| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Material Spring | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

79540 | Oil Seal | 179 | 194 | 7 | NBR - Nitrile | Yes | Yes | Black | 370 | € 24,58 | Details | ||||

|

79539 | Oil Seal | 174.63 | 200.03 | 14.28 | NBR - Nitrile | Yes | Yes | Black | 0 | € 22,61 | Details | Quote | |||

|

79538 | Oil Seal | L-DRAL | 165 | 185 | 15 | NBR - Nitrile | Yes | Yes | Black | 78 | € 21,48 | Details | |||

|

79537 | Oil Seal | 161.92 | 187.33 | 15.87 | NBR - Nitrile | Yes | Yes | Black | 145 | € 21,48 | Details | ||||

|

79536 | Oil Seal | 160 | 290 | 18 | FPM - VITON | Yes | Yes | Brown | 17 | € 157,75 | Details | ||||

|

79535 | Oil Seal | 160 | 220 | 12 | NBR - Nitrile | Yes | Yes | Black | 146 | € 26,04 | Details | ||||

|

79534 | Oil Seal | 160 | 174 | 7 | FPM - VITON | Yes | Yes | Brown | 0 | € 79,46 | Details | Quote | |||

|

79533 | Oil Seal | 154 | 180.98 | 12.7 | NBR - Nitrile | Yes | Yes | Black | 252 | € 21,48 | Details | ||||

|

79532 | Oil Seal | 152.4 | 196.85 | 9.52 | NBR - Nitrile | Yes | Yes | Black | 0 | € 24,58 | Details | Quote | |||

|

79531 | Oil Seal | 150 | 225 | 15 | FPM - VITON | Yes | Yes | Brown | 56 | € 109,20 | Details | ||||

|

79530 | Oil Seal | 149.23 | 174.63 | 12.7 | NBR - Nitrile | Yes | Yes | Black | 49 | € 19,30 | Details | ||||

|

79529 | Oil Seal | 148 | 200 | 18 | NBR - Nitrile | Yes | Yes | Black | 0 | € 24,58 | Details | Quote | |||

|

79528 | Oil Seal | 146.05 | 225.43 | 19.05 | NBR - Nitrile | Yes | Yes | Black | 0 | € 29,46 | Details | Quote | |||

|

79527 | Oil Seal | 145 | 184 | 15 | FPM - VITON | Yes | Yes | Brown | 0 | € 80,16 | Details | Quote | |||

|

79526 | Oil Seal | 145 | 175 | 12 | FPM - VITON | Yes | Yes | Brown | 265 | € 79,46 | Details | ||||

|

79525 | Oil Seal | 145 | 170 | 20 | NBR - Nitrile | Yes | Yes | Black | 0 | € 18,05 | Details | Quote | |||

|

79524 | Oil Seal | W-DRAL | 140 | 210 | 15 | NBR - Nitrile | Yes | Yes | Black | 0 | € 22,61 | Details | Quote | ||

|

79523 | Oil Seal | 140 | 153 | 9 | FPM - VITON | Yes | Yes | Brown | 125 | € 69,58 | Details | ||||

|

79522 | Oil Seal | 139.7 | 158.75 | 12.7 | FPM - VITON | Yes | Yes | Brown | 157 | € 69,58 | Details | ||||

|

79521 | Oil Seal | 135 | 190 | 15 | NBR - Nitrile | Yes | Yes | Black | 8 | € 21,48 | Details | ||||

|

79520 | Oil Seal | 135 | 185 | 13 | NBR - Nitrile | Yes | Yes | Black | 0 | € 21,48 | Details | Quote | |||

|

79519 | Oil Seal | 129.39 | 155.57 | 12.7 | NBR - Nitrile | Yes | Yes | Black | 93 | € 16,70 | Details | ||||

|

79518 | Oil Seal | L-DRAL | 128 | 148.2 | 10 | NBR - Nitrile | Yes | Yes | Black | 0 | € 15,59 | Details | Quote | ||

