| Product | Product Id | Type | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Color | Garlock Number | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

32145 | Garlock PS Seal | 18 | 35 | 8 | GYLON F | SS 316 | Off White/Blue | MEC04-12776 | 0 |

Request

|

Details | Quote |

|

32144 | Garlock PS Seal | 17 | 35 | 8 | GYLON F | SS 316 | Off White/Blue | MEC04-13742 | 0 | € 145,60 | Details | Quote |

|

32125 | Garlock PS Seal | 150 | 180 | 12 | GYLON F | SS 316 | Off White/Blue | MEC04-14132 | 0 | € 667,42 | Details | Quote |

|

32124 | Garlock PS Seal | 25 | 52 | 8 | GYLON F | SS 316 | Off White/Blue | MEC04-13743 | 0 | € 319,42 | Details | Quote |

|

31072 | Garlock PS Seal | 65 | 80 | 10 | GYLON | SS 316 | Blue | MEC04-14442 | 0 | € 227,98 | Details | Quote |

|

30392 | Garlock PS Seal | 15 | 35 | 12 | GYLON | SS 316 | Black/Blue | MEC05-10541 | 0 |

Request

|

Details | Quote |

|

30387 | Garlock PS Seal | 225 | 270 | 15 | GYLON | SS 316 | Black | MEC05-10795 | 0 |

Request

|

Details | Quote |

|

30372 | Garlock PS Seal | 181 | 215 | 20 | GYLON | SS 316 | Black | MEC05-10533 | 0 |

Request

|

Details | Quote |

|

30370 | Garlock PS Seal | 180 | 215 | 15 | GYLON | SS 316 | Black | MEC05-10625 | 0 |

Request

|

Details | Quote |

|

30369 | Garlock PS Seal | 180 | 214 | 20 | GYLON KF | SS 316 | Black | MEC05-10785 | 0 |

Request

|

Details | Quote |

|

30368 | Garlock PS Seal | 180 | 210 | 30 | GYLON | SS 316 | Black | MEC05-10549 | 0 |

Request

|

Details | Quote |

|

30069 | Garlock PS Seal | 90 | 110 | 12.5 | GYLON | SS 316 | White | MEC05-10385 | 0 |

Request

|

Details | Quote |

|

30068 | Garlock PS Seal | 70 | 100 | 17 | GYLON | SS 316 | White | MEC05-10408 | 0 |

Request

|

Details | Quote |

|

30062 | Garlock PS Seal | 160 | 190 | 15 | GYLON F | SS 316 | Off White/Blue | MEC05-10638 | 0 |

Request

|

Details | Quote |

|

30034 | Garlock PS Seal | 17 | 37 | 12 | GYLON F | SS 316 | Off White/Blue | MEC05-10341 | 0 |

Request

|

Details | Quote |

|

30030 | Garlock PS Seal | 145 | 175 | 30 | GYLON F | SS 316 | Off White | MEC05-10646 | 0 |

Request

|

Details | Quote |

|

30028 | Garlock PS Seal | 130 | 160 | 12 | GYLON F | SS 316 | Off White | MEC05-10639 | 0 |

Request

|

Details | Quote |

|

30025 | Garlock PS Seal | 110 | 140 | 18 | GYLON F | SS 316 | Off White | MEC05-10562 | 0 |

Request

|

Details | Quote |

|

30003 | Garlock PS Seal | 17.78 | 50.8 | 14 | GYLON F | SS 316 | Off White | MEC05-10899 | 0 |

Request

|

Details | Quote |

|

30001 | Garlock PS Seal | 240 | 270 | 16 | GYLON | SS 316 | Blue | MEC05-10612 | 0 |

Request

|

Details | Quote |

|

29999 | Garlock PS Seal | 210 | 240 | 16 | GYLON | SS 316 | Blue | MEC05-10610 | 0 |

Request

|

Details | Quote |

|

29998 | Garlock PS Seal | 190 | 224 | 20 | GYLON | SS 316 | Blue | MEC05-10915 | 0 |

Request

|

Details | Quote |

|

29996 | Garlock PS Seal | 175 | 205 | 15 | GYLON | SS 316 | Blue | MEC05-10805 | 0 |

Request

|

Details | Quote |

|

29994 | Garlock PS Seal | 160 | 194 | 20 | GYLON | SS 316 | Blue | MEC05-10351 | 0 |

Request

|

Details | Quote |

|

29992 | Garlock PS Seal | 150 | 184 | 20 | GYLON | SS 316 | Blue | MEC05-10563 | 0 |

