| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

35254 | Oil Seal | 18 | 32 | 4.5 | NBR - Nitrile | Carbon steel according to DIN EN 13214 | Spring steel according to DIN EN 10270-3076 | Yes | No | Black | 412 | € 1,34 | Details | ||

|

35255 | Oil Seal | 18.9 | 28 | 5 | NBR - Nitrile | Carbon steel according to DIN EN 13215 | Spring steel according to DIN EN 10270-3077 | Yes | No | Black | 0 | € 0,68 | Details | Quote | |

|

35256 | Oil Seal | 19 | 21 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13216 | Spring steel according to DIN EN 10270-3078 | Yes | No | Black | 0 | € 0,63 | Details | Quote | |

|

35257 | Oil Seal | 19 | 28 | 5 | NBR - Nitrile | Carbon steel according to DIN EN 13217 | Spring steel according to DIN EN 10270-3079 | Yes | No | Black | 0 | € 0,68 | Details | Quote | |

|

35258 | Oil Seal | 19 | 36 | 6.5 | NBR - Nitrile | Carbon steel according to DIN EN 13218 | Spring steel according to DIN EN 10270-3080 | Yes | No | Black | 0 | € 0,91 | Details | Quote | |

|

35259 | Oil Seal | 19 | 41 | 8 | NBR - Nitrile | Carbon steel according to DIN EN 13219 | Spring steel according to DIN EN 10270-3081 | Yes | No | Black | 0 | € 1,00 | Details | Quote | |

|

35260 | Oil Seal | 19.7 | 35 | 6.4 | NBR - Nitrile | Carbon steel according to DIN EN 13220 | Spring steel according to DIN EN 10270-3082 | Yes | No | Black | 0 | € 0,80 | Details | Quote | |

|

35261 | Oil Seal | 20 | 28 | 4 | NBR - Nitrile | Carbon steel according to DIN EN 13221 | Spring steel according to DIN EN 10270-3083 | Yes | No | Black | 113 | € 0,73 | Details | ||

|

35262 | Oil Seal | 20 | 40 | 4 | NBR - Nitrile | Carbon steel according to DIN EN 13222 | Spring steel according to DIN EN 10270-3084 | Yes | No | Black | 2300 | € 2,22 | Details | ||

|

35263 | Oil Seal | 20 | 40 | 8 | NBR - Nitrile | Carbon steel according to DIN EN 13223 | Spring steel according to DIN EN 10270-3085 | Yes | No | Black | 1085 | € 0,91 | Details | ||

|

35264 | Oil Seal | 20 | 42 | 5 | NBR - Nitrile | Carbon steel according to DIN EN 13224 | Spring steel according to DIN EN 10270-3086 | Yes | No | Black | 0 | € 1,00 | Details | Quote | |

|

35265 | Oil Seal | 20 | 42 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13225 | Spring steel according to DIN EN 10270-3087 | Yes | No | Black | 2142 | € 3,71 | Details | ||

|

35266 | Oil Seal | 20 | 45 | 7 | NBR - Nitrile | Carbon steel according to DIN EN 13226 | Spring steel according to DIN EN 10270-3088 | Yes | No | Black | 1466 | € 1,00 | Details | ||

|

35267 | Oil Seal | 20 | 47 | 4 | NBR - Nitrile | Carbon steel according to DIN EN 13227 | Spring steel according to DIN EN 10270-3089 | Yes | No | Black | 889 | € 1,11 | Details | ||

|

35268 | Oil Seal | 20 | 50 | 12 | NBR - Nitrile | Carbon steel according to DIN EN 13228 | Spring steel according to DIN EN 10270-3090 | Yes | No | Black | 0 | € 1,11 | Details | Quote | |

|

35269 | Oil Seal | 21 | 35 | 6.5 | NBR - Nitrile | Carbon steel according to DIN EN 13229 | Spring steel according to DIN EN 10270-3091 | Yes | No | Black | 1413 | € 2,23 | Details | ||

|

35270 | Oil Seal | 21 | 40 | 7 | NBR - Nitrile | Carbon steel according to DIN EN 13230 | Spring steel according to DIN EN 10270-3092 | Yes | No | Black | 878 | € 0,91 | Details | ||

|

35271 | Oil Seal | 21.9 | 47 | 8 | NBR - Nitrile | Carbon steel according to DIN EN 13231 | Spring steel according to DIN EN 10270-3093 | Yes | No | Black | 0 | € 1,11 | Details | Quote | |

|

35272 | Oil Seal | 22 | 29 | 4 | NBR - Nitrile | Carbon steel according to DIN EN 13232 | Spring steel according to DIN EN 10270-3094 | Yes | No | Black | 0 | € 0,68 | Details | Quote | |

|

35273 | Oil Seal | 22 | 30 | 4 | NBR - Nitrile | Carbon steel according to DIN EN 13233 | Spring steel according to DIN EN 10270-3095 | Yes | No | Black | 0 | € 0,68 | Details | Quote | |