|

79517 | Oil Seal | 125.43 | 152.4 | 12.7 | FPM - VITON | Yes | Yes | Brown | 149 | € 69,58 | Details | ||||

|

79516 | Oil Seal | 125 | 160 | 18 | NBR - Nitrile | Yes | Yes | Black | 180 | € 16,70 | Details | ||||

|

79515 | Oil Seal | 122.25 | 150.01 | 12.7 | NBR - Nitrile | Yes | Yes | Black | 0 | € 16,70 | Details | Quote | |||

|

79514 | Oil Seal | L-DRAL | 122.25 | 140.89 | 11.91 | NBR - Nitrile | Yes | Yes | Black | 203 | € 14,75 | Details | |||

|

79513 | Oil Seal | 120.65 | 158.75 | 12.7 | NBR - Nitrile | Yes | Yes | Black | 50 | € 16,70 | Details | ||||

|

79512 | Oil Seal | W-DRAL | 120 | 180 | 13 | NBR - Nitrile | Yes | Yes | Black | 194 | € 19,30 | Details | |||

|

79511 | Oil Seal | 120 | 150 | 11 | NBR - Nitrile | Yes | Yes | Black | 0 | € 15,59 | Details | Quote |

TC oil seals are made in a few different elastomers and each of these materials behave a bit differently. Some of these rotary shaft seals can resist a higher temperature and others are better compatible with oils or specific chemicals. If you want to choose the best seal, you’ll have to consider where you’re going to use it and what conditions the seal will have to withstand.

|

Material |

Temperature Range |

Suitable For |

Notes |

|

NBR (Nitrile) |

−40°C to +100°C |

Mineral oils, general industry |

Standard and most cost-effective option |

|

FKM / Viton |

up to +200°C |

High temperature, chemicals |

Offered as oil seal TC Plus for demanding conditions |

|

HNBR |

−30°C to +150°C |

Higher loads, improved oil resistance |

Suitable for heavy-duty machinery |

|

ACM |

−20°C to +150°C |

Automotive oils, ATF fluids |

Good heat and oil resistance |

|

Silicone (VMQ) |

−60°C to +150°C |

Low-temperature environments |

Limited oil and wear resistance |

|

EPDM / CR |

Application-specific |

Water, steam, certain chemicals |

Not compatible with mineral oils |

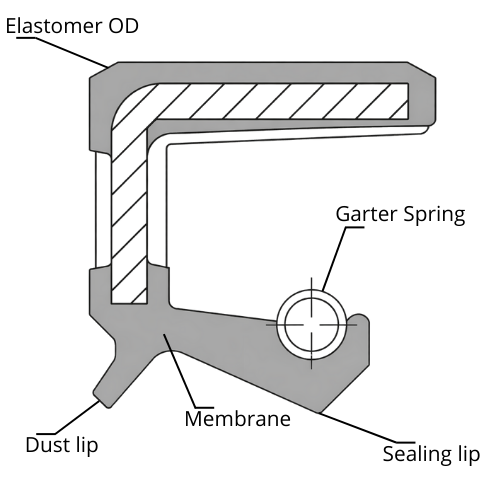

Usually, the metal case is made of carbon steel but when corrosion is a concern, you could choose to use stainless steel. The spring inside the rotor seal follows the same idea. Some of these are made of spring steel but others are made of stainless steel due to a harsher environment. Which materials you should use really depends on the machine and how clean or dirty the process is.

As seen in practical situations, TC oil seals work best when their limits are not being surpassed. In most situations, a standard seal can deal with temperatures between -40°C and +100°C. Although the seal could handle temperatures up to +100°C, it’s usually better to stay around +80°C because higher heats shorten the seal’s lifetime quiet a bit. Also, these seals are not meant for high-pressure applications as they can only handle pressure up to roughly 0.05 MPa. The allowed shaft speed depends on a few things, like the seal size, the shaft surface and how thick the lubricant is.

Oil seal TC run well with mineral oil-based lubricants and with many synthetic oils too. If there is no information available about a certain lubricant, it is safer to check the compatibility first before using it.

