| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

74058 | Oil Seal | 18 | 32 | 7 | PTFE | SS-316 | Black | 3 | € 39,98 | Details | ||

|

71911 | Oil Seal | 65 | 90 | 10 | PTFE | SS-316 | Black | 2 | € 97,70 | Details | ||

|

71912 | Oil Seal | 170 | 200 | 15 | PTFE | SS-316 | Black | 3 | € 173,42 | Details | ||

|

71913 | Oil Seal | 62 | 85 | 8 | PTFE | SS-316 | Black | 0 | € 97,70 | Details | Quote | |

|

71914 | Oil Seal | 58 | 80 | 10 | PTFE | SS-316 | Black | 25 | € 99,94 | Details | ||

|

71917 | Oil Seal | 107 | 130 | 13 | PTFE | SS-316 | Black | 0 | € 157,01 | Details | Quote | |

|

71922 | Oil Seal | 10 | 22 | 7 | PTFE | SS-316 | Black | 425 | € 35,60 | Details | ||

|

71923 | Oil Seal | 40 | 62 | 7 | PTFE | SS-316 | Black | 15 | € 66,44 | Details | ||

|

71924 | Oil Seal | 48 | 62 | 8 | PTFE | SS-316 | Black | 20 | € 66,44 | Details | ||

|

71926 | Oil Seal | 230 | 260 | 15 | PTFE | SS-316 | Black | 0 | € 264,31 | Details | Quote | |

|

71930 | Oil Seal | 65 | 85 | 10 | PTFE | SS-316 | Black | 0 | € 97,70 | Details | Quote | |

|

71931 | Oil Seal | 60 | 110 | 12 | PTFE | SS-316 | Black | 0 | € 129,82 | Details | Quote | |

|

71932 | Oil Seal | 90 | 160 | 12 | PTFE | SS-316 | Black | 0 | € 129,82 | Details | Quote | |

|

71940 | Oil Seal | 30 | 62 | 7 | PTFE | SS-316 | Black | 17 | € 45,22 | Details | ||

|

73817 | Oil Seal | 58 | 80 | 8 | PTFE | SS-316 | Black | 5 | € 99,94 | Details | ||

|

73819 | Oil Seal | 130 | 150 | 18 | PTFE | SS-316 | Black | 0 | € 141,85 | Details | Quote | |

|

73820 | Oil Seal | 75 | 95 | 12 | PTFE | SS-316 | Black | 10 | € 99,98 | Details | ||

|

73821 | Oil Seal | 50 | 65 | 7 | PTFE | SS-316 | Black | 3 | € 69,96 | Details | ||

|

73822 | Oil Seal | 75 | 95 | 8 | PTFE | SS-316 | Black | 24 | € 99,98 | Details | ||

|

73825 | Oil Seal | 170 | 200 | 12 | PTFE | SS-316 | Black | 5 | € 294,95 | Details | ||

|

73826 | Oil Seal | 60 | 80 | 8 | PTFE | SS-316 | Black | 14 | € 85,36 | Details | ||

|

73828 | Oil Seal | 45 | 65 | 10 | PTFE | SS-316 | Black | 0 | € 66,44 | Details | Quote | |

|

73829 | Oil Seal | 40 | 60 | 10 | PTFE | SS-316 | Black | 0 | € 66,44 | Details | Quote | |

|

73830 | Oil Seal | 145 | 170 | 12 | PTFE | SS-316 | Black | 0 | € 152,77 | Details | Quote | |

|

73831 | Oil Seal | 35 | 47 | 7 | PTFE | SS-316 | Black | 0 | € 52,36 | Details | Quote | |

|

73840 | Oil Seal | 80 | 110 | 10 | PTFE | SS-316 | Black | 5 | € 122,37 | Details | ||

|

73845 | Oil Seal | 85 | 110 | 12 | PTFE | SS-316 | Black | 10 | € 129,82 | Details | ||

|

73850 | Oil Seal | 560 | 610 | 20 | PTFE | SS-316 | Black | 0 |

Request

|

Details | Quote | |

|

73855 | Oil Seal | 110 | 140 | 12 | PTFE | SS-316 | Black | 26 | € 157,01 | Details | ||

|

73856 | Oil Seal | 148 | 170 | 14.5 | PTFE | SS-316 | Black | 0 | € 152,77 | Details | Quote |

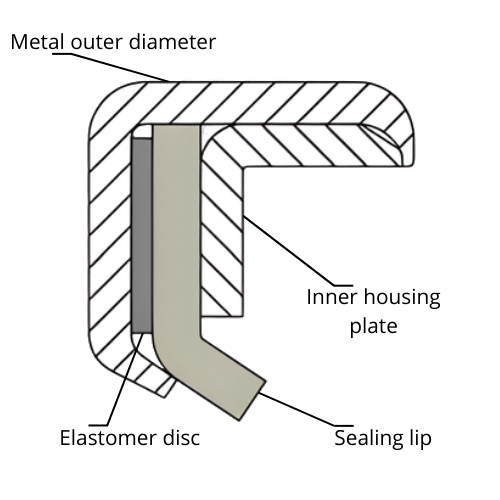

The PA31 oil seal consists of a metal outer housing that is mounted into the bore via a metal-to-metal press fit. Inside this housing is a PTFE sealing lip, which is mechanically retained and supported by an elastomer disc, typically made of FKM. This elastomer disc is clamped between two housing plates and acts as an energizer, thereby taking over the function of a traditional garter spring.

