| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

53731 | Oil Seal | 52.38 | 64.29 | 4.76 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53730 | Oil Seal | 50.8 | 69.85 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 503 | € 1,85 | Details | ||

|

53729 | Oil Seal | 49.21 | 89.99 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,88 | Details | Quote | |

|

53728 | Oil Seal | 49.21 | 82.55 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,66 | Details | Quote | |

|

53727 | Oil Seal | 49.21 | 79.37 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 325 | € 2,35 | Details | ||

|

53726 | Oil Seal | 49.21 | 76.2 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,35 | Details | Quote | |

|

53725 | Oil Seal | 49.21 | 73.02 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,89 | Details | Quote | |

|

53724 | Oil Seal | 49.21 | 69.85 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote | |

|

53723 | Oil Seal | 49.21 | 68.26 | 9.52 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote | |

|

53722 | Oil Seal | 49.21 | 68.26 | 7.72 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote | |

|

53721 | Oil Seal | 48.08 | 61.82 | 6.35 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53720 | Oil Seal | 47.62 | 73.02 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,89 | Details | Quote | |

|

53719 | Oil Seal | 47.62 | 68.26 | 9.52 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote | |

|

53718 | Oil Seal | 47.62 | 63.5 | 9.52 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53717 | Oil Seal | 47.62 | 63.5 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 1340 | € 4,98 | Details | ||

|

53716 | Oil Seal | 46.03 | 73.11 | 9.22 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,89 | Details | Quote | |

|

53715 | Oil Seal | 46.03 | 69.85 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote | |

|

53714 | Oil Seal | 44.45 | 89.99 | 11.11 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,88 | Details | Quote | |

|

53713 | Oil Seal | 44.45 | 84.53 | 11.11 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,66 | Details | Quote | |

|

53712 | Oil Seal | 44.45 | 80.09 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,66 | Details | Quote | |

|

53711 | Oil Seal | 44.45 | 76.2 | 9.52 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,35 | Details | Quote | |

|

53710 | Oil Seal | 44.45 | 76.2 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 2,35 | Details | Quote | |

|

53709 | Oil Seal | 44.45 | 73.02 | 11.91 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,89 | Details | Quote | |

|

53708 | Oil Seal | 44.45 | 63.65 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53707 | Oil Seal | 44.45 | 63.5 | 9.52 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53706 | Oil Seal | 44.45 | 60.32 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53705 | Oil Seal | 44.45 | 60.32 | 11.11 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,59 | Details | Quote | |

|

53704 | Oil Seal | 44.45 | 59.13 | 11.11 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,48 | Details | Quote | |

|

53703 | Oil Seal | 44.45 | 50.8 | 7.93 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,25 | Details | Quote | |

|

53702 | Oil Seal | 44.04 | 69.24 | 12.7 | NBR - Nitrile | Steel | Steel | Yes | Black | 0 | € 1,85 | Details | Quote |

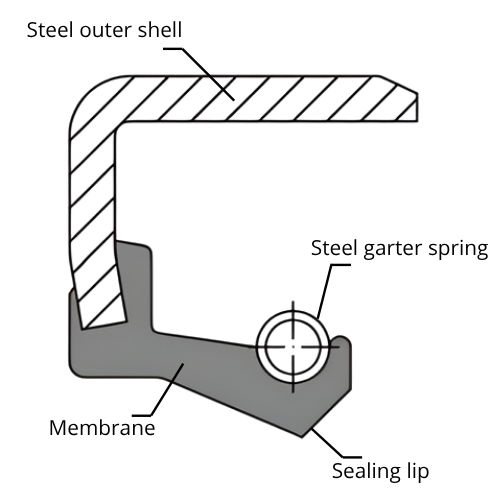

The SB oil seal is a rotary shaft seal which consists of a steel outer shell. The elastomer sealing lip together with the internal steel garter spring reinforces radial pressure on the rotating shaft. This design makes the rotary shaft seal extremely reliable and stable during operations while keeping friction and heat generation low. Its steel outer diameter guarantees a stable press-fit, avoiding rotation or axial displacement during service. Sealing performance can be enhanced by pairing the SB type rotor seal with RB axial seals or V-rings, especially in dirty or splash-heavy environments. Due to it’s simple yet durable design, the oil seal SB is used a lot in a variety of mechanical systems requiring a reliable sealing. Other profiles, such as the SC oil seal or the TC oil seal, offer a rubber outer diameter or a dual-lip sealing. The oil seal SB on the other side focusses mainly on maximum structural rigidity and a clean dynamic sealing.