For optimal performance, the shaft should follow ISO h11 tolerances and offer a hardened, lead-free surface of at least 45 HRC. A surface roughness between Ra 0.2 and 0.8 μm ensures the proper lubrication film for the primary lip. The housing bore should be machined to ISO H8 tolerance with a roughness of Ra 1.6 to 6.3 μm, allowing the rubber-coated outer diameter to form a secure static seal. When these conditions are met, an oil seal TC achieves maximum stability and lifespan.

TC oil seals are often compared to other profiles such as SC and TB. An SC seal uses only a single sealing lip and is therefore more suited to clean environments. TB seals share the double-lip configuration but typically use a different case design and may not include the same elastomer-coated OD features. In general, the TC seal is chosen when contamination is present, when static sealing requirements are higher, or when the housing material benefits from an elastomeric interface.

Many manufacturers use their own codes for the TC oil seal. Although the design is the same, a double-lip radial shaft seal with a rubber-coated outer diameter, the naming can differ per brand or catalog system. The table below shows the most common alternative designations used worldwide, making it easier to match a rotor oil seal TC to another supplier’s reference.

|

Fabrikant / merk |

Code(s) / typebenamingen |

|

Dichtomatik |

WAS |

|

Anyseals |

OS-A11 |

|

B+S |

TR-E |

|

Chicago (R) |

HMSA7 |

|

Elring |

AS |

|

Eriks |

RST |

|

FP Paris |

GP |

|

FST |

BA SL |

|

Gaco |

FA |

|

Goetze |

827 S |

|

Kaco |

DGS |

|

Kramp |

CC |

|

National |

32 |

|

Paulstra |

IEL |

|

Pioneer W |

R23 |

|

Rolf |

RP |

|

Stefa |

CC |

|

Taiwan / NOK |

TC |

|

Vota |

BA SL |

|

Ebele |

RP |

|

Kimman |

KAS |

Because they keep out dust so well, oil seal TC are widely used in agricultural machines, construction equipment, transport systems, industrial gearboxes and electric motors. The rubber coated outside together with the dual lip setup gives the seal enough stability to keep working even when the machine deals with dirt, vibration, humidity or changing loads during normal operation. For many technicians and engineers, the TC seal profile is simply the usual choice when long term reliability matters and when the surroundings are not clean enough for more delicate sealing options.

Selecting the appropriate rotary shaft seal involves matching the elastomer to the operating fluid and temperature, confirming shaft and housing tolerances, and evaluating the level of contamination present in the application. NBR variants are ideal for most general industrial systems, while FKM (Viton) versions are preferred for elevated temperatures or chemically aggressive media. When the housing requires increased static grip, a ribbed outer-diameter style such as the G11 seal may be more suitable.

Our TC oil seals are available in a wide range of sizes, elastomers and case materials. You can use the filters on this page to choose the inner diameter, outer diameter, width and compound that best fit your application. Whether you require NBR for standard use or FKM for higher temperatures, the oil seal TC design ensures dependable sealing performance in demanding, contaminated environments.

If you would like more information about this oil-seal or you don't know what size or material you should have, please feel free to contact us.

A TC type oil seal is a double-lip rotary shaft seal designed to keep lubricants inside a machine while blocking dust, dirt and moisture from entering. It has a spring-loaded main lip for oil retention and a secondary dust lip for contamination protection.

A TC oil seal has two lips (main lip + dust lip), making it better for dirty or outdoor environments. An SC oil seal has only one lip, so it is mainly used in clean, indoor applications where contamination is low.

Both TC seals and TB seals are double-lip designs, but the TC seal type has a rubber-coated outer diameter, which provides better static sealing, especially in aluminum housings or housings affected by thermal expansion. TB seals usually have a metal outer case.

TC type rotary shaft seals are made for low-pressure applications. They can typically handle up to 0.05 MPa (about 0.5 bar). If the system has higher pressure, a high-pressure seal or a different design is required.

Didn't find the right Oil Seal TC - Rotary Shaft Seal?

Complete the form below and we will help you!