|

35274 | Oil Seal | 22 | 35 | 5 | NBR - Nitrile | Carbon steel according to DIN EN 13234 | Spring steel according to DIN EN 10270-3096 | Yes | No | Black | 1576 | € 1,80 | Details | ||

|

35275 | Oil Seal | 23 | 40 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13235 | Spring steel according to DIN EN 10270-3097 | Yes | No | Black | 464 | € 0,91 | Details | ||

|

35276 | Oil Seal | 23.5 | 43.5 | 4.5 | NBR - Nitrile | Carbon steel according to DIN EN 13236 | Spring steel according to DIN EN 10270-3098 | Yes | No | Black | 0 | € 1,00 | Details | Quote | |

|

35277 | Oil Seal | 24 | 34 | 7 | NBR - Nitrile | Carbon steel according to DIN EN 13237 | Spring steel according to DIN EN 10270-3099 | Yes | No | Black | 0 | € 0,80 | Details | Quote | |

|

35278 | Oil Seal | 24 | 35 | 5.5 | NBR - Nitrile | Carbon steel according to DIN EN 13238 | Spring steel according to DIN EN 10270-3100 | Yes | No | Black | 0 | € 0,80 | Details | Quote | |

|

35279 | Oil Seal | 24 | 41 | 10 | NBR - Nitrile | Carbon steel according to DIN EN 13239 | Spring steel according to DIN EN 10270-3101 | Yes | No | Black | 0 | € 1,00 | Details | Quote | |

|

35280 | Oil Seal | 25 | 35 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13240 | Spring steel according to DIN EN 10270-3102 | Yes | No | Black | 1176 | € 0,80 | Details | ||

|

35281 | Oil Seal | 25 | 36 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13241 | Spring steel according to DIN EN 10270-3103 | Yes | No | Black | 0 | € 0,91 | Details | Quote | |

|

35282 | Oil Seal | 25 | 38 | 6 | NBR - Nitrile | Carbon steel according to DIN EN 13242 | Spring steel according to DIN EN 10270-3104 | Yes | No | Black | 401 | € 3,24 | Details | ||

|

35283 | Oil Seal | 25 | 42 | 9.7 | NBR - Nitrile | Carbon steel according to DIN EN 13243 | Spring steel according to DIN EN 10270-3105 | Yes | No | Black | 0 | € 2,96 | Details | Quote |

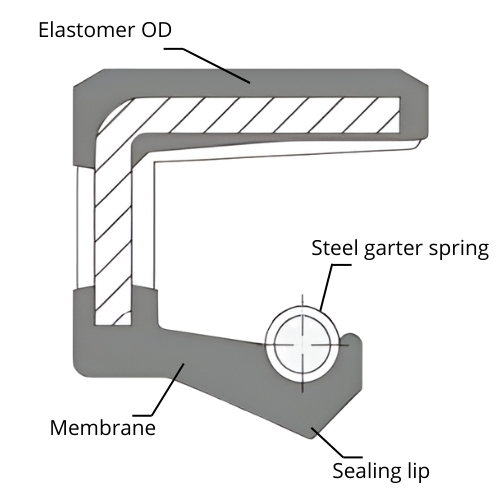

The SC oil seal is a rotary shaft seal with an elastomer coated outer diameter. To keep a consistent sealing, there is a steel garter spring which keeps the main sealing lip in contact with the rotating shaft. This design is called a “spring-loaded lip” and it’s made to keep constant radial pressure over a longer period. The rubber coated outside of the SC oil seal ensures a tight press fit into the house bore and is available in a variety of elastomers. Unlike the TC oil seals, which incorporates a secondary dust lip for added exclusion capability, the SC oil seals focus solely on fluid retention. Their streamlined design reduces friction, heat generation, and material cost, making them the ideal solution for controlled environments where external contaminants are limited. SC rotary shaft seals are ideal for thin-body lubricants and certain gaseous media when pressure limits remain within the specified operating range. Because of their simple single-lip geometry, they generate less heat and friction compared to dual-lip profiles, which benefits high-speed or energy-efficient systems.

SC shaft seals are best suited for clean operational environments, such as:

Their compact form factor and lower friction make SC oil seals advantageous in applications prioritizing efficiency, low torque, or space constraints. When dust, mud, or abrasive particles are not a concern, SC seals offer long-lasting performance with minimal complexity.