The SB oil seal is commonly found in gearboxes, electric motors, hydraulic drives, PTO units, industrial pumps and general machinery. In agricultural and construction equipment, its steel-cased design prevents twisting or displacement when exposed to heavy shock loads. For applications requiring a more solid contamination protection, the oil seal TB offers the same steel-cased design as the SB but with an additional dust lip. In industrial power transmission, the oil seal SB design is preferred when a stable metal-to-metal fit is required for a rotary shaft seal. When a completely closed inner metal side is needed, there's the SA type rotary shaft seal which provides added strength and protection against internal contamination.

To match your oil seal SB perfectly to your specific operating conditions, the rotary shaft seal can be produced in a variety of elastomer materials. The most common one you’ll find is NBR. This material offers excellent resistance to standard lubricating oils and fits most of general rotary shaft seal applications. When the SB oil seal will be in touch with higher temperatures of aggressive lubricants, FKM (Viton®) will be the preferred choice. That’s because it’s very reliable if it comes to heat and chemical resistance. HNBR is an option which provides a stronger and more wear-resistant alternative when it comes to mechanical environments where shock, abrasion or fluctuating loads are present.

Automotive systems that experience elevated temperatures but still rely on oil compatibility often benefit from ACM, this is a material which is optimized for long-term performance in hot oil environments. On the other hand, VMQ (Silicone) is selected flexibility across extreme low or high temperatures is needed, though this material is less suited for heavy mechanical loads. And at last, there is EPDM. This material is used in applications involving coolants, steam or water-based media, situations where oil is not the primary fluid being sealed.

To ensure that your oil seal SB type delivers a reliable sealing, longer service life and a reduced wear on both the lip and the shaft, it’s very important to choose the right material.

Below you’ll find a table providing information about the most common compounds used for oil seals SB and their typical operating ranges.

|

Material |

Temp. range |

Characteristics |

Typical Use |

|

NBR (Nitrile) |

–40°C to +100°C |

Excellent oil resistance, cost-effective |

Standard SB oil seal |

|

FKM (Viton®) |

up to +200°C |

High-temperature & chemical resistance |

High-speed rotary shaft seal applications |

|

ACM |

up to +150°C |

Heat- and oil-resistant |

Automotive environments |

|

VMQ (Silicone) |

–50°C to +180°C |

Very flexible in cold/heat extremes |

Low-load shafts, ventilation units |

|

EPDM |

up to +120°C |

Resistant to coolants & steam |

Water-based media (non-oil) |

To ensure a long and reliable service life of your SB oil seals, the shaft surface must be smooth. It must have a smooth surface (Ra 0.2-0.8 µm), be hardened to at least 45HRC and free from spiral machining marks that could cause oil pumping outward. The housing should meet H8 tolerances and have a clean, lightly roughened finish to support stable press-fitting of the metal outer diameter. Before you install the rotary shaft seal, you must first apply a thin layer of lubricant to the sealing lip to prevent dry start-up. It's best to use a flat pressing tool that contacts only the outer case, allowing the SB oil seal to enter the bore evenly without deformation. The spring side should always face towards the lubricant.

A lot of manufacturers use different naming systems for their equivalent of the SB oil seals. This table helps identify matching profiles across brands.

|

Manufacturer / Brand |

Equivalent Name |

|

Dichtomatik |

WB |

|

Anyseals |

OS-B10 |

|

B+S |

TR-C |

|

Chicago R |

CRW1 |

|

Elring |

B |

|

ERIKS |

M |

|

FP Paris |

L1 |

|

FST |

B1 |

|

Gaco |

ABI |

|

Goetze |

822 N |

|

Kaco |

DF |

|

Kramp |

BB |

|

National |

48 |

|

Paulstra |

EE |

|

Pioneer W |

R4 |

|

Rolf |

RM |

|

Stefa |

BB |

|

Taiwan / NOK |

SB |

|

Vota |

B1 |

|

Ebele |

B1 |

|

Kimman |

KB |

The SB oil seal has a complete steel outer shell, while the SC seal uses a rubber-coated OD. SB is preferred for metal housings requiring precise press-fit and mechanical stability.

Only low pressure. The oil seal SB is designed for applications up to approx. 0.5 bar. Higher pressure requires specialized high-pressure seals.

Yes, especially in FKM material. The steel OD maintains housing stability in high-speed rotor seal environments.

Choose FKM when the rotary shaft seal must withstand elevated temperatures, aggressive lubricants or high peripheral speeds.

Yes, the TB rotary shaft seal (same metal OD but with an added dust lip) is used when dirt exclusion is crucial.

Didn't find the right Oil Seal SB - Rotary Shaft Seal?

Complete the form below and we will help you!