| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

75868 | Oil Seal | 46 | 59.1 | 12 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,36 | Details | ||

|

75674 | Oil Seal | 40 | 50 | 5.5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 4,48 | Details | ||

|

75706 | Oil Seal | 40 | 62 | 6.5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,08 | Details | ||

|

75732 | Oil Seal | 41 | 51 | 5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 4,98 | Details | ||

|

75734 | Oil Seal | 41 | 54 | 5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 4,95 | Details | ||

|

75749 | Oil Seal | 42 | 56.2 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,45 | Details | ||

|

75751 | Oil Seal | 42 | 60 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,36 | Details | ||

|

75758 | Oil Seal | 42 | 64 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,08 | Details | ||

|

75780 | Oil Seal | 43 | 55 | 7.5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 4,95 | Details | ||

|

75781 | Oil Seal | 43 | 56 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,45 | Details | ||

|

75810 | Oil Seal | 45 | 52 | 4 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 4,98 | Details | ||

|

75844 | Oil Seal | 45 | 72.2 | 7.5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,99 | Details | ||

|

75867 | Oil Seal | 46 | 59 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,36 | Details | ||

|

75625 | Oil Seal | 38 | 62 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,08 | Details | ||

|

75878 | Oil Seal | 46.2 | 80 | 7 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,77 | Details | ||

|

75907 | Oil Seal | 48 | 62 | 11 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 6,08 | Details | ||

|

75918 | Oil Seal | 48 | 72 | 8 | FPM - VITON | Steel | No | Yes | Brown | 224 | € 20,68 | Details | ||

|

75943 | Oil Seal | 50 | 60 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 5,36 | Details | ||

|

76141 | Oil Seal | 6 | 19 | 4 | FPM - VITON | Steel | No | Yes | Brown | 0 | € 9,45 | Details | Quote | |

|

76142 | Oil Seal | 6 | 19 | 4 | NBR - Nitrile | Steel | No | Yes | Black | 227 | € 2,41 | Details | ||

|

76514 | Oil Seal | 95 | 105 | 5 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 9,58 | Details | ||

|

79573 | Oil Seal | 12 | 20 | 5 | NBR - Nitrile | Steel | No | Yes | Green | 436 | € 2,41 | Details | ||

|

79580 | Oil Seal | 25 | 33 | 6 | NBR - Nitrile | Steel | No | Yes | Green | 183 | € 2,79 | Details | ||

|

79584 | Oil Seal | 30 | 47 | 4 | NBR - Nitrile | Steel | No | Yes | Green | 373 | € 4,17 | Details | ||

|

79592 | Oil Seal | 35 | 42 | 4 | NBR - Nitrile | Steel | No | Yes | Green | 0 | € 3,70 | Details | Quote | |

|

74871 | Oil Seal | 20 | 28 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 2,41 | Details | ||

|

74253 | Oil Seal | 100 | 152 | 12 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 19,19 | Details | ||

|

74301 | Oil Seal | 11 | 16 | 4 | NBR - Nitrile | Steel | No | Yes | Black | 1198 | € 2,41 | Details | ||

|

74359 | Oil Seal | 12 | 16 | 3 | NBR - Nitrile | Steel | No | Yes | Black | 1569 | € 2,41 | Details | ||

|

74366 | Oil Seal | 12 | 20 | 6 | NBR - Nitrile | Steel | No | Yes | Black | 224 | € 2,41 | Details |

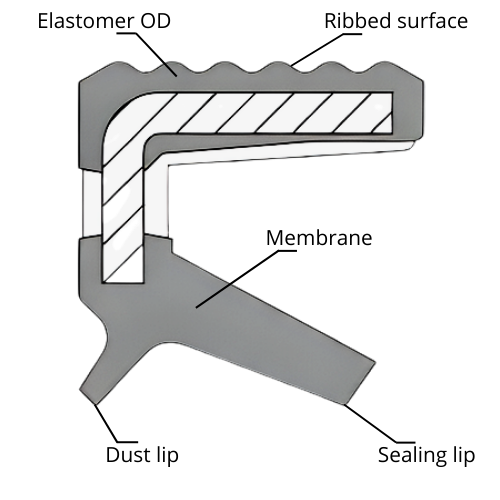

A KG oil seal is a radial shaft seal for rotating shafts, specially engineered without a garter spring. It consists of a reinforced metal inner ring that is fully covered with rubber. The ribbed rubber outer diameter provides excellent static sealing, even in housings that are less precise or subject to thermal expansion. The oil seal KG contains two sealing lips: one main lip which retains lubricants and one dust lip which protects the main seal from external contaminations like dirt of moisture. By excluding the garter spring, the KG oil seal is ideal for applications with low friction and limited space available. This makes the oil seal KG suitable for low maintenance, pressureless systems.

