| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Spring | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

77164 | Oil Seal | 240 | 210 | 13 | NBR - Nitrile | Yes | Black | 136 | € 41,82 | Details | ||

|

77178 | Oil Seal | 254 | 230 | 10 | FPM - VITON | Yes | Brown | 113 |

Request

|

Details | Quote | |

|

77177 | Oil Seal | 215 | 185 | 15 | FPM - VITON | Yes | Brown | 27 |

Request

|

Details | Quote | |

|

77176 | Oil Seal | 170 | 140 | 13 | FPM - VITON | Yes | Brown | 0 |

Request

|

Details | Quote | |

|

77175 | Oil Seal | 165.1 | 142.88 | 11.11 | FPM - VITON | Yes | Brown | 19 |

Request

|

Details | Quote | |

|

77174 | Oil Seal | 150 | 130 | 13 | FPM - VITON | Yes | Brown | 82 |

Request

|

Details | Quote | |

|

77173 | Oil Seal | 145 | 125 | 13 | FPM - VITON | Yes | Brown | 76 |

Request

|

Details | Quote | |

|

77172 | Oil Seal | 140 | 120 | 13 | FPM - VITON | Yes | Brown | 244 |

Request

|

Details | Quote | |

|

77171 | Oil Seal | 140 | 110 | 14 | FPM - VITON | Yes | Brown | 54 |

Request

|

Details | Quote | |

|

77170 | Oil Seal | 120 | 95 | 11 | FPM - VITON | Yes | Brown | 28 |

Request

|

Details | Quote | |

|

77169 | Oil Seal | 110 | 85 | 13 | FPM - VITON | Yes | Brown | 174 |

Request

|

Details | Quote | |

|

77168 | Oil Seal | 80 | 60 | 11 | FPM - VITON | Yes | Brown | 179 |

Request

|

Details | Quote | |

|

77167 | Oil Seal | 50 | 33 | 10 | FPM - VITON | Yes | Brown | 162 |

Request

|

Details | Quote | |

|

77166 | Oil Seal | 320 | 295 | 10 | NBR - Nitrile | Yes | Black | 63 | € 98,86 | Details | ||

|

77165 | Oil Seal | 254 | 230 | 10 | NBR - Nitrile | Yes | Black | 8 | € 54,50 | Details | ||

|

77179 | Oil Seal | 320 | 295 | 10 | FPM - VITON | Yes | Brown | 12 |

Request

|

Details | Quote | |

|

77163 | Oil Seal | 220 | 190 | 13 | NBR - Nitrile | Yes | Black | 105 | € 29,92 | Details | ||

|

77162 | Oil Seal | 215 | 185 | 15 | NBR - Nitrile | Yes | Black | 0 | € 29,92 | Details | Quote | |

|

77161 | Oil Seal | 180 | 155 | 10 | NBR - Nitrile | Yes | Black | 248 | € 20,27 | Details | ||

|

77160 | Oil Seal | 175 | 160 | 9 | NBR - Nitrile | Yes | Black | 28 | € 20,27 | Details | ||

|

77159 | Oil Seal | 175 | 145 | 14 | NBR - Nitrile | Yes | Black | 39 | € 21,62 | Details | ||

|

77158 | Oil Seal | 170 | 140 | 13 | NBR - Nitrile | Yes | Black | 379 | € 21,26 | Details | ||

|

77157 | Oil Seal | 170 | 124 | 14.5 | NBR - Nitrile | Yes | Black | 594 | € 19,35 | Details | ||

|

77156 | Oil Seal | 165.1 | 127 | 11.13 | NBR - Nitrile | Yes | Black | 99 | € 20,03 | Details | ||

|

77155 | Oil Seal | 160 | 125 | 13 | NBR - Nitrile | Yes | Black | 292 | € 19,35 | Details | ||

|

77154 | Oil Seal | 160 | 120 | 15 | NBR - Nitrile | Yes | Black | 124 | € 18,64 | Details | ||

|

77153 | Oil Seal | 150 | 130 | 13 | NBR - Nitrile | Yes | Black | 0 | € 20,03 | Details | Quote | |

|

77152 | Oil Seal | 140 | 120 | 13 | NBR - Nitrile | Yes | Black | 0 | € 18,64 | Details | Quote | |

|

77151 | Oil Seal | 140 | 105 | 15 | NBR - Nitrile | Yes | Black | 154 | € 15,12 | Details | ||

|

77150 | Oil Seal | 132 | 105 | 13 | NBR - Nitrile | Yes | Black | 77 | € 15,12 | Details |

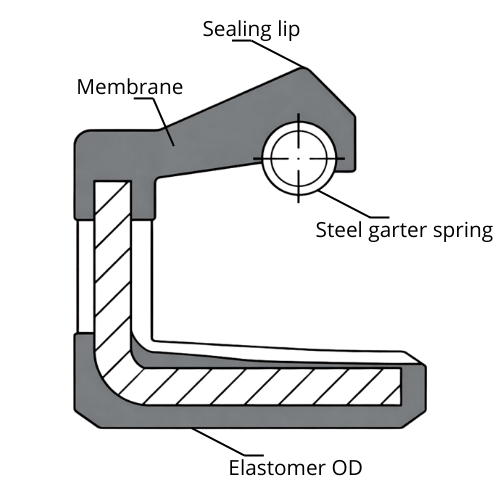

In terms of design, the O18 is very similar to an SC oil seal, but with a mirrored lip design for outside sealing. The seal has a single spring-loaded sealing lip, a steel reinforcement ring and a smooth rubber outer jacket that provides a reliable static seal in the housing and compensates for small deviations in form and surface roughness. As standard, it is manufactured in NBR 70 black with spring steel according to DIN EN 10270-1 and sheet steel according to DIN EN 10139. The design is tailored to unpressurised applications up to around 0.05 MPa, a temperature range from –40 °C to +100 °C (preferably below 80 °C for a long service life) and circumferential speeds of up to approximately 10 m/s. The lip is oriented towards the outside: the spring side faces the medium you want to keep inside, while the sealing line prevents leakage to the outside and the rubber outer jacket helps prevent fretting corrosion.

