| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

71363 | Oil Seal | 260 | 300 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 154,64 | Details | Quote | |

|

71378 | Oil Seal | 735 | 799 | 25 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 755,10 | Details | Quote | |

|

71377 | Oil Seal | 600 | 650 | 25 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 523,00 | Details | Quote | |

|

71376 | Oil Seal | 530 | 580 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 514,44 | Details | Quote | |

|

71375 | Oil Seal | 500 | 540 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 378,64 | Details | Quote | |

|

71374 | Oil Seal | 480 | 530 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 439,12 | Details | Quote | |

|

71373 | Oil Seal | 470 | 520 | 25 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 352,03 | Details | Quote | |

|

71372 | Oil Seal | 400 | 444 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 274,95 | Details | Quote | |

|

71371 | Oil Seal | 380 | 420 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 245,49 | Details | Quote | |

|

71370 | Oil Seal | 360 | 404 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 235,58 | Details | Quote | |

|

71369 | Oil Seal | 340 | 380 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 208,11 | Details | Quote | |

|

71368 | Oil Seal | 330 | 374 | 19 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 208,54 | Details | Quote | |

|

71367 | Oil Seal | 330 | 370 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 200,56 | Details | Quote | |

|

71366 | Oil Seal | 310 | 350 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 185,75 | Details | Quote | |

|

71365 | Oil Seal | 290 | 334 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 178,81 | Details | Quote | |

|

71364 | Oil Seal | 260 | 304 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 159,67 | Details | Quote | |

|

71379 | Oil Seal | 780 | 830 | 25 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 808,35 | Details | Quote | |

|

71362 | Oil Seal | 220 | 260 | 16 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 156,08 | Details | Quote | |

|

71361 | Oil Seal | 220 | 250 | 15 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 150,43 | Details | Quote | |

|

71360 | Oil Seal | 190 | 220 | 16 | NBR - Nitrile | SS-304 | Yes | No | Black | 4 | € 136,80 | Details | ||

|

71359 | Oil Seal | 165 | 190 | 15 | NBR - Nitrile | SS-304 | Yes | No | Black | 1 | € 121,09 | Details | ||

|

71358 | Oil Seal | 140 | 155 | 10 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 108,58 | Details | Quote | |

|

71357 | Oil Seal | 120 | 150 | 13 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 104,05 | Details | Quote | |

|

71340 | Oil Seal | 780 | 820 | 18 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 791,83 | Details | Quote | |

|

71337 | Oil Seal | 600 | 650 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 523,36 | Details | Quote | |

|

71336 | Oil Seal | 450 | 500 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 328,36 | Details | Quote | |

|

71327 | Oil Seal | 500 | 550 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 391,19 | Details | Quote | |

|

71323 | Oil Seal | 430 | 480 | 22 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 306,78 | Details | Quote | |

|

71296 | Oil Seal | 390 | 434 | 20 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 264,81 | Details | Quote | |

|

71266 | Oil Seal | 170 | 200 | 15 | NBR - Nitrile | SS-304 | Yes | No | Black | 0 | € 126,32 | Details | Quote |

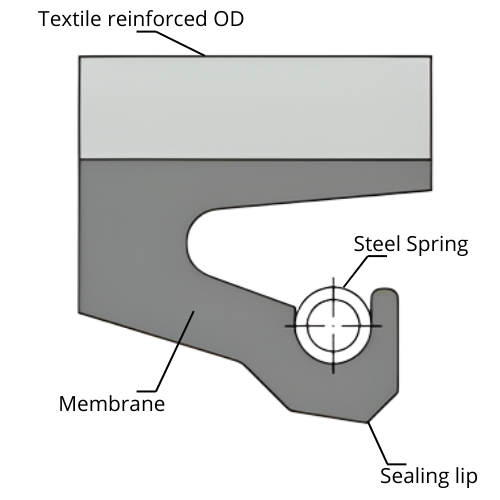

The oil Seal Q10 belongs to the category of textile reinforced oil seals and consists of multiple parts which keep the seal durable and stabile together. The sealing lip, that’s made of NBR, FKM or HNBR, forms the first barrier against leakage. A garter spring keeps constant radial pressure on the sealing lip, which helps maintaining the lubrication between the lip and the shaft. It also helps to keep friction controlled. Around the sealing lip is the outer diameter. This OD is made of rubber that’s reinforced with a layer of textile. That’s a crucial part of the Q10 oil seal, because it gives the seal stiffness, helps it hold its shape and ensures a secure press-fit inside the housing, even if the bore shows minor wear or expands under heat. Thanks to its reinforced design, the Q10 rotary shaft seal stays correctly positioned even when exposed to dirt, abrasive particles, minor shaft runout or mechanical vibration. The Q10 is designed for a temperature range of –30°C to +100°C, circumferential speeds up to approximately 20 m/s and internal pressures up to around 0.05 MPa when used under balanced operating conditions.