Request

|

Details | Quote |

|

29990 | Garlock PS Seal | 135 | 170 | 12 | GYLON | SS 316 | Blue | MEC05-10902 | 0 |

Request

|

Details | Quote |

|

29986 | Garlock PS Seal | 120 | 150 | 15 | GYLON | SS 316 | Blue | MEC05-10832 | 0 |

Request

|

Details | Quote |

|

29985 | Garlock PS Seal | 120 | 146 | 15 | GYLON | SS 316 | Blue | MEC05-10495 | 0 |

Request

|

Details | Quote |

|

29981 | Garlock PS Seal | 95 | 110 | 12.5 | GYLON | SS 316 | Blue | MEC05-10864 | 0 |

Request

|

Details | Quote |

|

29976 | Garlock PS Seal | 80 | 110 | 17 | GYLON | SS 316 | Blue | MEC05-10350 | 0 |

Request

|

Details | Quote |

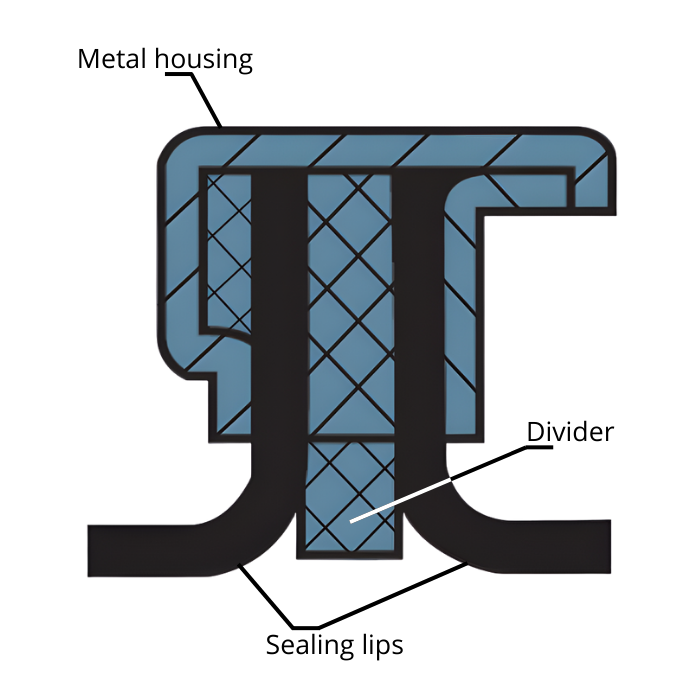

Back-to-back is designated by Garlock as an official Non-Standard lip configuration. The seal is built around a metal housing (seal case), for which Garlock specifies stainless steel 1.4571 as the standard material, with alternatives available on request. The actual sealing element is a GYLON® lip, i.e., a modified PTFE material, selected for its combination of low friction, chemical inertness, and a broadly applicable temperature range. Because the back-to-back variant falls within Non-Standard, it is built within the Non-Standard framework of the PS-SEAL line; this means the configuration is in principle available in the same size ranges as the standard PS-SEAL, but the shaft diameter and the width can be adjusted to a limited extent when the application requires it.

Garlock positions the PS-SEAL as a solution for rotating applications where high circumferential speed, higher pressure, extreme temperatures, or a combination of aggressive and abrasive media present a challenge for conventional oil seals. In that context, the back-to-back version also fits: you choose this Non-Standard configuration when, within the same PS-SEAL technology, you deliberately need a different lip arrangement than the standard version. The datasheet also presents the PS-SEAL as an alternative to mechanical seals and braided packings in certain applications, precisely because the combination of PTFE-based lip materials and the PS-SEAL design can be a robust, maintenance-friendly solution in specific cases.

Garlock directly links PS-SEAL performance to the selected lip material and mentions several GYLON® compounds that are also relevant for Non-Standard configurations (such as back-to-back). GYLON® Black is the standard material and is especially logical in lubricated applications due to its stable, low-friction behavior. For food, pharma, and beverage applications, Garlock mentions GYLON® White and GYLON® Blue with FDA and EN 1935 compliance; White is partly suitable for dry running, while Blue is recommended when dry running is important and you want extra flexibility and recovery. F-econol is also FDA/EN 1935 compliant and is interesting when, in addition to dry running, you also need suitability for vacuum. For abrasive duty, Garlock mentions MS (MoS₂) and KF (carbon fiber), with KF offering a good combination for partially abrasive media with good dry running properties. Garlock emphasizes that dry running makes the requirements for the counterface and shaft condition more critical, because tribology then becomes more decisive for service life and sealing performance.