KG oil seals are widely used in sectors where grease or oil lubrication is required without pressure build-up. They are commonly found in electric motors, where they prevent grease leakage and block contaminants from entering the bearings. In gearboxes, they protect the bearing chamber from dust. They are also used in pumps and fans where moderate rotational speeds and low-pressure levels occur. In agricultural and construction machinery they are applied in rotating components exposed to dust and moisture. They are further used in general machinery and equipment manufacturing, especially where a compact seal is needed in small spaces or aluminium housings. Thanks to the dust lip, the KG rotary shafts are ideal for applications with lightly contaminated environments and applications requiring both internal and external sealing protection.

A key characteristic of the KG oil seal is its springless design. Without a garter spring, friction is reduced, and the overall structure is simplified. The seal features two sealing lips: a primary sealing lip and a dust lip that provides additional protection against external contamination. The rubber-coated metal reinforcement with ribbed outer diameter adapts well to rough or expanding bores. Because the outer diameter is fully rubber-encapsulated, the KG seal eliminates the risk of fitting corrosion between the seal and the housing bore. Its compact design makes this seal suitable for applications with limited installation space. The KG oil seal is also maintenance-free and suitable for long-term grease sealing without intervention.

When comparing the KG oil seal with other types, the differences become clear. The VG rotary shaft seal has a single lip without a dust lip, a ribbed rubber outer diameter, and is also springless like the KG seal. It is suitable for clean environments where low friction is a priority. The KC seal features a double lip with a dust lip, like the KG type, but has a smooth rubber outer diameter. It is designed for precise, smooth bores in steel or cast-iron housings. The oil seal KG distinguishes itself by offering better adaptability to rougher or thermally active bores, for example, in aluminium, thanks to its ribbed outer mantle.

Several factors play a role when selecting the correct KG oil seal. The shaft and the housing dimensions must match standard tolerances like ISO H11 for the shaft and ISO H8 for the bore. For optimal sealing performance, the shaft should have a minimum hardness of 45 HRC and a surface roughness between Ra 0.2–0.8 µm (Rz 1–5 µm). The housing bore should maintain a roughness of Ra 1.6–6.3 µm (Rz 10–20 µm), ensuring a secure static seal even under thermal or mechanical load. The temperature range which the oil seal KG has to perform in depends on the material of the sealing lip. The reinforcement ring is typically manufactured from sheet steel according to DIN EN 10139, with stainless steel 1.4301 available for applications requiring enhanced corrosion resistance. In its standard material configuration, the KG oil seal operates reliably between –40°C and +100°C. When used with synthetic lubricants for which no compatibility data is available, laboratory or practical testing is recommended, and the operating temperature should not exceed 80°C. Also, the lubricants must be compatible with the elastomer type of the oil seal, especially with synthetic lubricants. When using the KG oil seal, the shafts maximum rotating speed should not exceed approximately 6 m/s. In contaminated environments, a double lip solution like the KG is preferred, while a single lip sealing like the VG should be sufficient in clean environments. The installation space also plays its role: thanks to the compact design, the KG oil seal is suitable for applications with limited mounting depth.

Below you find an overview of the most used materials and their maximum temperatures and most important benefits:

|

Material |

Max Temperature |

Advantages |

|

NBR (standard) |

100°C |

Good oil and grease resistance, economical |

|

FKM (Viton®) |

200°C |

Excellent heat and chemical resistance |

|

HNBR |

150°C |

High wear resistance, better high-temperature performance |

|

ACM |

150°C |

Good resistance to oxidation and oil |

|

Silicone (VMQ) |

180°C |

Excellent temperature range, low friction |

|

CR |

120°C |

Good weather resistance |

|

EPDM |

140°C |

Resistant to steam and water, not suitable for oil |

A KG seal is springless and has a double lip with a dust lip, making it ideal for grease sealing in pressure-free systems. Standard oil seals usually contain a garter spring and are designed for applications involving higher pressures.

It can be used up to approximately 6 m/s. For higher speeds, spring-loaded seals or PTFE lip seals are more suitable.

OS-G13 is an alternative designation for the KG seal with a ribbed outer diameter. OS-A13 refers to the smooth-outer-diameter variant.

Yes. The ribbed rubber outer diameter compensates for thermal expansion and surface irregularities, making it ideal for aluminium housings.

Didn't find the right Oil Seal KG - Rotary Shaft Seal?

Complete the form below and we will help you!