| Product | Product Id | Type | Color | Material | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|

|

26191 | VL-900 | Brown | FKM - FPM - Viton | 0 | € 408,42 | Details | Quote |

|

26192 | VL-950 | Brown | FKM - FPM - Viton | 0 | € 416,92 | Details | Quote |

|

26193 | VL-725 | Brown | FKM - FPM - Viton | 0 | € 379,67 | Details | Quote |

|

26194 | VL-1000 | Brown | FKM - FPM - Viton | 0 | € 425,43 | Details | Quote |

|

26195 | VL-1400 | Brown | FKM - FPM - Viton | 0 |

Request

|

Details | Quote |

|

26196 | VL-1850 | Brown | FKM - FPM - Viton | 0 |

Request

|

Details | Quote |

|

26197 | VL-1150 | Brown | FKM - FPM - Viton | 0 |

Request

|

Details | Quote |

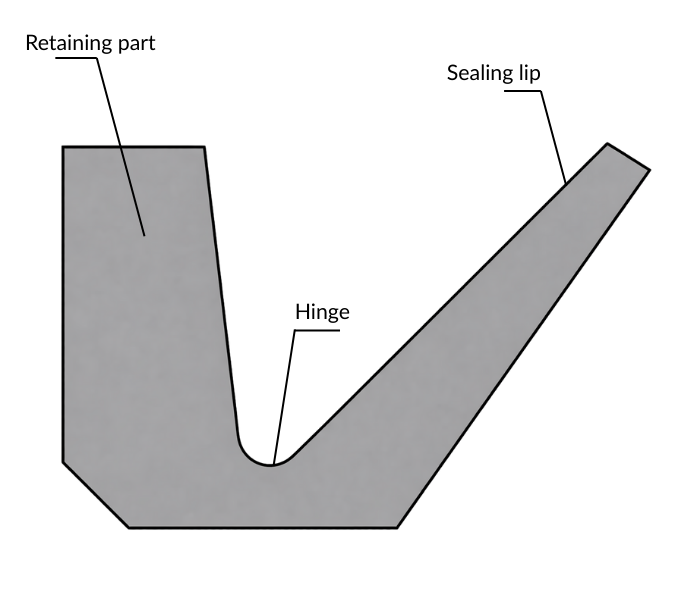

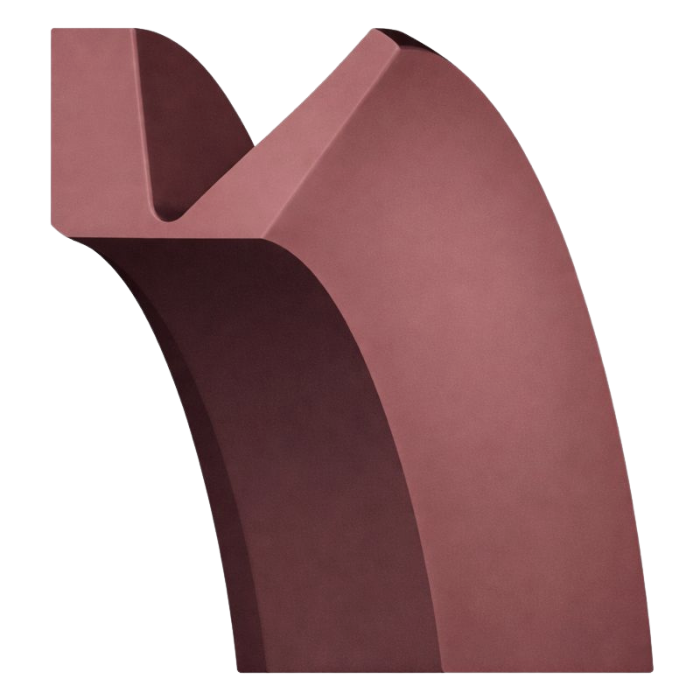

A V-ring L10 is made entirely of elastomer. The V-profile consists of a relatively solid retaining section that clamps onto the shaft and a flexible sealing lip, which are connected via a hinge zone. That hinge zone is the bend point of the V and ensures that the lip can flex smoothly and absorb small misalignment errors. The L10 stands out mainly because of its compact profile geometry and the fact that this profile remains uniform across all diameters. Instead of becoming “larger and more robust” at larger shaft diameters, the basic shape of the L10 remains comparable, which makes it pleasantly predictable in design and ideal in situations where you have little axial space.

During operation, the L10 works in two ways. When stationary and at low to medium speeds, the lip rests against the counterface with an initial contact pressure, providing contact sealing. As circumferential speed increases, centrifugal force influences the lip pressure and the contact pressure decreases.

At around 15–20 m/s, the lip begins to lift from the counterface and the contact pressure drops toward zero. In that range, the ring functions more as a gap seal and flinger disc, with very low friction. Up to about 10 m/s, friction losses generally increase, after which they decrease again at higher speeds.

You mainly see the V-ring L10 where external contamination is the biggest enemy and where you want to keep the primary seal or the bearing as clean as possible for as long as possible. Think of bearing shields and bearing housings as a pre-seal, electric motors and drives in dusty environments, gearboxes and transmission units that operate outdoors or in wet conditions, and pumps or rotating units where splash water, cleaning or condensation plays a role. The L10 is also a practical solution in agricultural and construction machinery, where mud and dust are continuously present. Precisely because it is compact, it often still fits in places where a standard V-ring profile requires too much installation length. This gives you a simple additional barrier against dirt and water, without immediately making the design more complex.