SC rotary shaft seals are available in various elastomer types tailored to specific media and temperature demands. Below is a comparison of common compounds and their operating properties:

|

Material |

Temperature Range |

Media Compatibility |

Notes |

|

NBR |

-40°C to +100°C |

Mineral oils, greases, water |

General-purpose; most cost-effective |

|

FKM |

-25°C to +200°C |

Synthetic oils, fuels, aggressive chemicals |

Excellent chemical resistance |

|

HNBR |

-30°C to +150°C |

Oils, coolants, ozone |

Good dynamic sealing properties |

|

VMQ |

-60°C to +200°C |

Food-grade, dry air, ozone |

Silicone-based; low wear resistance |

|

ACM |

-25°C to +150°C |

Transmission oils, oxidized oils |

Superior heat resistance |

|

EPDM |

-50°C to +150°C |

Brake fluids, steam, polar fluids |

Not compatible with mineral oils |

The choice of material should align with the lubricant type, thermal conditions, and any exposure to aggressive chemicals or additives. The standard oil seal SC typically uses and NBR 70 shore A compound, which offers a strong balance between elastic, wear resistance, and compatibility with mineral oil-based lubricants. The garter springs, that are used to keep constant contact between sealing lip and rotating shaft, are commonly manufactured from carbon spring steel according to DIN EN 10270-1, or from stainless steel grade 1.4301 for enhanced corrosion protection.

SC oil seals require precise shaft and housing specifications in order to ensure optimal performance and prevent leakage. The recommended surface finish for the shaft lies between Ra 0.2 to 0.8 µm, while dynamic applications demand a shaft hardness of at least 45 HRC. When machining the housing bore you should match an ISO H8 tolerance, and the rotating shafts diameter must meet ISO H11 tolerance. These dimensional standards are essential to keep a reliably sealing. Especially for SC rotary shaft seals that rely entirely on their primary sealing lip for fluid retention, since there is no secondary sealing lip as in TC type oil seals.

Understanding the difference between SC and other shaft seal types helps in selecting the optimal profile:

In short, SC is the go-to profile when dust exclusion isn’t critical, but low friction and cost-efficiency are. For a broader selection, explore our complete range of general rotary shaft seals, covering multiple designs and material options for diverse industrial needs.

Many manufacturers use different naming conventions or legacy codes to refer to the SC profile. Here’s a cross-reference table with equivalents:

|

Manufacturer |

Profile Code |

|

Dichtomatik |

WA |

|

Anyseals |

OS-A10 |

|

B+S |

TR-A |

|

Chicago R |

HMS4 |

|

Elring |

A |

|

Eriks |

R |

|

FP Paris |

G |

|

FST |

BA |

|

Gaco |

A |

|

Goetze |

827 N |

|

Kaco |

DG |

|

Kramp |

CB |

|

National |

35 |

|

Paulstra |

IE |

|

Pioneer W |

R21 |

|

Rolf |

R |

|

Stefa |

CB |

|

Taiwan / NOK |

SC |

|

Vota |

BA |

|

Ebele |

R |

|

Kimman |

KA |

These equivalencies are helpful when replacing seals across international or legacy stock lists.

Oil seals SC perform best in interval environments where there are little to no contaminating risks and the focus is on lubricant retention. Because it’s compact design they are widely used in small to medium rotating assemblies, automotive pumps, and auxiliary devices. You’ll also find the SC rotary shaft seals in industrial rollers and conveyors due to their low-friction properties. Additionally, enclosed electric drive systems take advantage of their efficiency and reduced wear. Due to the simple structure of the oil seal SC, it’s simpler to install and it’s also a better economical choice than dual-lip variants, especially in situations where the added protection of a dust lip is unnecessary. For housings that require improved static retention due to bore imperfections or thermal cycling, a ribbed outer diameter alternative such as the G10 profile may be a more suitable choice. For higher temperature environments, the SC Plus - Viton oil seal provides the same design as SC but is manufactured from FKM material, ensuring greater heat resistance and durability.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

An SC oil seal has a single spring-loaded sealing lip and no dust lip, making it ideal for clean and enclosed systems. A TC oil seal includes a secondary dust lip for protection against contamination, but comes with slightly higher friction and heat generation due to its dual-lip design.

SC oil seals are not designed for pressurized systems and should only be used in applications with low or near-zero system pressure. If low pressure is present, it must remain within the manufacturer’s recommended range. For higher pressure applications, specially designed high-pressure shaft seals or profiles with reinforced lips are recommended.

SC seals perform well in standard housings as long as ISO H8 tolerances are maintained. Their elastomer-coated OD allows proper sealing even in housings with minor surface roughness, thermal expansion (e.g., light-metal housings), or when split housings are used.

The most common material is NBR for general lubrication and mineral oil compatibility. FKM, HNBR, Silicone (VMQ), ACM, and EPDM are available for higher temperatures, synthetic media, or chemically aggressive fluids. The correct material depends on temperature, lubrication type, chemical exposure, and shaft speed.

Choose an SC profile when you need low friction, low heat generation, and long service life in a clean, enclosed system without external contamination. Dual-lip designs such as TC or TB are better suited for dusty, wet, or abrasive environments where additional exclusion capability is needed.

Didn't find the right Oil Seal SC - Rotary Shaft Seal?

Complete the form below and we will help you!