The O18 is mainly used in applications where two media must be kept strictly separated or where a medium must not leak to the outside in designs with a stationary shaft and a rotating housing, hub or drum. The seal is mounted on the shaft and seals towards the outside, functionally acting as the mirror image of an SC seal in a stationary housing. Typical examples include bearing chambers filled with oil next to a compartment containing coolant or process fluid, as well as special drives, gearboxes and pumps in relatively clean industrial environments. The O18 keeps the lubricant clean and prevents media from mixing, but because it has no dust lip it is less suitable for heavy contamination with mud, sand or water. In shielded housings, the single lip performs very efficiently and with low friction.

The typical oil seal O18 is made of NBR 70, which has excellent resistance against mineral oils and greases and is a reliable option in most industrial applications up to approximately +100 °C. If the temperature is higher or there are synthetic oils, fuels or chemically loaded fluids present, then FKM is a logical next choice due to its heat and chemical resistance, while HNBR provides an intermediate option with a higher mechanical strength and higher ageing resistance than standard NBR. For specific applications, materials like Silicone, ACM, CR or EPDM are available on request. Silicone performs excellent at lower temperatures but is mechanically less robust, while EPDM is particularly suitable for hot water, steam and brake fluids without oil. In practice, you’ll always begin with identifying the medium and operating temperature and then choose an elastomer that offers the best chemical and thermal match.

|

Material |

Temperature range |

Key properties |

|

NBR |

–40 °C to +100 °C |

mineral oils/greases, wear-resistant, low cost, mediocre at heat/ozone/synthetic |

|

HNBR |

–30 °C to +150 °C |

high strength, better heat/ozone, chemical resistance, modern lubricants |

|

FKM |

–20 °C to +150/180 °C |

high temperature, chemically resistant, fuels, synthetic oils, stiff in cold |

|

VMQ (silicone) |

–50 °C to +180 °C |

extreme cold, wide temperature range, flexible, low mechanical strength |

|

ACM |

–20 °C to +150 °C |

engine/transmission oil, heat-resistant, oxidation-stable, weaker in humid conditions |

|

CR |

–30 °C to +110 °C |

oil- and weather-resistant, good ageing, niche alternative |

|

EPDM |

–40 °C to +140 °C |

hot water, steam, brake fluid, excellent ozone/weather resistance, not oil-resistant |

Structurally, the O18 and the SC oil seal are very similar: both are single-acting radial shaft seals with a spring-loaded lip and an elastomer-sheathed outer diameter, without a dust lip. The SC is used for inside sealing in a stationary housing around a rotating shaft, while the O18 has been developed for outside sealing in designs with a stationary shaft and a rotating housing or hub. In practice, you can therefore see the O18 as the functional opposite of the SC, which you deliberately select as soon as you need an external seal around a stationary shaft .

Choosing the right O18 oil seal starts with the dimensions: the inner diameter must match the shaft diameter, the outer diameter the housing diameter and the width the available installation space. You then check fit and surface finish: for the shaft, ISO H11 is preferred with a minimum hardness of around 45 HRC and a fine, torsion-free ground surface (approximately Ra 0.2–0.8 µm), and for the housing ISO H8 with a roughness around Ra 1.6–6.3 µm. The rubber outer jacket makes the O18 slightly more forgiving than a seal with a metal outer diameter.

Once the geometry is correct, you select the material based on the operating medium and temperature, choosing from NBR, FKM, HNBR or one of the special materials listed above. Keep in mind that the O18 is designed for non-pressurised applications up to around 0.05 MPa and circumferential speeds up to about 10 m/s; above these limits, wear increases rapidly and you are more likely to end up with special high-speed or PTFE-based seals. In heavily contaminated outdoor environments, an O18 without dust lip is less suitable and a model with dust lip or an additional wiper is usually the better option, whereas in relatively clean, shielded housings it is a very efficient solution for outside sealing and media separation.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

Only if the sealing scenario matches. The SC is intended for inside sealing (rotating shaft, stationary housing), whereas the O18 is specifically designed for outside sealing, often on a stationary shaft with a rotating housing. Always first check which component rotates and in which direction you need to seal.

No, the O18 is designed for non-pressurised or lightly pressurised applications up to around 0.05 MPa. For true high-pressure applications you need a special high-pressure seal or a different sealing concept.

For standard oil and grease applications, NBR is usually the best choice. At higher temperatures or when working with synthetic oils and fuels, you will quickly end up with FKM or HNBR. Always start from the medium and the temperature and then choose the elastomer.

An overly rough shaft damages the sealing lip and increases the risk of leakage. If the shaft is too soft (below approx. 45 HRC), the running surface wears in quickly and the seal loses its preload. In both cases, the service life of the O18 decreases significantly.

Didn't find the right Oil Seal O18 - Rotary Shaft Seal?

Complete the form below and we will help you!