Due to the different suppliers and manufacturers, which all have their own names/codes for the oil seal, the Q10 rotary shaft seal is also known for the codes/names shown in the cross-reference table below:

|

Fabrikant / Leverancier |

Cross-Reference Codes |

|

Anyseals |

OS-Q10 |

|

Dichta |

D5 |

|

AC |

GW-5, GW-6, GW-7 |

|

FP |

TGU, TGA, TGR |

|

JM Clipper |

LPD, LPDW, LUP, LUPW, RUP, RUPW, MIST |

|

Carco |

Carcoseal |

|

Garlock |

Klozure 151-1, 151-2, 154-1, 154-2 |

|

Eriks |

WR5, G35 |

|

James Walker |

Walkersele D1, D1/DL, D6, D6/DL |

|

SKF |

HFS, HFSA |

The used material strongly influences how a Q10 oil seal performs. NBR (nitrile rubber) is the most common option, suitable for general industrial applications and temperatures up to around 100°C. A standard Q10 configuration typically includes an 80-shore NBR lip, an NBR-impregnated cotton fabric reinforcement and a stainless-steel 1.4310 garter spring to ensure long-term elasticity. It also offers a good balance between cost efficiency, oil resistance and mechanical performance.

For higher temperatures or chemical demanding environments, FKM is a preferred material. This material stays elastic up to around 200°C and shows excellent resistance against aggressive oils and fuels. In gearboxes or drivers with high oil-temperatures, the Q10 oil seal made of FKM is the standard.

When extreme wear resistance or stability under vibration is required, HNBR is the commonly used material. This material is tougher, more wear-resistant, and offers better tear resistance. That’s why the Q10 rotary shaft seal made of HNBR is used a lot in agriculture machines, construction equipment and other installations where dirt, moisture, dust and abrasive slurries are present.

All functional components of the Q10, including the spring and fabric layer, are corrosion-resistant, which improves reliability in humid or chemically exposed environments.

|

Material |

Temperature Range |

Key Properties |

Typical Applications |

|

NBR |

–30°C to +100°C |

Good oil resistance, economical, low compression set |

General industry, pumps, motors, gearboxes |

|

FKM (Viton) |

–20°C to +200°C |

Excellent heat and chemical resistance |

High-temperature drives, chemical exposure, heavy-duty gearboxes |

|

HNBR |

–20°C to +150°C |

Highly wear-resistant, ozone-resistant, vibration-stable |

Agriculture, abrasive media, high-load rotating systems |

Each Q10 oil seal has a fabric reinforced OD that adds stiffness, improves the housing fit and increases service life compared to seal with a standard rubber OD.

The Q10 rotary shaft seals are used in situations where a standard seal loses its form or isn’t stable enough under load. In pumps and electromotors, they offer a reliable sealing to retain oil and keep moisture and slurries out. In larger industrial gearboxes, the oil seal Q10 maintains dimensional stability and sealing performance even during thermal cycling or variably loading. The Q10 is also widely used in ship-building, rolling mills, wind turbines and large industrial gear systems where high loads and fluctuating temperatures are common.

In agriculture machinery, the rotary shaft seal Q10 type stands out because of its resistance to dust, mud and abrasive contaminants. Heavy equipment such as conveyors, loaders and crushers benefits from the reinforced structure, which handles vibration, misalignment and fluctuating loads far better than a standard seal. In hydraulic drives and exposed industrial shafts, Q10 oil seals retain their form and sealing performance significantly longer than traditional NBR shaft seals.

In comparison to a standard oil seal NBR with an elastomer OD, the Q10 oil seal offers several distinct advantages. The textile reinforced outer shell provides greater stiffness, creating a more stable press-fit in the housing. This reduces micro-movement and prevents the oil seal from rotating in the bore. The textile-reinforced OD can compensate for minor bore imperfections, allowing the Q10 to seal effectively even in housings with increased surface roughness. The result is a longer lifespan and less chance on leakage. The oil seal Q10 performs better in dirty of abrasive environments. The lip remains stable even when dust or grit is present, minimising leakage and delaying wear. Its structure is highly resistant to vibration, especially when fitted with an HNBR lip. Although the rubber-fabric oil seal is not a high-pressure oil seal, it handles slight pressure in low-pressure systems better than standard rubber OD seals. Finally, the oil seal Q10 is particularly suitable for large diameters because the reinforced construction prevents deformation and keeps the seal stable, even when the housing expands due to heat.

While choosing the right Q10 fabric reinforced rotary shaft seal, there are 3 dimentions you should keep in mind: the shaft diameter, the housing or bore diameter, and the width of the seal. Most Q10 oil seals follow standard DIN and ISO sizing for rotary shaft seals, making them interchangeable with standard types when tolerances are met.

Using a size filter or size table helps you find the right size combination. For larger diameters or unusual housings, it’s wise to check the bore tolerance carefully. Because the reinforced OD creates a firmer fit than a soft rubber OD, correct installation space is more important.

For optimal performance, the shaft should follow ISO h tolerances with a hardness of at least 60 HRC and a surface finish between Ra 0.2–0.8 µm, while the housing should follow ISO H8 with a recommended roughness of Ra 1.6–4 µm.

A Q10 oil seal is a radial shaft seal with a rubber sealing lip and a textile reinforced outer shell. This design offers more stability, wear resistance and dimensional rigidity than a standard seal.

An oil seal Q10 type is suitable when a conventional seal fails due to dirt, vibration, misalignment or heavy loading. It is specifically engineered for demanding conditions.

No, Q10 seals are not intended for high-pressure applications. They do, however, tolerate slight pressure better than standard rubber OD designs.

Didn't find the right Oil Seal Q10 - Rotary Shaft Seal?

Complete the form below and we will help you!