This VL page focuses specifically on the Viton option (often specified as FKM or FPM). You typically choose this compound family when temperatures are higher, when you expect more aggressive media, or when you want better ageing stability in outdoor installations where ozone and weather exposure play a role. Compared to standard nitrile compounds, FPM generally maintains its properties better under heat and offers broad resistance to many oils, fuels and chemicals, which helps keep lip behavior stable over time.

The trade-offs are also important: FKM compounds are usually less favorable at lower temperatures (reduced flexibility) and are generally chosen when you actually need the extra resistance rather than as a default. In other words: if heat, chemical exposure, fuel contact, or harsh outdoor ageing is part of your operating reality, a Viton L10 is often the more reliable long-term choice.

|

Material |

Temp. range (guideline) |

Key properties (keywords) |

|

FKM 60 (Viton®) |

–20 to +200 °C |

high T · chemicals · ozone/weather/ageing · outdoor use · less at low T |

The A10 V-ring is the standard V-ring you see in most applications: a widely applicable profile with a straight back that is mainly intended as a pre-seal to keep dirt, dust and splash water out and to protect a bearing or radial shaft seal. The S10 V-ring follows the same sealing principle, but has a conically extended retaining section. As a result, in practice it often sits slightly more securely on the shaft and is more interesting if you are concerned about “creeping” due to vibration, varying load or higher speeds. L10 was developed for compact installation situations: the profile is smaller and remains uniform across diameters, so you need less axial space while still keeping the same function as a pre-seal and flinger/splash protection. The E10 V-ring is an alternative design that does not fall under the standard A/S/L profiles and is often supplied on request. You mainly choose E10 when the standard profiles do not work well geometrically or when your supplier recommends a heavier/differently shaped V-ring for a more robust setup. In short: A10 is the safe all-rounder, S10 is the “extra grip” variant, L10 is the compact choice, and E10 is the design you choose when you are better served by a different geometry or a heavier execution.

The choice starts with the shaft diameter, because the V-ring is stretched over the shaft and must clamp by inherent tension. It is important not to make the stretch greater than necessary: the more you stretch the ring, the higher the contact force of the lip against the counterface becomes, which can increase friction and wear. That is why you preferably choose a size that falls within the recommended range values of the size table and keeps the stretch as limited as possible. You then select the compound based on temperature and medium; Viton is logical for higher temperatures, outdoor installations, or more aggressive media where standard compounds can age faster or lose stability.

Then comes the counterface, because that is where the dynamic sealing takes place. The flatness and roughness of that surface largely determine service life and the behaviour of the lip. Datasheets provide guideline values for this, where liquid media combined with higher circumferential speeds require a much smoother surface than sealing against grease and dust at lower speeds. The material of the counterface also matters: common steels, stainless steels or cast materials are generally suitable, but for water or corrosive media a protected surface or stainless steel is often more sensible. Finally, you look at operating condition and speed. In some situations it is wise to provide a simple axial stop or retention, so that the ring does not “creep” axially at higher speeds or with minimal stretch. At very high speeds, additional radial retention can also be relevant, depending on compound and preload. If you design according to the manufacturer’s size tables, tolerances and installation recommendations, you will usually be in a good place quickly.

|

Design / Type |

Anyseals |

Trelleborg |

Forsheda / Stefa |

Dichtomatik |

Taiwan / China |

|

V-ring L10 |

VR-L10 |

VL |

L |

VL |

VL |

In summary, the V-Ring L10 is a compact profile rotary seal designed for efficient sealing in compact installation situations. Its purpose is to effectively seal rotating shafts, preventing the ingress of contaminants and leakage of grease. With its compact profile geometry, the V-Ring L10 provides reliable sealing performance while minimizing space requirements. Trust in the V-Ring L10 for efficient and effective sealing solutions in compact applications.

If you would like more information, of if you do not know which Ring you should have, feel free to contact us.

No. The L10 is primarily a pre-seal against dirt, dust and water and retains grease only to a limited extent. For pressure sealing you use other sealing principles.

The L10 has a more compact profile with less installation length and a uniform profile across diameters. The A10 is the standard profile and is often the first choice when space is not an issue.

When stationary and at lower speeds, the lip seals with contact pressure against the counterface. As circumferential speed increases, that pressure decreases and at around 15–20 m/s the lip can begin to lift, causing the ring to work more as a gap seal and flinger disc with low friction.

You choose it for higher temperatures, more chemical exposure, fuel contact, or when ozone/weather resistance and ageing stability are important.

Very important, because that is where the dynamic sealing takes place. A flat counterface with an appropriate roughness reduces wear and keeps the sealing function stable, especially at higher speeds or with liquid media.

That is possible in some designs, but then the lip pressure does not decrease with increasing speed due to centrifugal force. This generally results in higher friction and can reduce service life somewhat compared to the standard co-rotating installation.

Didn't find the right VL FKM?

Complete the form below and we will help you!