different ways, for example by the housing itself, a housing cover, a pressed-in plate, the front of a roller bearing outer ring, or even the metal stiffening ring of a radial shaft seal.

As soon as the shaft starts to rotate, centrifugal force influences the behavior of the lip. Broadly speaking, friction losses first increase as circumferential speed rises (typically up to around 10 m/s), after which the contact pressure can decrease at higher speeds.

At very high circumferential speeds, the lip can (partly) experience “lift-off” (often mentioned around 15–20 m/s, depending on size, compound and conditions) and the V-ring increasingly acts as a gap seal and flinger disc. The sealing effect is therefore a combination of contact between the lip and the counterface and the flinging action caused by rotation, which actively throws water and contamination away from the sealing zone.

The V-ring A10 is widely used as a protective seal in situations where the outside of the machine is exposed to dirt, dust, mud, condensation or splash water. Think of electric motors, pumps and drives where bearings need to remain protected, but also gearboxes and general machinery where grease retention and contamination protection come together. The Viton A10 becomes especially relevant where these conditions combine with higher operating temperatures, hot surrounding components, or contact with oils, fuels or more chemically demanding media. In agricultural, construction and transport applications, the A10 is popular because it places low demands on shaft and housing machining, is relatively tolerant of minor coaxiality deviations or eccentricity, and is easy to install without a complex housing. This typically translates directly into less contamination in the bearing arrangement, a longer service life of the radial seal behind it, and less maintenance because both the V-ring and the primary seal generally last longer.

In the market, the A10 is commonly available in NBR and FKM, and in some cases also in EPDM (or other compounds) on request. This page focuses specifically on the Viton option, which is typically chosen when temperatures are higher or when you’re dealing with more chemically aggressive media than standard rubber compounds can comfortably handle. In many applications, FPM is valued for its aging resistance under heat and its broad resistance to oils, fuels and many chemicals, which helps the lip and retaining section stay stable over time. The trade-off is that this material family can be less flexible at low temperatures, and it is usually a more expensive choice than NBR. In practice, the selection logic is straightforward: if heat, oil/fuel exposure or chemical influence is a key driver, a Viton A10 is often the more reliable long-term option.

|

Material |

Typical temperature range |

Key properties (plus/min) |

|

FKM (Viton®) |

approx. -20 to +200 °C |

+ Very good at high temperature, broad chemical resistance, good aging resistance. – Less flexible at low temperatures, generally more expensive. |

The V-ring A10 (VA) is the most common standard profile and is known for its straight back and compact axial design, making it a solid all-round choice for general contamination protection and grease retention. If you need an even tighter grip on the shaft, the S10 V-ring (VS) profile is often preferred: it uses a conically extended retaining section, which helps it sit more securely in certain installations. When installation space is limited, the L10 V-ring (VL) profile is used because it has a smaller, more compact cross-section, designed specifically for tight axial spaces while keeping the same basic sealing principle. For very large shafts or heavier-duty conditions, the E10 V-ring (VE) can be relevant, as this one is typically selected for larger diameters and more demanding environments.

You determine the sizing of a V-ring A10 primarily based on the shaft diameter, because the ring grips the shaft through its own preload. So you choose the A10 that matches your nominal shaft size, not based on the outer diameter. Next, you look at the installation conditions: the shaft must be free of burrs, and a small chamfer helps prevent tearing or damage during installation. The counterface is at least as important, because the lip seals axially against it; the surface must be clean, flat and reasonably smooth, because deep scratches or burrs reduce service life and make the sealing action unstable.

If you expect higher circumferential speeds or a lot of vibration, it is advisable to provide an axial stop or retention so the ring cannot “creep” along the shaft. You then select the compound based on temperature (continuous and peak), medium (oil/grease, fuels, chemicals) and environment (outdoor, UV/ozone, abrasive contamination). In terms of standards and tolerances: V-rings are forgiving, but they are still molded rubber products with production tolerances. Therefore, design practically with sufficient margin, and focus mainly on the correct size on the shaft, a suitable counterface, and an elastomer choice that matches your operating conditions, where FKM/FPM is typically the step up when heat and media demand it.

|

Design |

anyseals |

Trelleborg |

Forsheda Stefa |

Dichtomatik |

Taiwan/China |

|

V-ring A10 / VA |

VR-A10 |

VA |

A |

VA |

VA |

In summary, the V-Ring A10 is a versatile rotary seal that provides effective shaft sealing by keeping out contaminants and preventing leakage. Its versatile application possibilities, low friction, high circumferential speeds, insensitivity to alignment, long lifespan, and ease of assembly make it a reliable choice for various industries and machinery types. Choose the V-Ring A10 for optimal shaft sealing performance and protection.

If you would like more information, of if you do not know which Ring you should have, feel free to contact us.

No. The A10 is essentially a protective seal (excluder) against external contamination and can support grease retention, but it is not intended to hold system pressure.

The A10/VA is the standard version with a straight sealing back. The S10/VS has a conically extended retaining section and therefore often sits more securely on the shaft.

Yes, this is a very common combination. The V-ring acts as a pre-seal and protects the radial oil seal and the bearing arrangement from dirt and water from the outside.

This can be, for example, the housing itself, a housing cover, a pressed-in plate, the front of a roller bearing outer ring, or the metal stiffening ring of a radial shaft seal. The key is that the surface is clean, flat and free of burrs.

If oil or grease is present, NBR is usually the logical starting point. At higher temperature or with more aggressive media, Viton (FKM/FPM) is often better. With water/weather without oil, EPDM can be suitable.

Prevent damage when sliding it on (burr-free and preferably with a chamfer), make sure the ring is not twisted or kinked, and check that the lip runs neatly and evenly on the counterface. At higher speeds, an axial stop or additional retention is advisable.

Didn't find the right VA FKM?

Complete the form below and we will help you!