|

Material |

Temp range (guideline) |

Important properties |

|

GYLON® Black (seal lip) |

approx. −90 °C to +260 °C |

Standard compound; best for lubricated duties; low-friction and stable. |

|

GYLON® White (seal lip) |

approx. −90 °C to +260 °C |

FDA + EN 1935 compliant; recommended for food/pharma/beverage; partly suitable for dry running. |

|

GYLON® Blue (seal lip) |

approx. −90 °C to +260 °C |

FDA + EN 1935 compliant; high flexibility/recovery; strong dry-running performance. |

|

F-econol (seal lip) |

approx. −90 °C to +260 °C |

FDA + EN 1935 compliant; relevant for vacuum duty; strong dry-running performance. |

|

MS (MoS₂) (seal lip) |

approx. −90 °C to +260 °C |

Intended for abrasive media (improved wear resistance). |

|

KF (carbon fiber) (seal lip) |

approx. −90 °C to +260 °C |

For partly abrasive media; good dry-running properties. |

|

Stainless steel 1.4571 (seal case) |

n/a (housing) |

Standard metal case; robust and corrosion resistant (other materials on request). |

Size selection starts with shaft and bore dimensions, with the note that the PS-SEAL Back-to-Back falls under PS-SEAL Non-Standard. Garlock indicates that Non-Standard configurations are in principle available in the same sizes as PS-SEAL Standard, with the possibility to vary d1 and B slightly, and cites bore Ø H7 and shaft Ø h11 as the baseline fits. Material selection then follows from the medium, lubrication condition, temperature, and load: Garlock specifies −90 °C to +260 °C for the lip materials, noting that frictional heat can raise the seal temperature above the process temperature. For pressure, Non-Standard can, depending on the version, go up to 25 bar; at higher pressure Garlock recommends a p×v check and axial fixation. The counterface is also crucial: Garlock specifies Ra 0.1–0.4 μm, Rz 0.6–2.0 μm, and Rmax 4 μm and warns against helical/spiral marks due to the pumping effect and leakage risk. As a guideline, Garlock specifies a shaft hardness of 60 HRC, and for p×v > 20 bar·m/s a chromium oxide coating is recommended. Finally, with combinations of higher pressure and higher circumferential speed, the limits must always be verified, because that combination determines sealing durability.

Within the Garlock® PS-SEAL family, the Back-to-Back is especially interesting when you deliberately need a Non-Standard lip configuration rather than the standard build-up. PS-SEAL Standard is the most straightforward choice for single-sided sealing and is often used as an upgrade from a conventional elastomer oil seal, but with the typical PTFE/GYLON benefits. The Reverse Lip PS-SEAL is a better fit when hygiene and cleanability are priorities and you want to limit dead spaces on the product side. Single Lip with Dust Lip PS-SEAL focuses on extra protection against external contamination, so dust or dirt puts less load on the working sealing point. You choose PS-SEAL Tandem when you want two sealing points in the same direction for extra security or service life, while Back-to-Back is more appropriate when, within the same PS-SEAL technology, you need a different sealing logic than standard or tandem.

In summary, Garlock PS-Seal Back to Back is a reliable and versatile sealing solution for rotating shafts. With its exceptional resistance to high pressure, extreme vacuum, chemical aggression, and wide temperature range, this seal ensures reliable performance in demanding applications. The use of Gylon as the sealing lip material further enhances the seal's capabilities, delivering effective sealing and increased uptime. Trust in Garlock's expertise and choose PS-Seal Back to Back for your shaft sealing needs.

Find all our other PS-Seals or our full range of Garlock Seals here!!

Back-to-back is designated by Garlock as an official PS-SEAL Non-Standard lip configuration. It refers to the 2 seals that are positioned “Back-to-Back”.

According to the datasheet, this version falls under PS-SEAL Non-Standard and can, depending on the version, go up to 25 bar; at higher pressure Garlock recommends a p×v check and axial fixation.

Garlock specifies a range of −90 °C to +260 °C for the lip materials, noting that frictional heat can increase the seal temperature.

Garlock mentions GYLON® White, GYLON® Blue, and F-econol as FDA and EN 1935 compliant options and recommends them for food/pharma/beverage.

Garlock specifies Ra 0.1–0.4 μm, Rz 0.6–2.0 μm, Rmax 4 μm, no spiral marks, and a guideline value of 60 HRC; for p×v > 20 bar·m/s a chromium oxide coating is recommended.

Didn't find the right PS-Seal (Back to Back)?

Complete the form below and we will help you!