During operation, this construction ensures that the PTFE lip is continuously and evenly pressed against the rotating shaft. Thanks to the low coefficient of friction of PTFE, stable running behaviour without stick-slip is achieved, even at high circumferential speeds. At the same time, the seal remains dimensionally stable under pressure, preventing the lip from folding over or being pushed away as can occur with conventional rubber oil seals. This makes the oil seal PA31 suitable for applications with internal overpressure up to approximately 1 MPa and high thermal load. Depending on the operating conditions, the PA31 oil seal is suitable for circumferential speeds of up to approximately 40 m/s.

The PA31 oil seal is mainly used in industrial environments where reliability under demanding conditions is essential. In the chemical industry, this type of seal is applied because of its excellent resistance to aggressive media and high temperatures. Within machine and equipment construction, for example in pumps, mixers, and compressors, the oil seal PA31 also provides a durable sealing solution at high speeds and under fluctuating loads.

In addition, the PA31 rotary shaft seal is widely used in drive technology, such as gearboxes and industrial drives where low friction, minimal wear, and long service life are important. The combination of pressure resistance, thermal stability, and chemical resistance makes this oil seal particularly suitable for applications in which conventional sealing solutions prove insufficiently reliable.

The PA31 oil seal is available in various material combinations, allowing it to be adapted to specific operating conditions. In the standard version, the sealing lip is made of PTFE filled with glass fiber and MoS₂. This composition provides a good balance between wear resistance, dimensional stability, and low friction. The housing is usually made of corrosion- and acid-resistant steel (1.4404 / AISI 316L), ensuring high corrosion resistance in aggressive environments. The elastomer disc is typically made of FKM, due to its good temperature resistance and chemical stability. The oil seal PA31 is compatible with mineral oil-based lubricants, synthetic lubricants, water, and a wide range of acids, alkalis, and solvents.

For specific applications, alternative material combinations are available. For example, a PTFE sealing lip with carbon-graphite can be selected when extremely high temperatures or prolonged dry running are involved. In less aggressive environments, a standard steel housing can be a cost-effective alternative to stainless steel. Other elastomers for the energizer are also available on request, for example when specific media or temperature ranges are required. When selecting materials, it is important to always consider temperature, pressure, circumferential speed, and medium in combination.

The permissible maximum values must always be evaluated in relation to all operating parameters, as the total load on the seal results from the combined conditions.

|

Material component |

Temperature range (indicative) |

Main properties |

|

PTFE sealing lip (glass fiber / MoS₂) |

-90 °C to +250 °C |

Very low friction, high wear resistance, pressure-resistant, stable at high circumferential speeds, good dimensional stability, suitable for insufficient lubrication and dry running |

|

PTFE sealing lip (carbon-graphite) |

-90 °C to +250 °C |

Even lower friction than glass fiber-filled PTFE, very suitable for high temperatures and prolonged dry running, excellent thermal stability |

|

Elastomer disc (FKM) |

approx. -20 °C to +200 °C |

Good temperature resistance, high chemical resistance, stable energizer function for the PTFE lip |

|

Elastomer disc (alternative elastomers) |

Depending on material |

Can be adapted to specific media, temperatures, or chemical exposure |

|

Housing (stainless steel 1.4404 / AISI 316L) |

– |

Excellent corrosion and chemical resistance, suitable for aggressive environments |

|

Housing (carbon steel) |

– |

Cost-effective alternative for non-corrosive applications |

Selecting the correct PA31 oil seal starts with determining the correct shaft and housing dimensions. The shaft must comply with ISO h11 tolerances and have a minimum hardness of 50 HRC, combined with a very fine and torsion-free surface finish. This is essential to limit wear of the PTFE lip and to ensure stable sealing performance. Compliance with the specified surface roughness values is critical to prevent premature wear of the PTFE sealing lip and to ensure stable sealing performance. The housing must be manufactured according to ISO H8 tolerances and have a suitable surface roughness to achieve a reliable press fit.

In addition to dimensions, operating conditions also play an important role. Temperature, pressure, circumferential speed, and the medium to be sealed largely determine which material combination is most suitable. Because the oil seal PA31 is produced independently of molds, special sizes and small series are also possible without high tooling costs, providing flexibility for specific applications.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

Yes, the oil seal PA31 is specifically designed for pressure-loaded applications and can withstand internal pressures of up to approximately 1 MPa when correctly installed.

Thanks to the PTFE sealing lip, the PA31 oil seal can tolerate short periods of dry running, although adequate lubrication remains important for maximum service life.

No, the sealing pressure is provided by an elastomer disc that supports the PTFE lip, making a spring unnecessary.

Yes, the combination of PTFE and a stainless-steel housing makes this oil seal suitable for many acids, alkalis, solvents, and various types of lubricants.

This is possible, but with light metals and rougher bores it is often recommended to use a sealing aid on the outer diameter.

Didn't find the right Oil Seal PA31 - Rotary Shaft Seal?

Complete the form below and we will help you!